Anti-back-splash sand blasting perforator

A technology of sand blasting perforation and nozzles, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., which can solve the problem of increasing the difficulty and cost of manufacturing perforators, increasing the number of joint gaps between components, and increasing the number of spray holes. Sealing difficulties and other issues, to achieve the effect of easy processing and assembly, reduce erosion, and improve convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

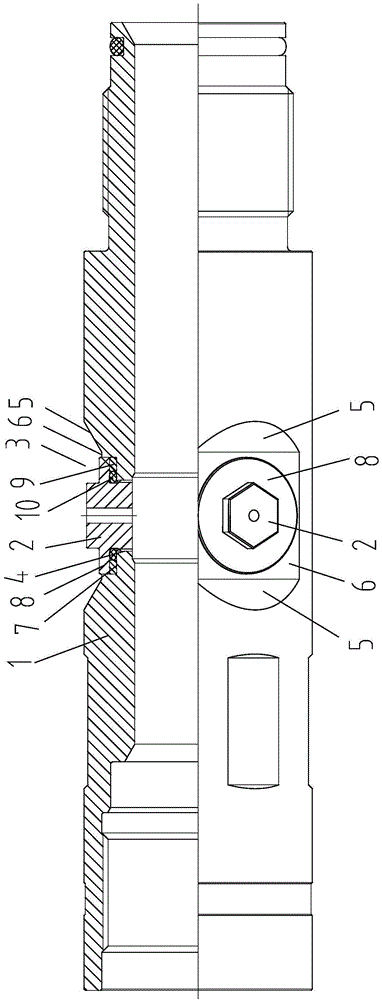

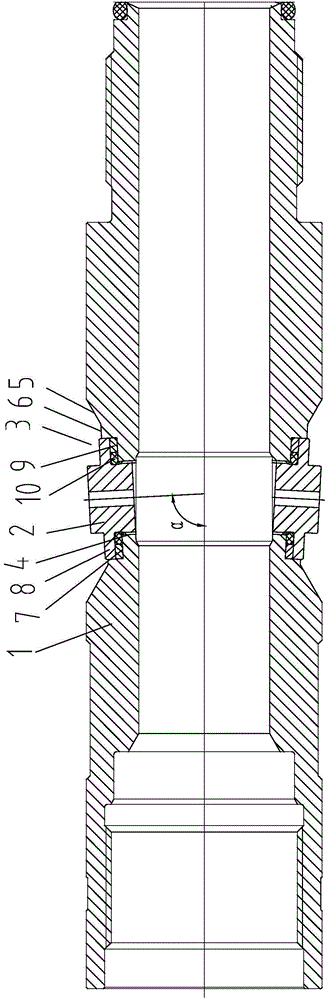

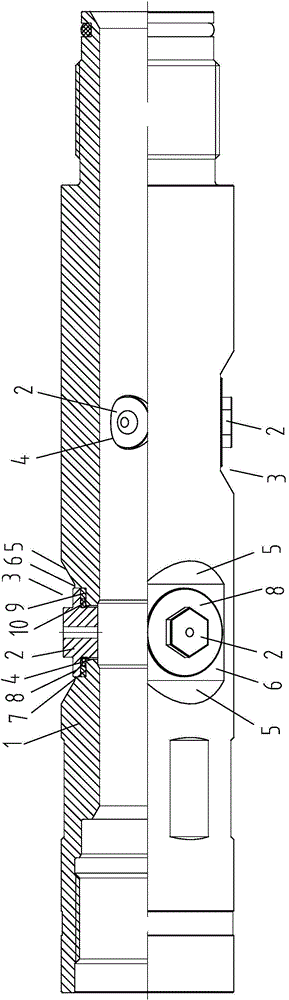

[0027] Anti-backsplash sandblasting perforator of the present invention, such as Figures 1 to 3 As shown, a body 1 and a nozzle 2 are included, and a plurality of nozzles 2 can be provided.

[0028] The outer wall of the body 1 is provided with a groove 3 , and the middle part of the groove 3 is provided with an installation hole 4 , and the nozzles 2 are installed in the installation hole 4 corresponding to the groove 3 .

[0029] The side wall 5 of the groove 3 is inclined, and the distance between it and the bottom surface 6 is 120°~160°. The outer end of the nozzle 2 protrudes from the bottom surface 6 of the groove 3, so that the side wall of the outer end of the nozzle 2 and the bottom surface 6 of the groove 3 and the side wall 5 of the groove 3 form a guide structure. The surface of the groove 3 and the surface of the body 1 on the edge of the groove 3 are provided with a wear-resistant coating, and the outer end of the nozzle 2 and the outer surface of the flange, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com