Method and system for operating two-and four-stroke engines using low sulfur fuels

a two-and-four-stroke engine and low sulfur fuel technology, which is applied in the direction of machines/engines, mechanical equipment, and organic compounds of the group 3/13 element, can solve the problems of deterioration of other lubricants used on-board vessels or at stationary sites, affecting and not going beyond certain limits without jeopardizing the condition of oiled engine components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

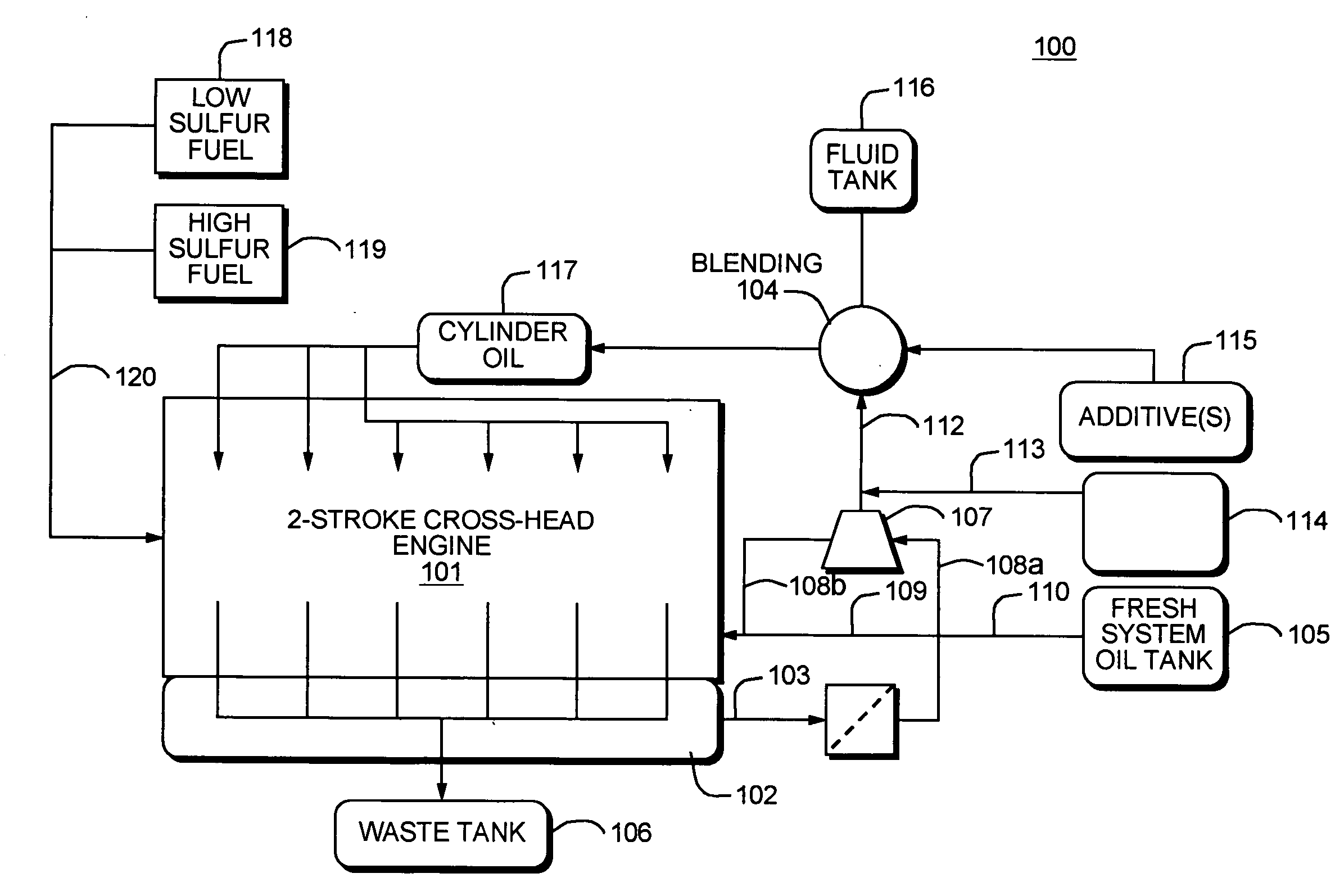

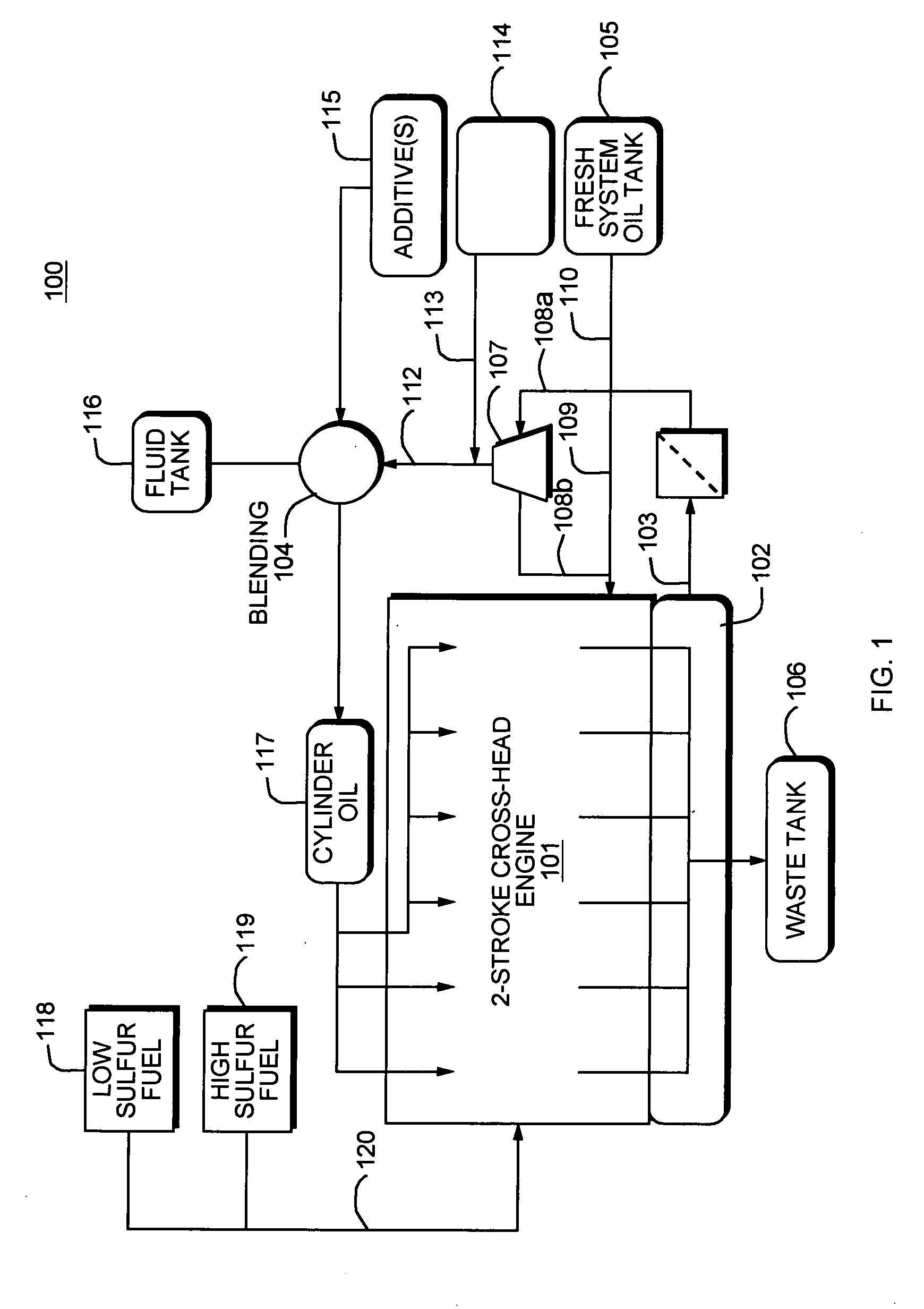

[0013]FIG. 1 shows a schematic representation of a system 100 including at least one two-stroke cross-head diesel engine 101. The engine 101 includes a first lubricating system containing system oil 102 and a second lubricating system includes an all-loss lubricant or cylinder oil 107. The system further includes used system oil conduit 103 and 109, system oil recycle loop 108a and 108b, waste tank 106, a fresh system oil tank 105, separator 107, transfer line 112, blending apparatus 104, additive tank 115, fluid storage tank 116, low sulfur-fuel tank 118, high sulfur fuel tank 119 and fuel line 120, for carrying out the method of the present invention. Fluid storage tank 116 may be used to store base oil, trunk piston engine oil, or used trunk piston engine oil.

[0014]According to an embodiment of the present invention, a two-stroke engine may be operated by supplying the blended cylinder oil and a fuel having sulfur content ranging from 1.0 wt. % sulfur to 0.001 wt. % sulfur to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| mole ratio | aaaaa | aaaaa |

| mole ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com