Preparation method of graphene-loaded nano nickel phosphate hydrogenation catalyst

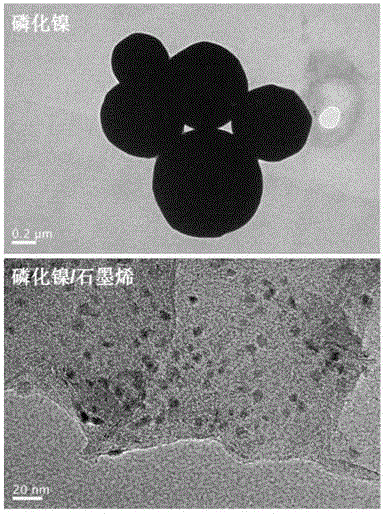

A hydrogenation catalyst, nickel phosphide technology, applied in physical/chemical process catalysts, chemical instruments and methods, hydrogenation to hydrocarbons, etc., can solve the complex preparation conditions of transition metal phosphide, the catalytic activity cannot be fully exerted, and the particle agglomeration is serious. and other problems, to achieve good catalytic activity and reusability, excellent stability and corrosion resistance, and the effect of eliminating internal diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Weigh a certain amount of graphite oxide and add it to deionized water, so that the concentration of graphite oxide is 2mg / mL, ultrasonic treatment 3 times, each time for 0.5h, to obtain a stably dispersed aqueous solution of graphene oxide; add 1mmol hypophosphorous acid to the above solution Sodium dihydrogen and 0.5mmol nickel chloride, stirred at room temperature for 1h, put the mixed solution into a polytetrafluoroethylene crystallization kettle, crystallized at 150°C for 20h, centrifuged after crystallization, and washed the sample fully with deionized water, 80 ℃ drying to obtain the catalyst A.

Embodiment 2

[0024] Using graphene as a carrier, a highly dispersed nickel phosphide / graphene catalyst was prepared by a hydrothermal method. Weigh a certain amount of graphite oxide and add it to deionized water, so that the concentration of graphite oxide is 2mg / mL, ultrasonic treatment 3 times, each time for 0.5h, to obtain a stable dispersed graphene oxide aqueous solution; add 6mmol hypophosphorous acid to the above solution Sodium dihydrogen and 2mmol nickel chloride, stirred at room temperature for 1h, put the mixed solution into a polytetrafluoroethylene crystallization kettle, crystallized at 170°C for 15h, centrifuged after crystallization, washed the sample fully with deionized water, 80°C drying to obtain the catalyst B.

Embodiment 3

[0026] Using graphene as a carrier, a highly dispersed nickel phosphide / graphene catalyst was prepared by a hydrothermal method. Weigh a certain amount of graphite oxide and add it to deionized water, so that the concentration of graphite oxide is 2mg / mL, ultrasonic treatment 3 times, each time for 0.5h, to obtain a stable dispersed graphene oxide aqueous solution; add 6mmol hypophosphorous acid to the above solution Sodium dihydrogen and 2mmol nickel chloride, stirred at room temperature for 1h, put the mixed solution into a polytetrafluoroethylene crystallization kettle, crystallized at 190°C for 5h, centrifuged after crystallization, washed the sample fully with deionized water, 80°C drying to obtain the catalyst C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com