Preparation method of nano-iron modified zeolite

A modified zeolite and nano-iron technology, which is applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the problems of small adsorption capacity, large dosage of high-concentration ammonia nitrogen, increased transportation costs, etc. problem, to achieve the effect of improving the adsorption capacity of ammonia nitrogen, simple preparation process and large adjustable range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

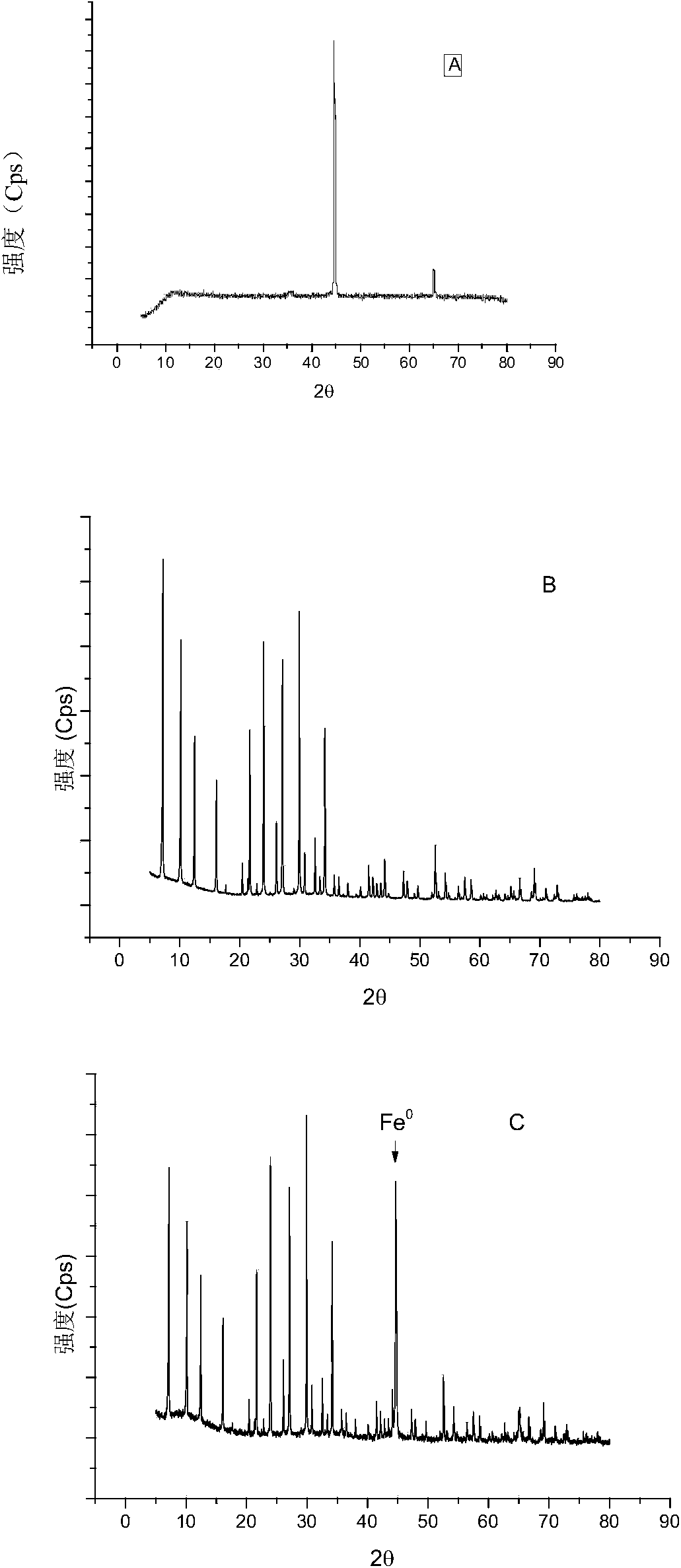

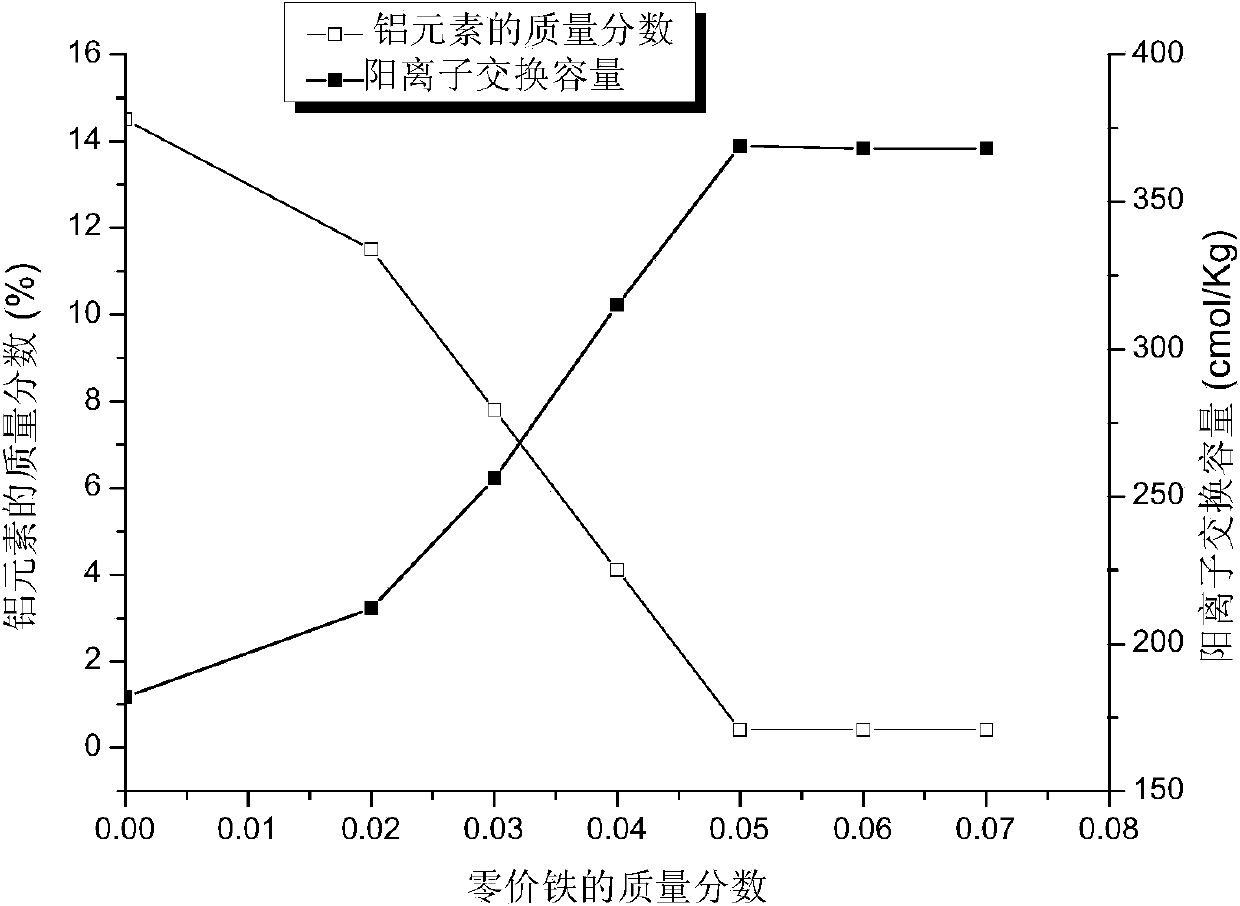

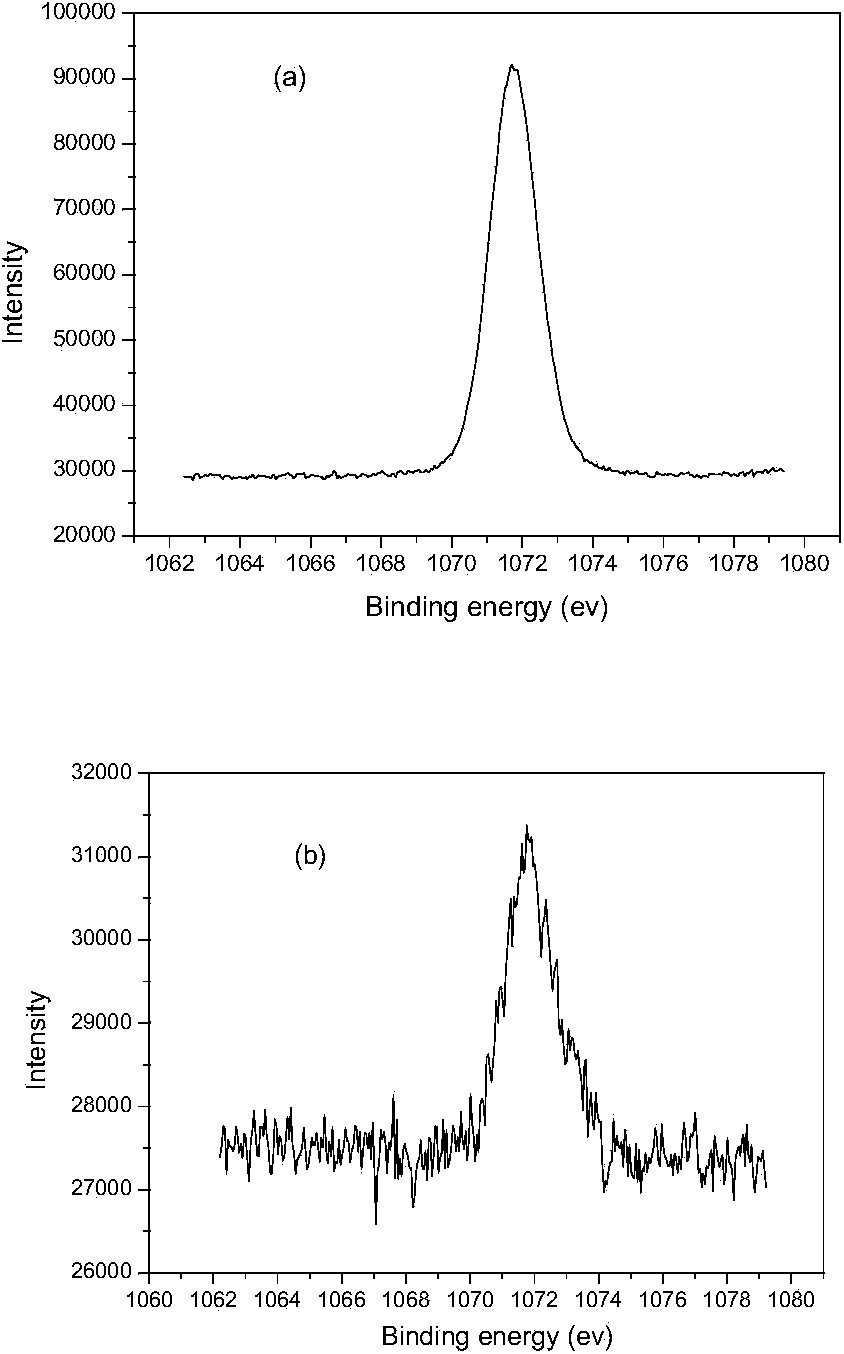

[0031] Disperse 10.2 g of clinoptilolite in 200 mL of 5 mol / L NaOH solution and stir at 90° C. for 5 hours to form a hydrogel. Mix 0.4 g of nano-iron with it, stir evenly, put the material into a reaction kettle lined with polytetrafluoroethylene, and crystallize at 90° C. for 6 hours. Then filter, wash, and dry at 60°C for 24 hours. Through nitrogen adsorption and desorption and infrared spectroscopic analysis, the nano-iron is attached to the micropore wall of the zeolite.

Embodiment 2

[0033] Disperse 12.5 g of artificial zeolite 13X zeolite in 100 mL of 2 mol / L NaOH solution, and stir at 80° C. for 1 hour to form a hydrogel. Then add 0.4 g of nano-iron, stir evenly, put the material into a reaction kettle lined with polytetrafluoroethylene, and crystallize at 90° C. for 8 hours. Then filter, wash, and dry at 60°C for 24 hours. Through nitrogen adsorption and desorption and infrared spectroscopic analysis, the nano-iron is attached to the micropore wall of the zeolite.

Embodiment 3

[0035] Disperse 10.5 g of artificial zeolite 4A zeolite in 100 mL of 2 mol / L NaOH solution and stir at 80° C. for 1 hour to form a hydrogel. Then add 0.4 g of nano-iron, stir evenly, put the material into a reaction kettle lined with polytetrafluoroethylene, and crystallize at 99° C. for 3-4 hours. Then filter, wash, and dry at 60°C for 24 hours. Through nitrogen adsorption and desorption and infrared spectroscopic analysis, the nano-iron is attached to the micropore wall of the zeolite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com