Solvent-free epoxy self-leveling floor paint, preparation method thereof and using method thereof

A solvent-free and coating technology, applied in the direction of epoxy resin coating, coating, construction, etc., can solve the problems that it is difficult to meet the decorative requirements of commercial and civil buildings, the color of the floor coating is monotonous, and the decorative performance is poor. Improves strength, improves aesthetics, and improves comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

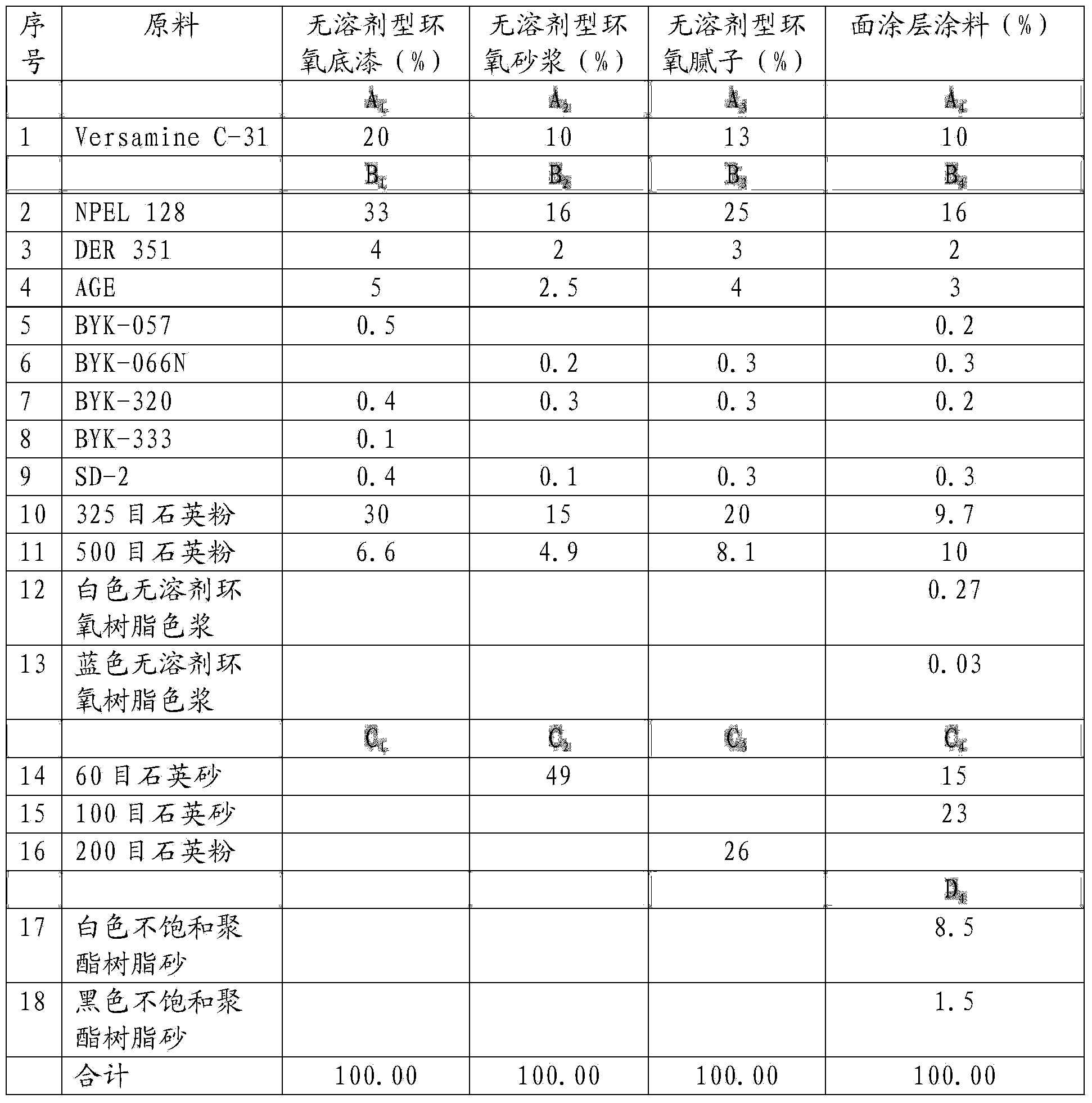

[0047] The raw material ratio of top coat paint, solvent-free epoxy primer, solvent-free epoxy mortar, and solvent-free epoxy putty is shown in Table 1.

[0048] The raw material ratio of each coating coating in table 1 embodiment 1

[0049]

[0050] According to the above table, by using different colors of epoxy resin color paste and different colors of unsaturated polyester resin sand, top coat paints with different colors can be prepared.

[0051] The preparation method of solvent-free epoxy primer: first, stir low molecular weight bisphenol A liquid epoxy resin, low molecular weight bisphenol F type liquid epoxy resin and reactive diluent at a speed of 300-500r / min for 5-10min Mix evenly, then add additives at a speed of 500-800r / min, stir for 5-10min to mix evenly, then add quartz powder at a speed of 700-1300r / min, disperse at a high speed for more than 30min until the fineness is less than 100 microns, and filter and packed B 1 Components, the solvent-free modifie...

Embodiment 2

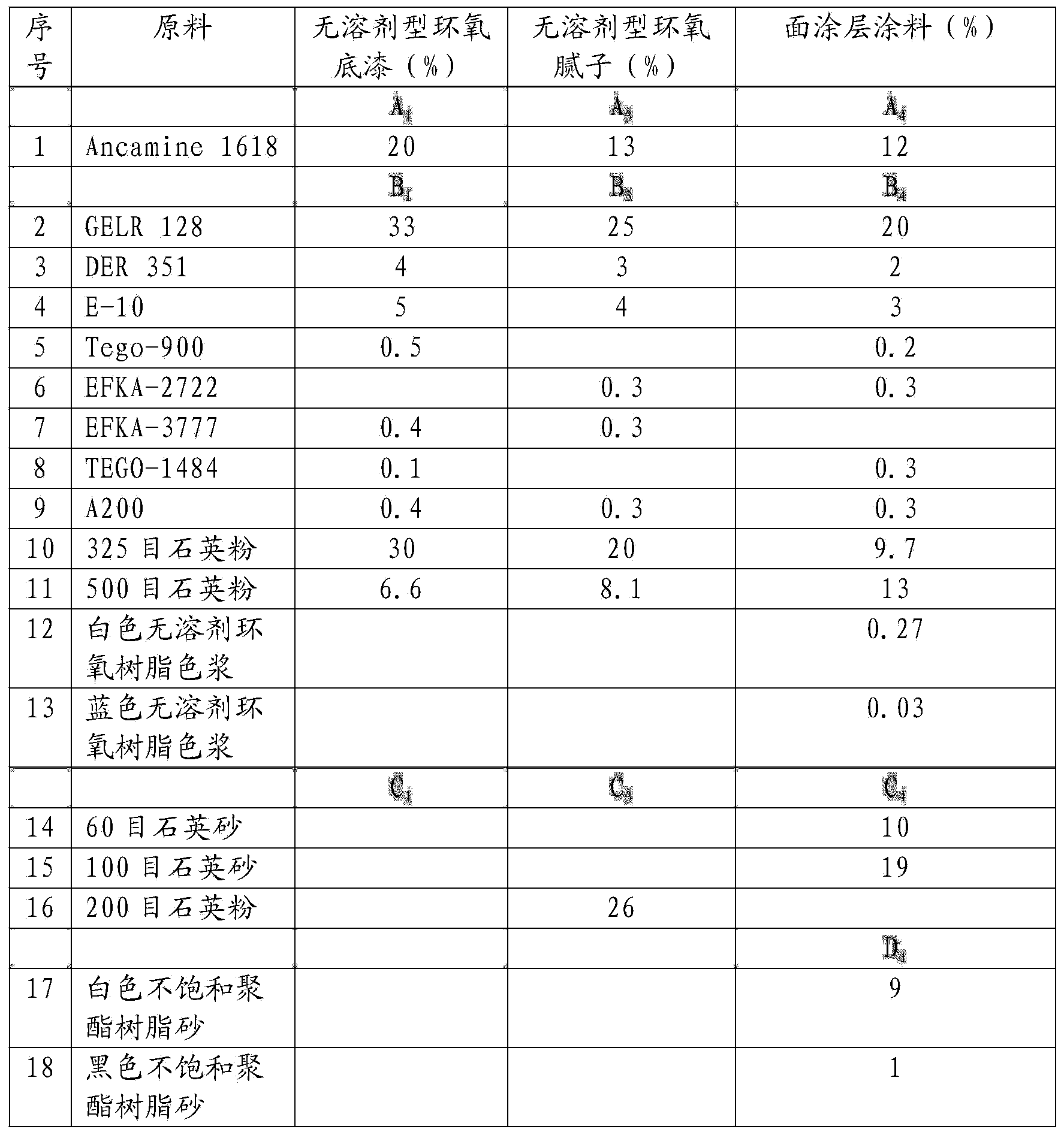

[0062] The raw material ratio of top coat paint, solvent-free epoxy primer, and solvent-free epoxy putty is shown in Table 2.

[0063] The raw material ratio of each coating coating in table 2 embodiment 2

[0064]

[0065]

[0066] In this example, the preparation methods of the top coat paint, the solvent-free epoxy primer, and the solvent-free epoxy putty are the same as those described in Example 1.

[0067] In this example, the difference between the method of using the above solvent-free epoxy self-leveling floor coating and the method described in Example 1 is that in step (2), after the primer layer is dry, no solvent-free coating is applied. Epoxy mortar, and the solvent-free epoxy putty is directly scraped and leveled on the base coat to form a leveling layer. The rest of the construction process is the same.

[0068] The solvent-free epoxy self-leveling colored sand floor is composed of a base coat, a leveling layer and a top coat, and its performance is sho...

Embodiment 3

[0070] The raw material ratio of top coat paint, solvent-free epoxy primer, and solvent-free epoxy putty is shown in Table 3.

[0071] The raw material ratio of each coating coating in table 3 embodiment 3

[0072]

[0073]

[0074] In this example, the preparation methods of the top coat paint, the solvent-free epoxy primer, and the solvent-free epoxy putty are the same as those described in Example 1.

[0075] In this embodiment, the method of using the above-mentioned solvent-free epoxy self-leveling floor paint is the same as that described in Embodiment 2.

[0076] The solvent-free epoxy self-leveling colored sand floor is composed of a base coat, a leveling layer and a top coat, and its performance is shown in Table 4.

[0077] Table 4 The performance test data of the solvent-free epoxy self-leveling colored sand floor formed by Examples 1-3

[0078]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com