Ship anti-pollution method

An anti-fouling and ship technology, applied in the field of ships, can solve the problems of genetic variation of aquatic animals, destroying the ecological balance of the marine environment, and death of seaweed, etc., and achieves the effects of excellent adhesion, easy to apply multiple times, and strong adhesion ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

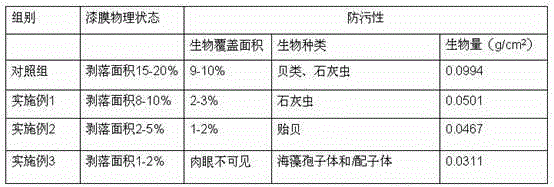

Examples

Embodiment 1

[0024] A ship antifouling method, comprising the steps of:

[0025] (1) Steel plate surface pretreatment: use shot blasting line for pretreatment to remove oil, water and sundries on the surface.

[0026] (2) Sandblasting treatment of the substrate: sandblasting the substrate to the Sa2.5 standard. During this process, the compressed air pressure is 0.5-0.6MPa, the diameter of the steel shot is 1.2-1.5mm, and the hardness of the steel shot is HV400-500. Nozzle diameter 4-6mm.

[0027] (3) Sandblasting for repairing structural defects such as welds: the surface to be coated is sandblasted to Sa2?, with a roughness > 80 microns; the abrasive is steel grit,

[0028] Copper ore; the maximum allowable salt value is 240μs / cm; the dust distribution level of the surface dust particle size is "3", "4" and "5". When spraying, the spray gun is kept perpendicular to the surface to be coated, and the distance is 200 ~ 280mm.

[0029] (4) Applying the primer: Use compressed air to remove...

Embodiment 2

[0037] Operation steps are identical with embodiment 1, difference is,

[0038] In step 4, the raw material formula of the primer is: 35 parts of solid acrylic acid, 20 parts of furfuryl alcohol modified urea-formaldehyde resin, 5 parts of molybdenum red, 12 parts of mica powder, 3 parts of organic acid ammonia complex, 6 parts of auxiliary agent and 15 parts of deionized water.

Embodiment 3

[0040] The operation steps are the same as in Example 1, except that in step 6, the topcoat includes the following raw materials in parts by weight: 35 parts of fluorinated acrylate, 30 parts of silicone rubber, 22 parts of polyethylene powder, 1 part of organic bentonite 1 part, polyethylene wax 1 part, propylene glycol 4 parts, capsaicin 1 part, tannic acid 1 part, diterpene formamide 1 part, P-cinnamic acid sulfate 1 part, lobster creatinine 1 part.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com