Reinforcing mesh dropping device

A technology of steel mesh and bottom frame, applied in the field of machinery and equipment, can solve the problems of high work intensity, low work efficiency, unfavorable automatic production of cement prefabricated panels, etc., so as to reduce labor intensity, improve production efficiency, and improve economic benefits and social effect of benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

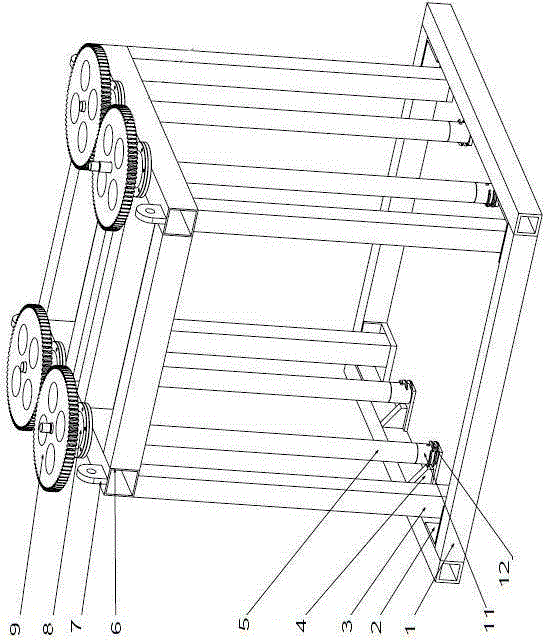

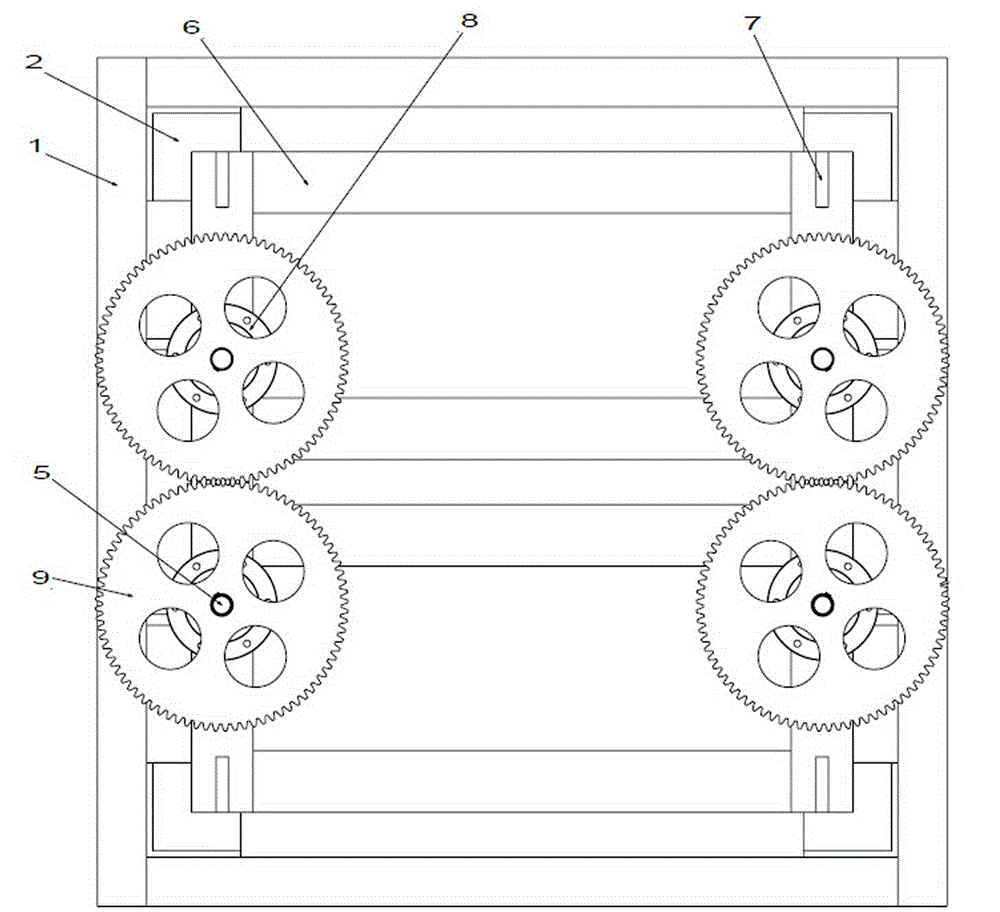

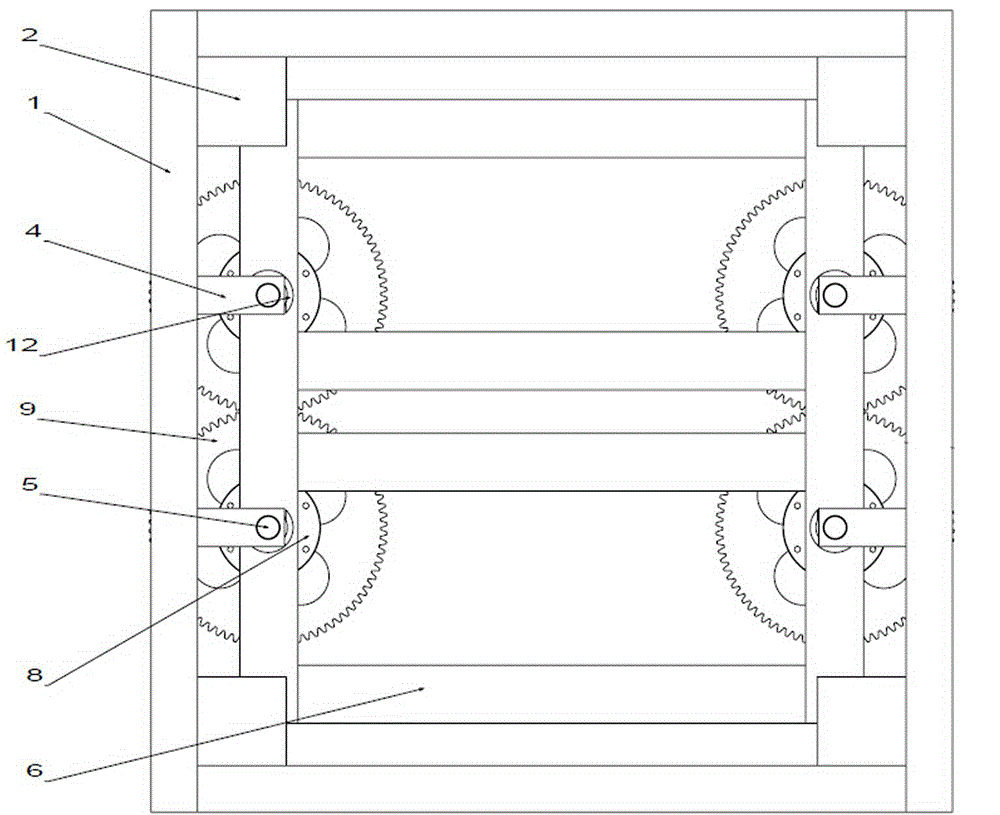

[0023] Embodiment 1: as Figure 1-6 Shown, a kind of steel net falling device comprises bottom frame 1 and upper frame 6, and hanging pan 7 is installed on upper frame 6, and hanging pan can hoist the whole device.

[0024] The corners inside the bottom frame 1 are respectively welded with supporting plates 2 , the lower ends of the columns 3 are installed on the supporting plates 2 , and the upper ends of the columns 3 are connected with the upper frame 6 .

[0025] Two supports 4 are respectively welded inside the two opposite sides of the bottom frame 1, and each support 4 is equipped with a rotating shaft 5, and the lower part of the rotating shaft 5 is provided with a clamping device, and the clamping device includes a sleeve 11. The sleeve 11 is sleeved on the lower end of the rotating shaft 5, and can be rotated synchronously with the rotating shaft 5 tightly, and the sleeve 11 is provided with four layers of claws 12, and the four layers of claws 12 are on the half sid...

Embodiment 2

[0030] Embodiment 2: A kind of steel mesh falling device, comprising a bottom frame and an upper frame, the bottom frame and the upper frame are connected by columns, at least two supports are welded inside the bottom frame, and a rotating shaft is installed on each support, and the rotating shaft The lower part is provided with a clamping device, the upper end of the rotating shaft is provided with a rotating device, and a hanging pan is installed on the upper frame.

Embodiment 3

[0031] Embodiment 3: A device for dropping steel mesh, including a bottom frame and an upper frame, and support plates are respectively welded at the corners inside the bottom frame, the lower ends of the columns are installed on the support plates, and the upper ends of the columns are connected with the upper frame. The inside of the bottom frame is welded with at least two bearings, each bearing is equipped with a rotating shaft, the lower part of the rotating shaft is provided with a clamping device, the upper end of the rotating shaft is equipped with a rotating device, and a suspension plate is installed on the upper frame.

[0032] Wherein, the area of the bottom frame is larger than the area of the upper frame.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com