Horizontal well directional sand blasting perforation and fracturing integral tool pipe column and construction method thereof

A sandblasting perforating and tool tube technology, which is applied to drilling pipes, casings, production fluids, etc., can solve the problems of inability to solve directional perforation, incomplete introduction of downhole tools, etc., and achieves reliable, simple structure and practicality. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples cited are only used to explain the present invention, and are not used to limit the scope of the present invention.

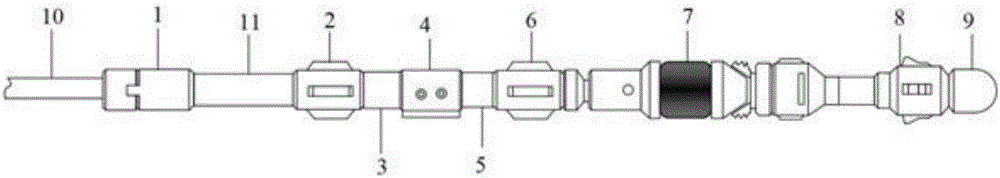

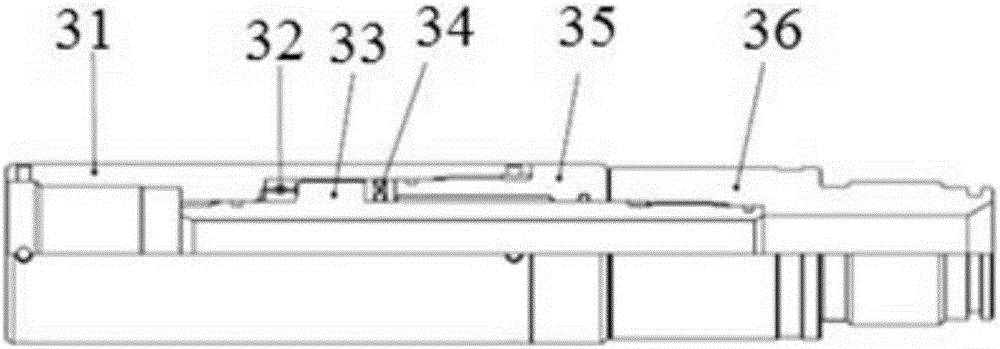

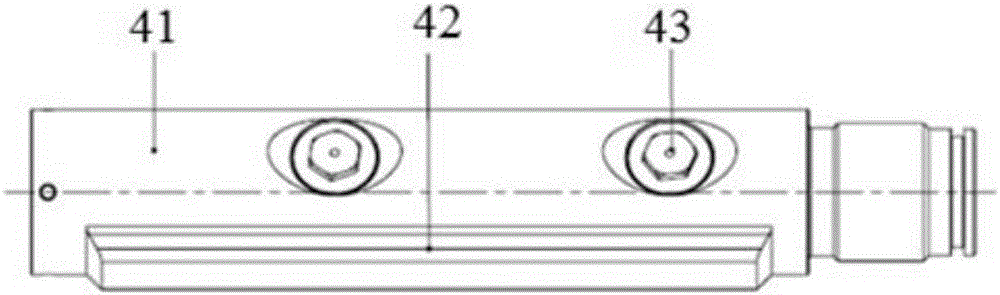

[0037] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, a horizontal well directional sandblasting perforating and fracturing integrated tool string includes a safety joint 1, a first centralizer 2, a first rotary joint 3, a hydraulic sandblaster 4, a second rotary joint 5, and a The second centralizer 6, the packer 7, the coupling locator 8, and the shoe guide 9, the safety joint 1, the first centralizer 2, the first rotary joint 3, the hydraulic sandblaster 4, the second rotary joint 5, and the second The centralizer 6, the packer 7, the coupling locator 8 and the shoe guide 9 are all horizontally and coaxially arranged in the casing. The safety joint 1 is arranged at the left end of the tool string, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com