System process for conducting efficient strengthened extraction in surrounding rock

A surrounding rock, high-efficiency technology, applied in the field of system technology for efficient and enhanced drainage in the surrounding rock, can solve the effect and efficiency requirements of unsuitable drainage, restrict the mining efficiency of soft coal seams in coal mines, and the long preparation time for roadway excavation, etc. problems, to achieve the effect of shortening the preparation time, improving the efficiency of coal seam mining, and increasing the rate of gas drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

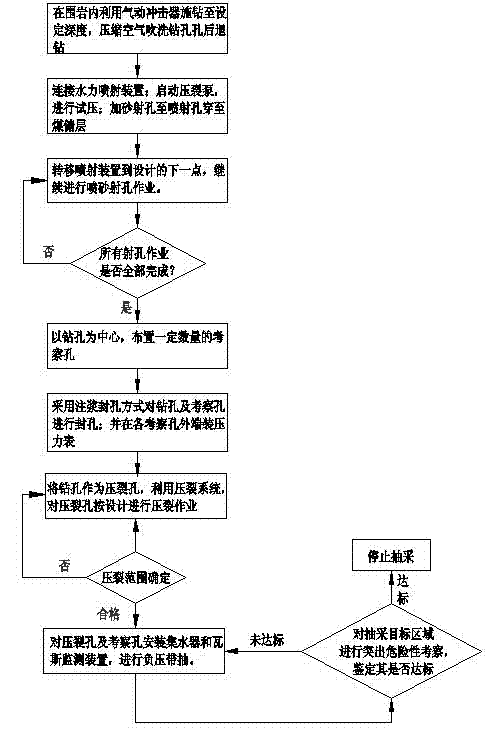

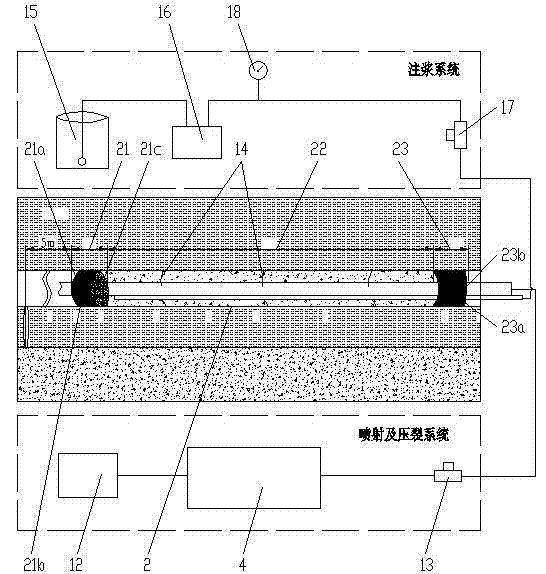

[0029] see figure 1 , figure 2 , image 3 , a systematic process for highly efficient enhanced drainage in surrounding rock 6, comprising the following steps:

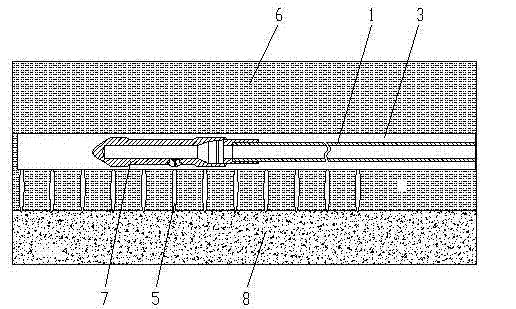

[0030] a. In the surrounding rock 6 of the coal reservoir 8 that is to be intensively extracted, i.e. the roof or floor, use a common drilling rig to install a pneumatic impactor through a hollow drill rod 1 to form a drilling tool and drill holes 3 and 3 as required. Finally, use compressed air to blow and wash the borehole 3, and then withdraw from the drilling tool;

[0031] b. Remove the pneumatic impactor and seal and fix the drill pipe 1 with the injection head 7 to form a hydraulic injection device, and send the injection head 7 to the set depth position in the borehole 3;

[0032] c. Connect the hydraulic injection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com