Preparation method of nano porous copper

A nanoporous copper technology, applied in the field of alloy manufacturing, can solve the problems of unsuitability for large-scale industrial production, complex preparation process operation, and long production cycle, and achieve low cost of preparation equipment, simple preparation process operation, and short cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

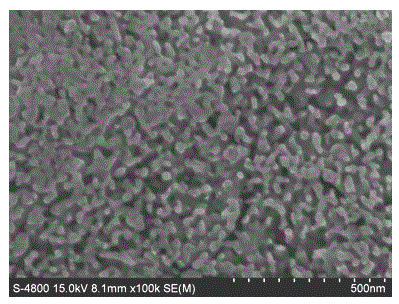

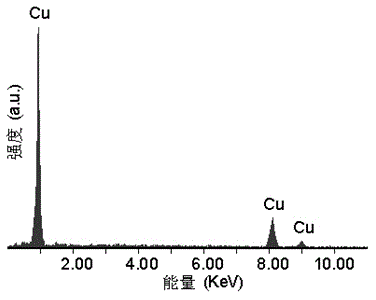

Embodiment 1

[0025] The first step is to prepare Cu-Hf-Al master alloy ingot

[0026] According to the atomic percentage of each element in the target alloy: Cu is 50.00%, Hf is 45.00% and Al is 5.00%, calculate the quality of required raw material, take by weighing the copper sheet 158.87g that mass percentage purity is 99.99%, mass percentage purity is 401.61g of 99.99% hafnium particles and 6.75g of aluminum block with a mass percentage purity of 99.99%, and mix the weighed copper sheet, hafnium particles and aluminum block to obtain the master alloy raw material; then place the master alloy raw material in a vacuum electric arc furnace In the process, 7g of pure zirconium was independently placed in a vacuum electric arc furnace without contact with the master alloy, and was used as a deoxidizing material to melt under the protection of argon. The melting current was gradually increased from 30A to 110A, and the melting was repeated 4 times, each time 38 Seconds, to ensure the homogene...

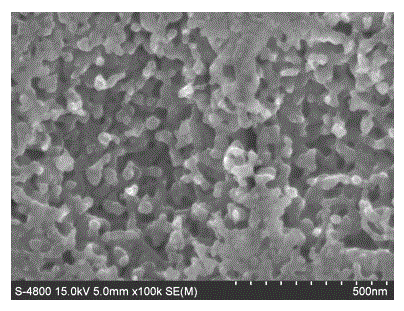

Embodiment 2

[0034] The first step is to prepare Cu-Hf-Al master alloy ingot

[0035] According to the atomic percentage of each element in the target alloy: Cu is 52.50%, Hf is 40.00% and Al is 7.5%, calculate the quality of required raw material, take by weighing the copper flake 166.81g that mass percentage purity is 99.99%, mass percentage purity is 356.98g of 99.99% hafnium particles and 10.13g of aluminum block with a mass percentage purity of 99.99%, and mix the weighed copper sheet, hafnium particles and aluminum block to obtain the master alloy raw material; then place the master alloy raw material in a vacuum electric arc furnace In the process, 7g of pure zirconium was independently placed in a vacuum electric arc furnace without contact with the master alloy, and was used as a deoxidizing material to melt under the protection of argon. The melting current was gradually increased from 30A to 110A, and the melting was repeated 4 times, each time 40 Seconds, to ensure the uniformi...

Embodiment 3

[0043] The first step is to prepare Cu-Hf-Al master alloy ingot

[0044] According to the atomic percentage of each element in the target alloy: Cu is 55.00%, Hf is 42.50% and Al is 2.5%, calculate the quality of required raw material, take by weighing the copper flake 174.75g that mass percentage purity is 99.99%, mass percentage purity is 379.29g of 99.99% hafnium particles and 3.38g of aluminum block with a mass percentage purity of 99.99%, and mix the weighed copper sheet, hafnium particles and aluminum block to obtain the master alloy raw material; then place the master alloy raw material in a vacuum electric arc furnace In the process, 7g of pure zirconium was independently placed in a vacuum electric arc furnace without contact with the master alloy, and was used as a deoxidizing material to melt under the protection of argon. The melting current was gradually increased from 30A to 110A. Seconds, to ensure the uniformity of the alloy structure, cooling with the furnace ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com