A Split Flange Connection Rotary Joint

A rotary joint and connection technology, which is applied in the direction of adjustable connection, pipe/pipe joint/fitting, passing components, etc., can solve the problems of difficulty in replacing the rotary joint, inaccurate positioning, jumping, etc., and achieve fast installation, maintenance and replacement, and diameter Accurate positioning, simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

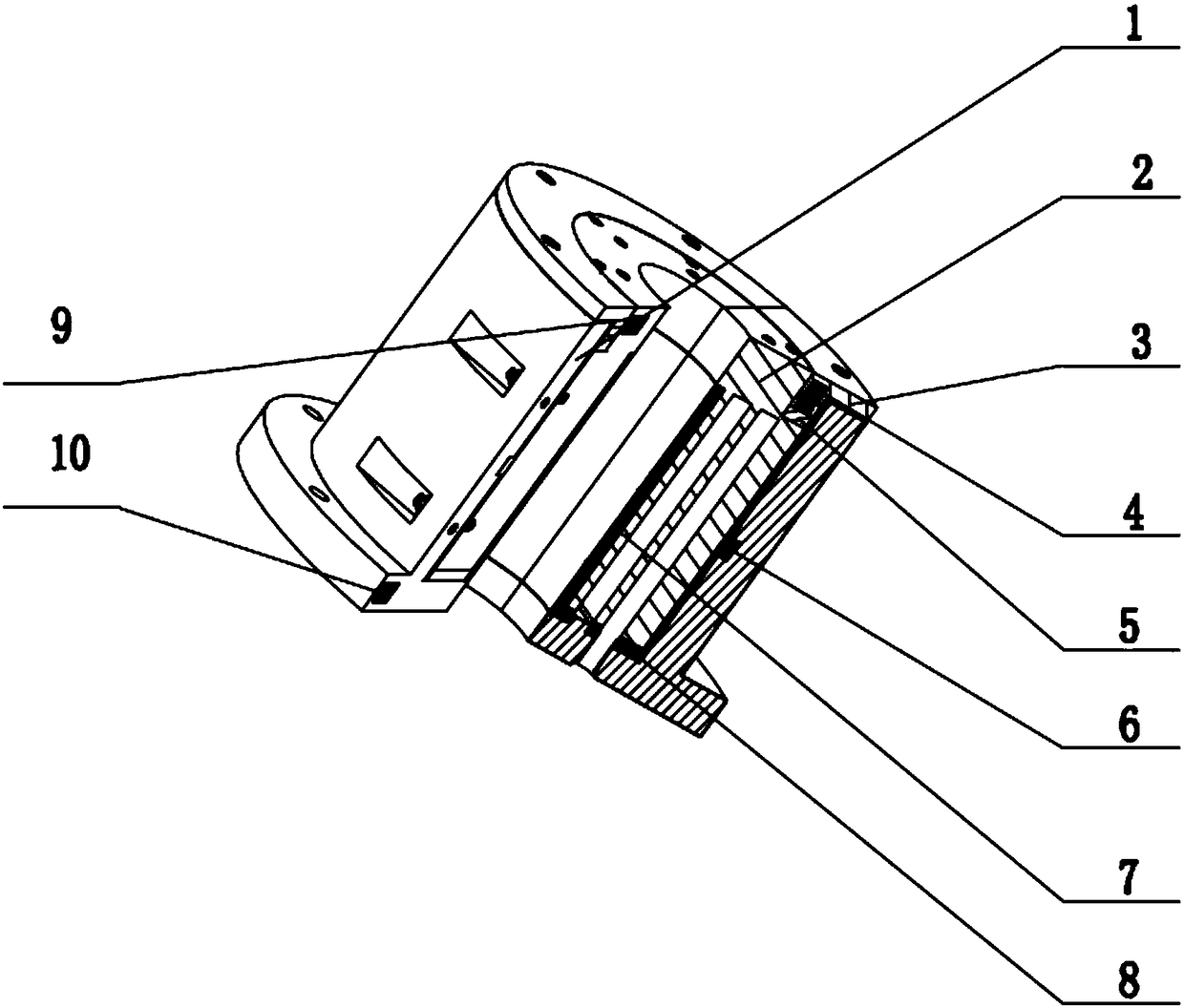

[0027] The following is attached Figure 1-14 The present invention is further described.

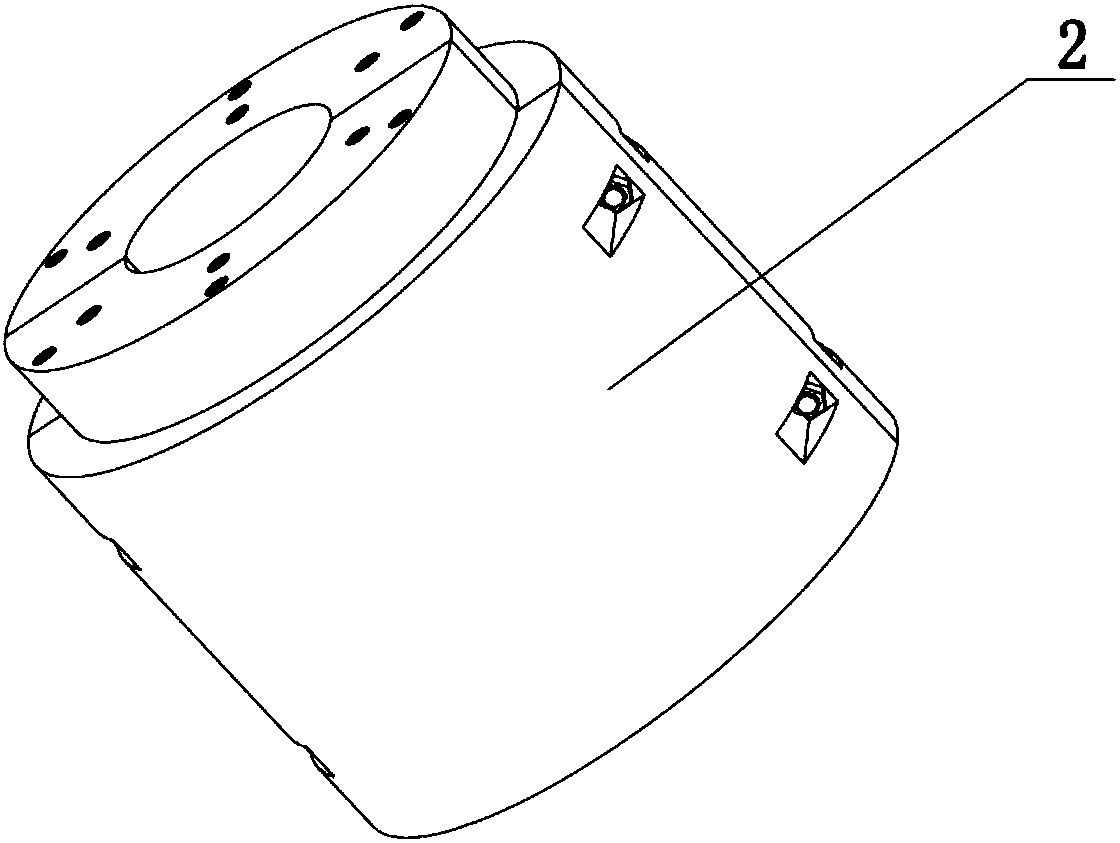

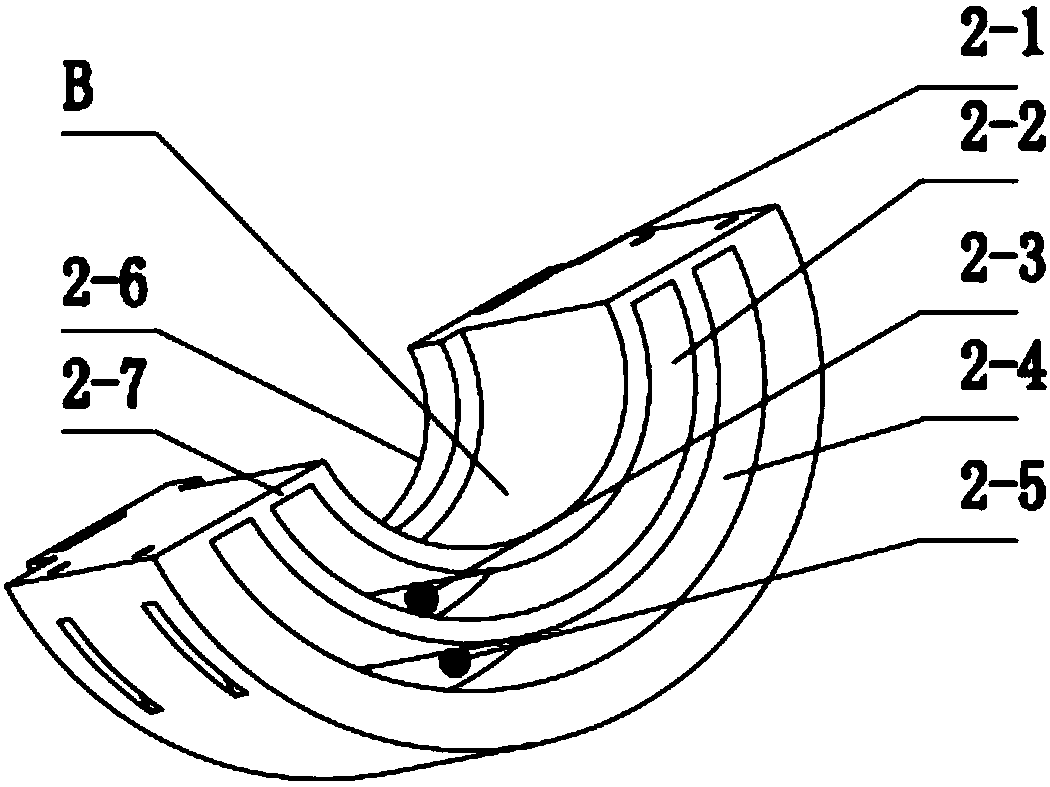

[0028] A split flange connection type rotary joint, which is composed of an assembled shell 1, a moving ring 2, an end cover 3, a spring 4, a spring pad 5, a bearing bush 6, a sealing material 7 and a semicircular sealing ring 8, and is characterized in that The shell 1 and the moving ring 2 are both split structures, the positioning block is positioned by its positioning groove, and its split surface is fixed into a whole through a bolt group. The end cover 3 is fixed on the shaft end of the split casing A, the split casing A and the bearing bush 6 are connected through the positioning ring groove 1-2 and the positioning protrusion 6-1, and the casing 1 is connected with the rotating shaft fixing part to form the static part of the rotary joint ; The moving ring 2 is fixedly connected with the rotating shaft 12 to form the rotating part of the rotary joint; the end cover 3, the spring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com