Detergent for synthetic calcium alkyl benzene sulfonate type lubricating oil and production technology

A technology of calcium alkylbenzene sulfonate and lubricating oil, applied in the petroleum industry, lubricating compositions, additives, etc., can solve problems such as undiscovered filter cake treatment methods, achieve the effect of reducing product cost and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] (1) Prepare a mixture of calcium oxide and neutral oil (hereinafter referred to as lime slurry)

[0068] Stir 70 grams of CaO (weight content greater than 93%, particle size: 325 mesh) and 90 grams of neutral oil (150SN) in a beaker at room temperature to disperse calcium oxide evenly in the neutral oil.

[0069] (2) Preparation of accelerator solution

[0070] Add 2 grams of anhydrous calcium chloride into a conical glass flask filled with 40 grams of industrial methanol, and shake it fully at room temperature to dissolve it completely.

[0071] (3) Add 155 grams of toluene, 52 grams of neutral oil, and 25 grams of 1 # , 75 g 2 # Synthesis of alkylbenzenesulfonic acid (1 # ,2 # The characteristics of sulfonic acid are: 1 #: Sulfonic acid content ≥ 85% and monoalkyl substituent ≥ 85%, average molecular weight Mn-420, alkyl substituent: C 20 -C 24 Straight-chain alkyl; 2 # : Sulfonic acid content: 60% and mainly dialkyl substitutes; average molecular...

Embodiment 2

[0089] In the present embodiment, in addition to washing the filtrate of the filter cake once with 161 grams of toluene in Example 1 instead of the actual

[0090] Except the toluene in embodiment 1, all the other are identical with embodiment 1.

[0091] Result: hot press filtration time: 3min, filtrate weight: 366g, yield: 95%

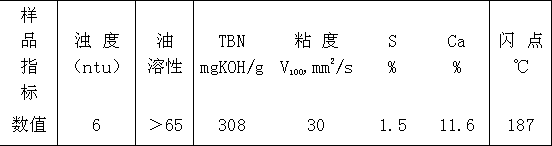

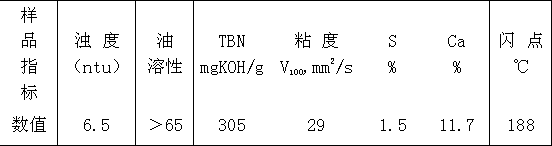

[0092] The sample characteristic parameters are as follows:

[0093]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com