Device to coat metallic coating onto wafer

A metal coating and wafer technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as limiting productivity and achieve high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

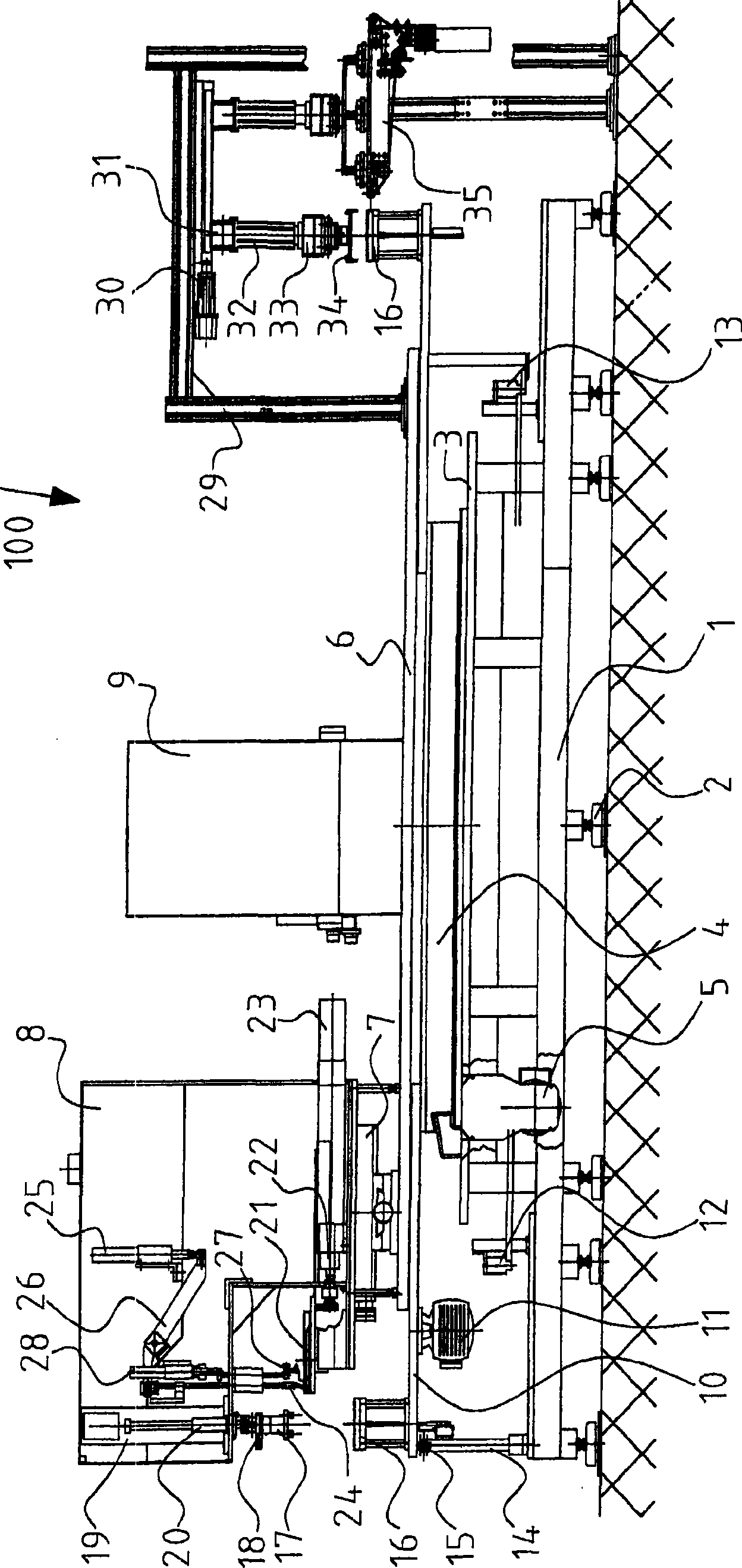

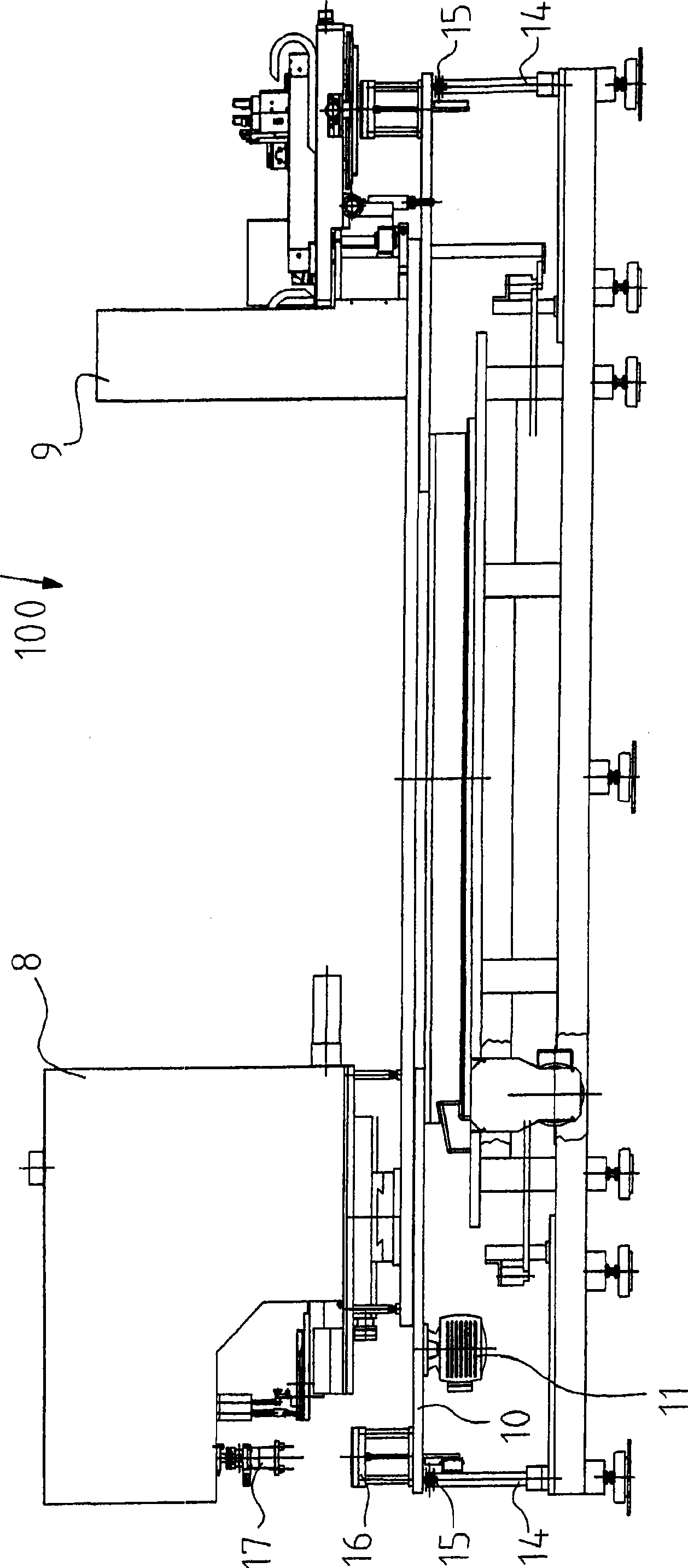

[0024] figure 1 A device 100 for applying a metal coating to wafers, not shown in detail, is shown. The device 100 has a base 1 which is supported on the ground by means of feet 2 . The feet 2 are adjustable so that the base 1 can be oriented horizontally. Arranged on the base 1 is a base plate 3 for a circular switch disk 4 , which can be rotated by means of a drive 5 in predetermined angular increments.

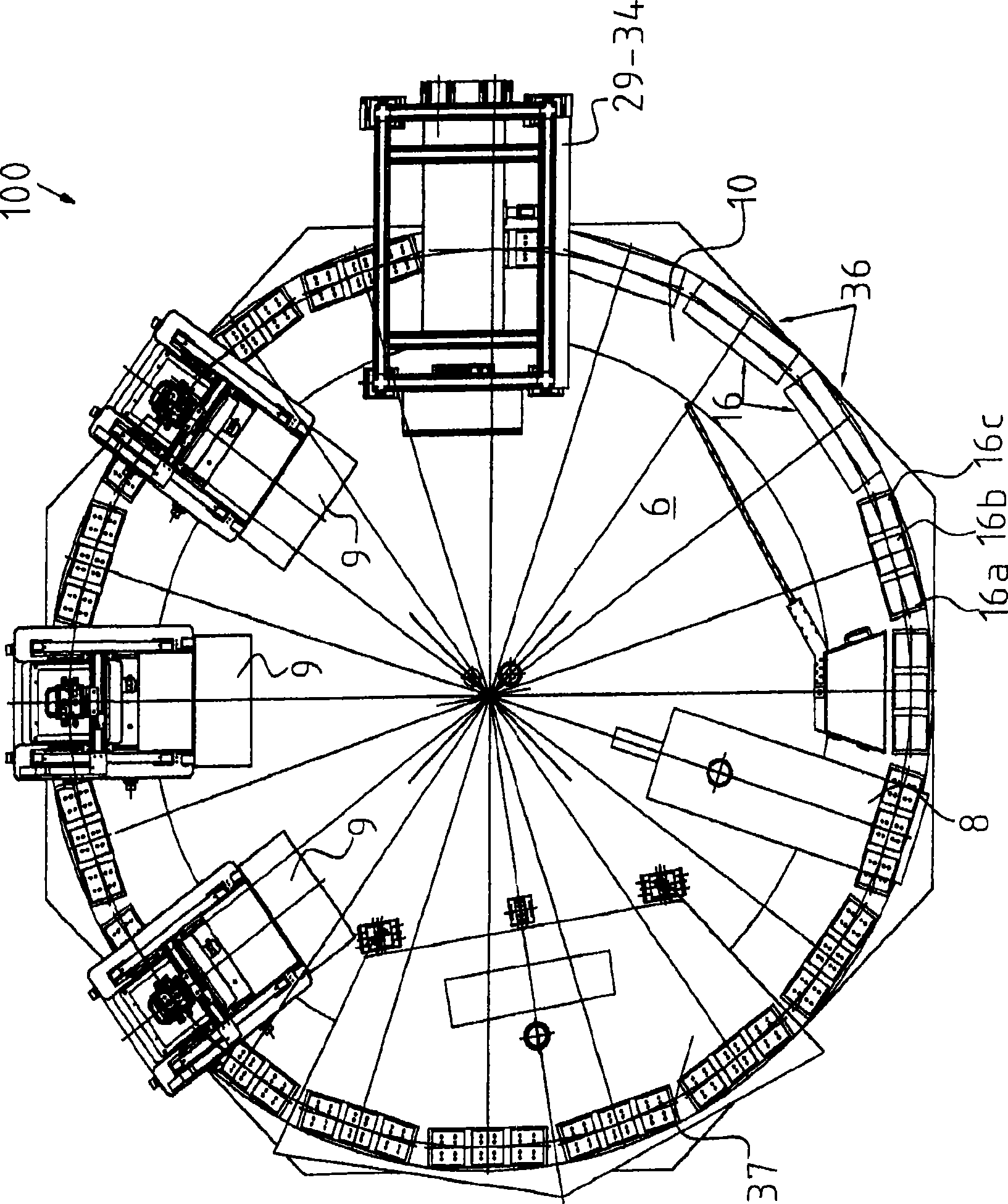

[0025] Furthermore, a base 6 is arranged on the base, on which a pad printing device 8 supported by an Oldham slide 7 is arranged. With the aid of the cross slide 7, the pad printing unit 8 can be positioned with very high precision. In addition, three screen printing devices 9 are arranged on the base 6. figure 1 and 2 Only one of the screen printing devices can be seen in each case. However, from image 3 See the layout of the three screen-printed setups.

[0026] The rotary table 10 is controlled to rotate around the base 6 by the drive device 5 . A plurality of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com