Method for producing titanium alloy artware by adopting selective laser melting

A technology of selective laser melting and laser melting, applied in the direction of improving process efficiency, improving energy efficiency, etc., can solve the problems of low density, poor finish, difficult to process patterns and graphics, and achieve stable forming quality and forming process. , the effect of great artistic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

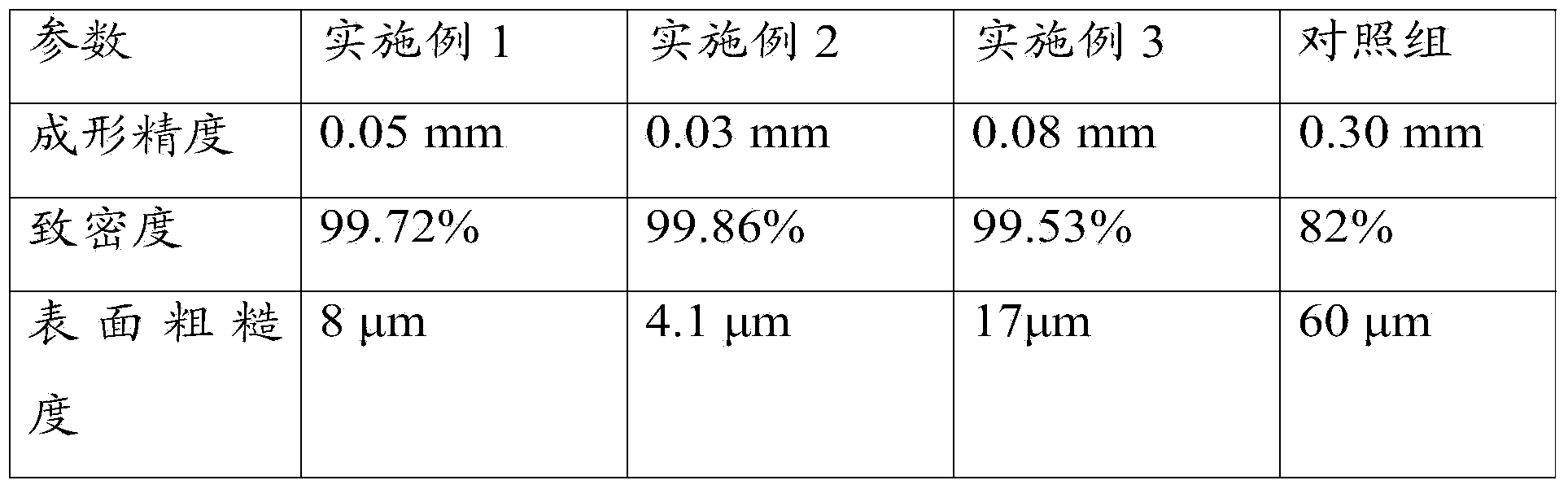

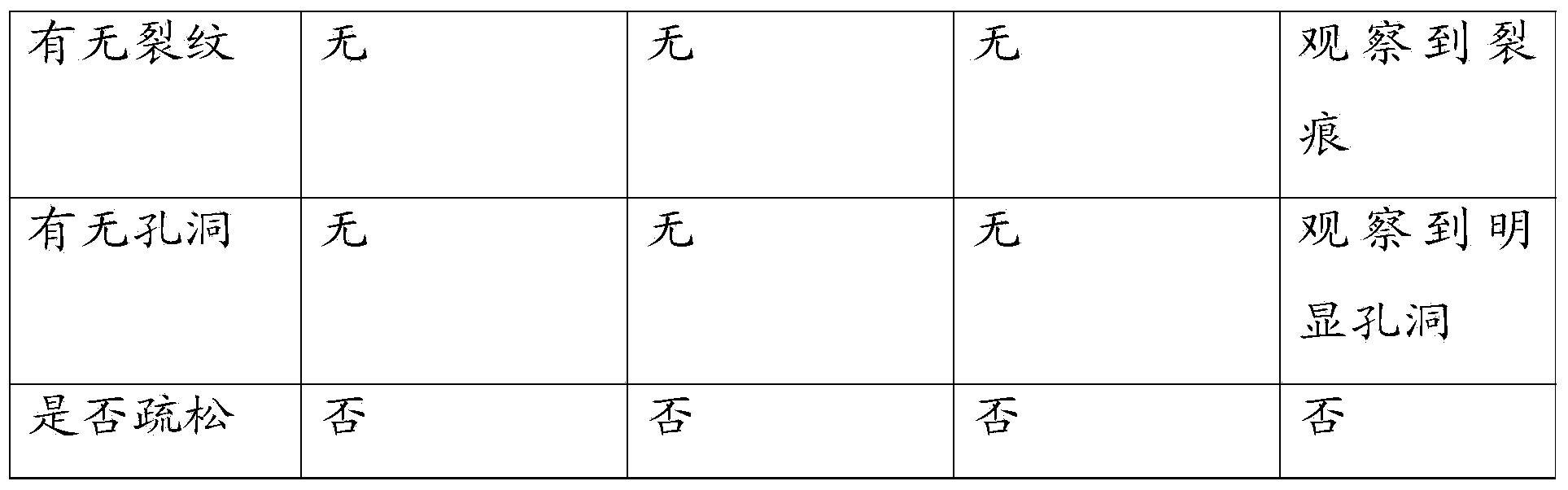

Examples

Embodiment 1

[0048] Import the two-dimensional images of the head portrait of the person and the dragon totem into the two-dimensional image processing software for processing. The head portrait of the person will generate a three-dimensional entity with a relief effect, and the totem of the dragon will generate a three-dimensional image with a hollow effect; import the generated three-dimensional image into the three-dimensional software for handicrafts The overall design forms a craft gift plate model with character reliefs and dragon totem hollow patterns; export the gift plate model as an STL format file and import it into the special editing software for 3D printing to design supports, and perform two-dimensional analysis on the designed support 3D model process to obtain the SLI two-dimensional slice data file;

[0049] Import the SLI two-dimensional slicing data file into the metal powder laser melting system as a data instruction for selective laser melting, ready for laser melting ...

Embodiment 2

[0060] Import the two-dimensional images of the animal head and the dragon totem into the two-dimensional image processing software for processing, the animal head generates a three-dimensional entity with a relief effect, and the dragon totem generates a three-dimensional image with a hollow effect; import the generated three-dimensional image into the three-dimensional software for handicrafts The overall design forms a craft gift plate model with animal relief and dragon totem hollow patterns; export the gift plate model as an STL format file and import it into the special editing software for 3D printing to design the support, and perform two-dimensional analysis on the designed support 3D model process to obtain the SLI two-dimensional slice data file;

[0061] Import the SLI two-dimensional slicing data file into the metal powder laser melting system as a data instruction for selective laser melting, ready for laser melting forming;

[0062] Set the processing parameters...

Embodiment 3

[0072]Import the cartoon image and the two-dimensional image of the dragon totem into the two-dimensional image processing software for processing. The cartoon image generates a three-dimensional entity with a relief effect, and the dragon totem generates a three-dimensional image with a hollow effect; import the generated three-dimensional image into the three-dimensional software for handicrafts The overall design forms a craft gift plate model with cartoon relief and dragon totem hollow patterns; export the gift plate model as an STL format file and import it into the special editing software for 3D printing to design the support, and perform two-dimensional analysis on the designed support 3D model process to obtain the SLI two-dimensional slice data file;

[0073] Import the SLI two-dimensional slicing data file into the metal powder laser melting system as a data instruction for selective laser melting, ready for laser melting forming;

[0074] Set the processing paramet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size distribution | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com