Ultraviolet light-cured self-cleaning coating, and preparation method and application thereof

A technology of ultraviolet light and photocatalytic materials, applied in the field of ultraviolet light curing self-cleaning paint and its preparation, can solve the problems of insufficient self-cleaning ability, pollution of exterior wall finishes, affecting the aesthetics and durability of buildings, etc., and achieve self-cleaning Good performance, good scratch resistance, small production site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

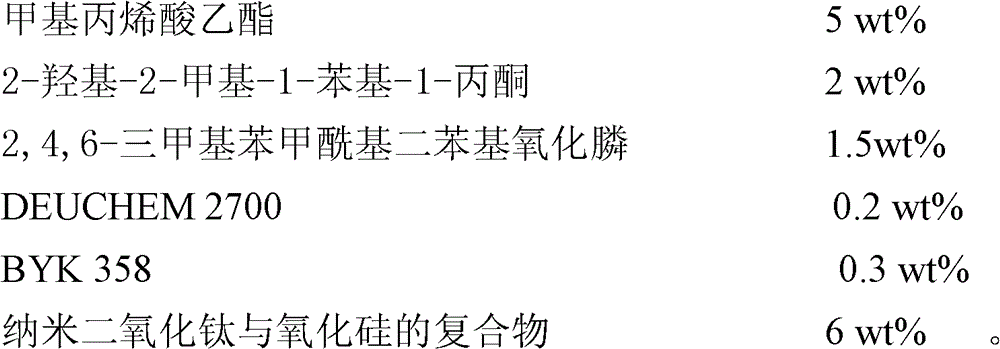

[0040] (1) The pure acrylate copolymer of 30wt% of the total system, 50wt% of polyurethane methacrylate, 5wt% of isooctyl acrylate, 5wt% of ethyl methacrylate and 2wt% of 2-hydroxyl-2 - Mix methyl-1-phenyl-1-propanone and 1.5wt% 2,4,6-trimethylbenzoyldiphenylphosphine oxide photoinitiator, heat up to 50-60°C, and stir to obtain a mixture ;

[0041] (2) Add DEUCHEM 2700 and 0.3wt% BYK 358 accounting for 0.2wt% of the total system to the system of step (1), stir, then add the compound (nanoparticle titanium dioxide and silicon oxide) accounting for 6wt% of the total system The weight ratio of particle titanium dioxide to silicon oxide is 9:1), and the mixture is fully stirred until completely dissolved, dispersed, ground, and filtered to obtain a UV-curable high-gloss self-cleaning coating.

[0042]

[0043]

Embodiment 2

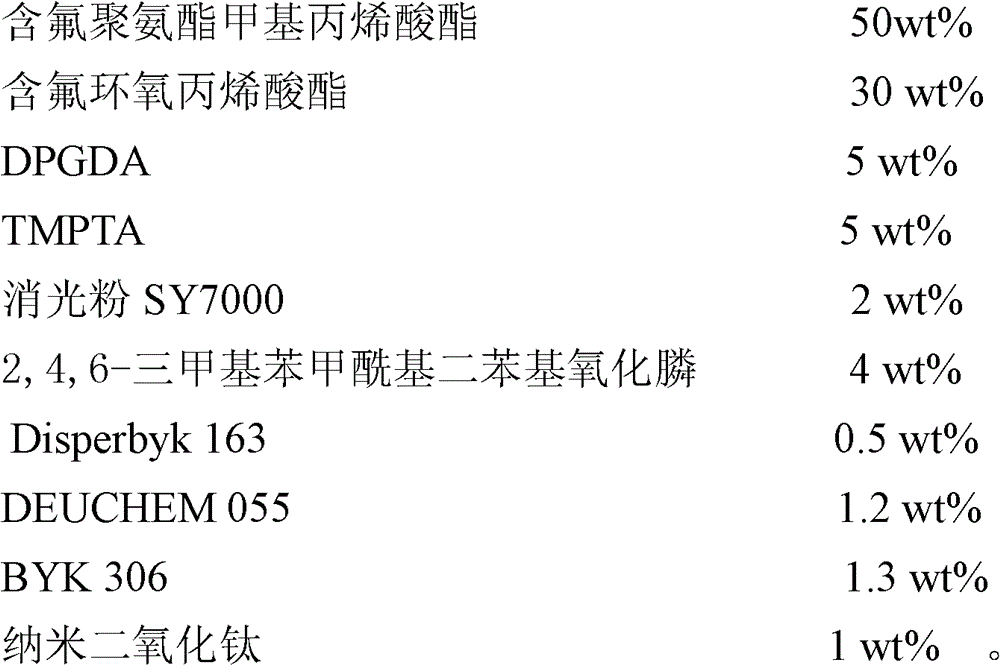

[0045] (1) The fluorine-containing polyurethane methacrylate of 50wt% of the total system, the fluorine-containing epoxy acrylate of 30wt%, the DPGDA of 5wt%, the TMPTA of 5wt% and the 2,4,6-trimethyl Mix the benzoyl diphenylphosphine oxide photoinitiator, heat up to 50-60°C, and stir evenly to obtain the mixture;

[0046] (2) Add 0.5wt% of Disperbyk 163, 1.2wt% of DEUCHEM 055 and 1.3wt% of BYK306 to the system of step (1), and stir until completely dissolved;

[0047] (3) Add 2wt% matting powder SY7000 and 1wt% nano-titanium dioxide to the system in step (2), stir, disperse, grind, and filter to obtain a UV-curable matte self-cleaning fluorocarbon coating.

[0048]

Embodiment 3

[0050] (1) The fluorine-containing acrylic copolymer accounting for 10wt% of the total system, the fluorine-containing polyester methacrylate of 4wt%, the fluorine-containing aminoacrylate of 10wt%, the TPGDA of 8wt%, the EO-TMPTA of 8wt%, 10wt% % dodecafluoroheptyl acrylate and 3wt% 2,4,6-trimethylbenzoyl diphenyl phosphine oxide, 2wt% 2-isopropylthioxanthone photoinitiator mix, warming up to 50 ~60°C, stir evenly to obtain a mixture;

[0051] (2) Add 1wt% of Disperbyk 163, 1wt% of BYK 055, and 1wt% of BYK306 to the system in step (1), and stir until completely dissolved;

[0052] (3) Add 12wt% talcum powder, 18wt% titanium dioxide, 10wt% phthalocyanine blue, 2wt% nano titanium dioxide to the system of step (2), stir, disperse, grind, filter, Obtained UV-curable blue self-cleaning fluorocarbon coating.

[0053]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com