Baby milk brewing machine

A technology of baby milk powder and milk making machine, which is applied in beverage preparation devices, household appliances, applications, etc. It can solve the problems of milk powder agglomeration, unsatisfactory users, water vapor easily entering the powder box, etc., and achieve the effect of switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

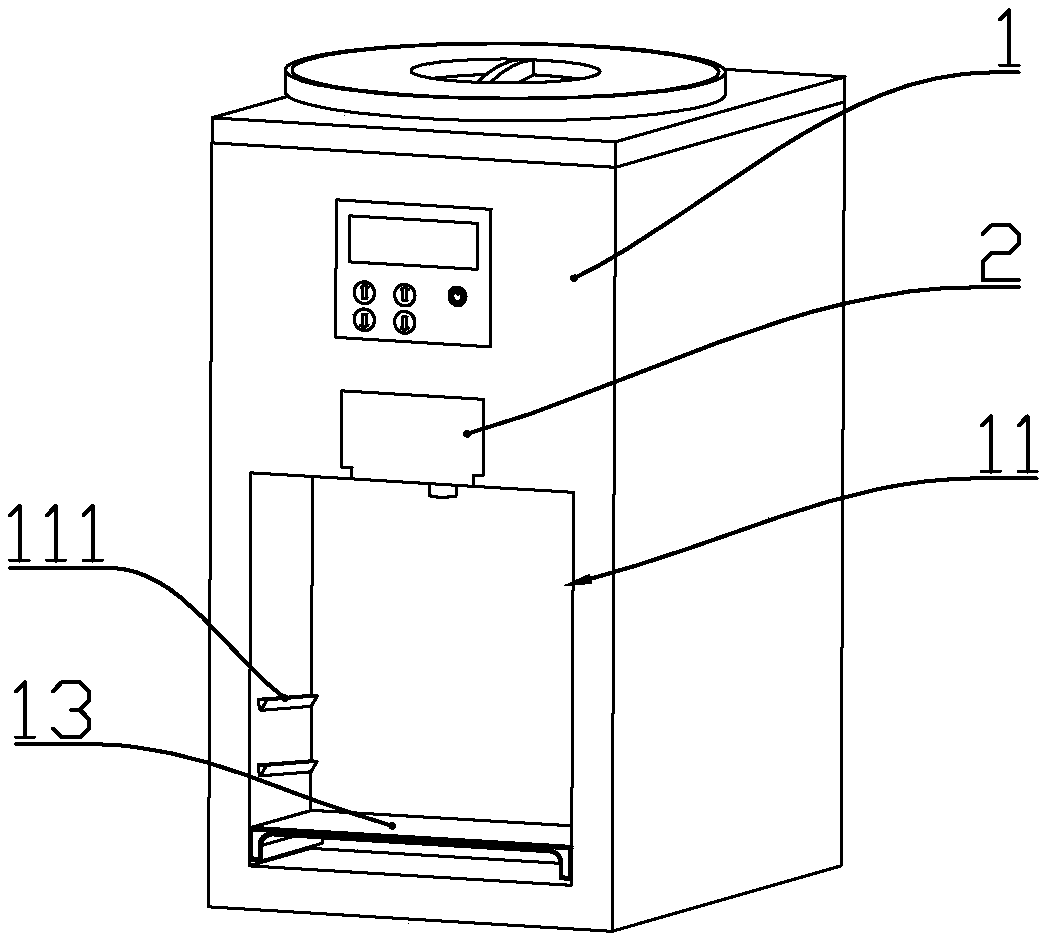

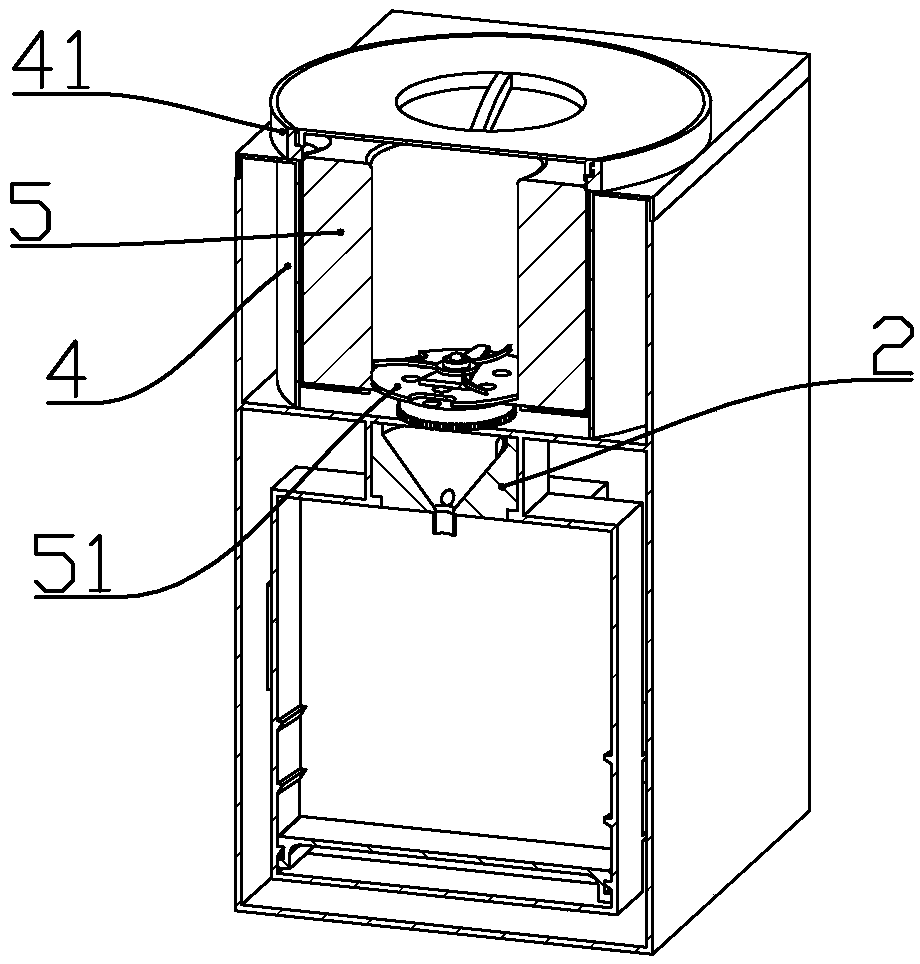

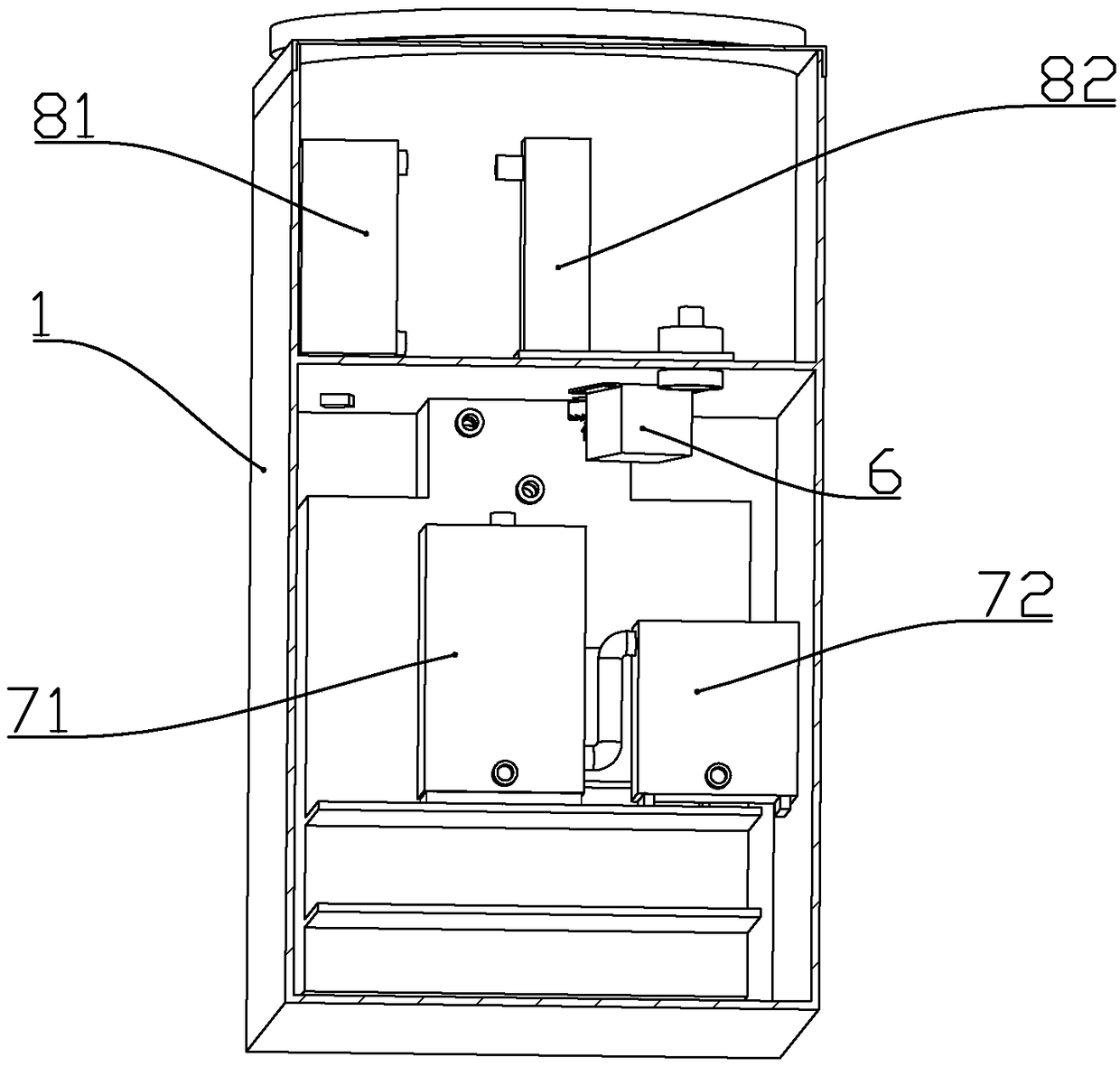

[0066] according to Figure 1 to Figure 25 As shown, a baby milk powder brewing machine described in this embodiment includes a housing 1; the housing includes a main body cavity 12, a feeding bottle placement cavity 11 located at the front end of the main cavity, and a cavity located at the upper end of the main cavity. Milk powder box assembly installation cavity 15.

[0067] A milk powder box assembly A for discharging milk powder is installed in the installation cavity of the milk powder box assembly; a water tank 31 is installed in the rear of the main body cavity.

[0068] The front end of the housing is located at the upper end of the feeding bottle placement cavity and a mixer installation cavity 14 is formed; a mixer 2 for mixing water and milk powder is installed in the mixer installation cavity; the top of the mixer installation cavity is formed to be useful In the cavity outlet 142 for milk powder to pass through.

[0069] The milk powder box assembly includes an...

Embodiment 2

[0151] according to Figure 26 As shown, this embodiment makes the following improvements on the basis of Embodiment 1: two sealing covers 401 are fixedly connected to the lower end of the discharge cover; the diameter of the sealing cover is larger than the diameter of the storage chamber; The sealing covers are respectively located at the upper ends of the non-working material storage chambers, and seal against the upper ends of the material storage chambers.

[0152] Because the two storage chambers that are not working are sealed against the sealing cover respectively, outside air cannot enter the storage chamber, so that the dryness in the storage chamber is kept, and the placement time of the milk powder is prolonged.

Embodiment 3

[0154] according to Figure 27 As shown, the difference between this embodiment and the preceding embodiments is that: the heating water tank is communicated with the mixer through a hose 93; the cold water tank is also communicated with the mixer through a hose.

[0155] Two rotating electromagnets 91 respectively used to control the water flow in the hose are installed in the installation cavity of the milk powder box assembly; Attach the eccentric wheel 911 to realize the cut-off.

[0156] An electromagnet mounting seat 92 is fixedly connected to the mounting cavity of the milk powder box assembly; the rotating electromagnet is fixedly connected to the electromagnet mounting seat; Pipe fixing seat 921; the hose is clamped in the hose fixing seat.

[0157] By controlling the rotating electromagnet to drive the eccentric wheel to work, the hose is cut off or circulated, and then the amount of hot water and cold water flowing out is controlled, so that the outflowing hot wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com