Vibrating wire sensor using spectral analysis

A spectrum, vibrating wire instrument technology, applied in the field of sensors, can solve problems such as inability to distinguish string resonance from external noise sources, errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

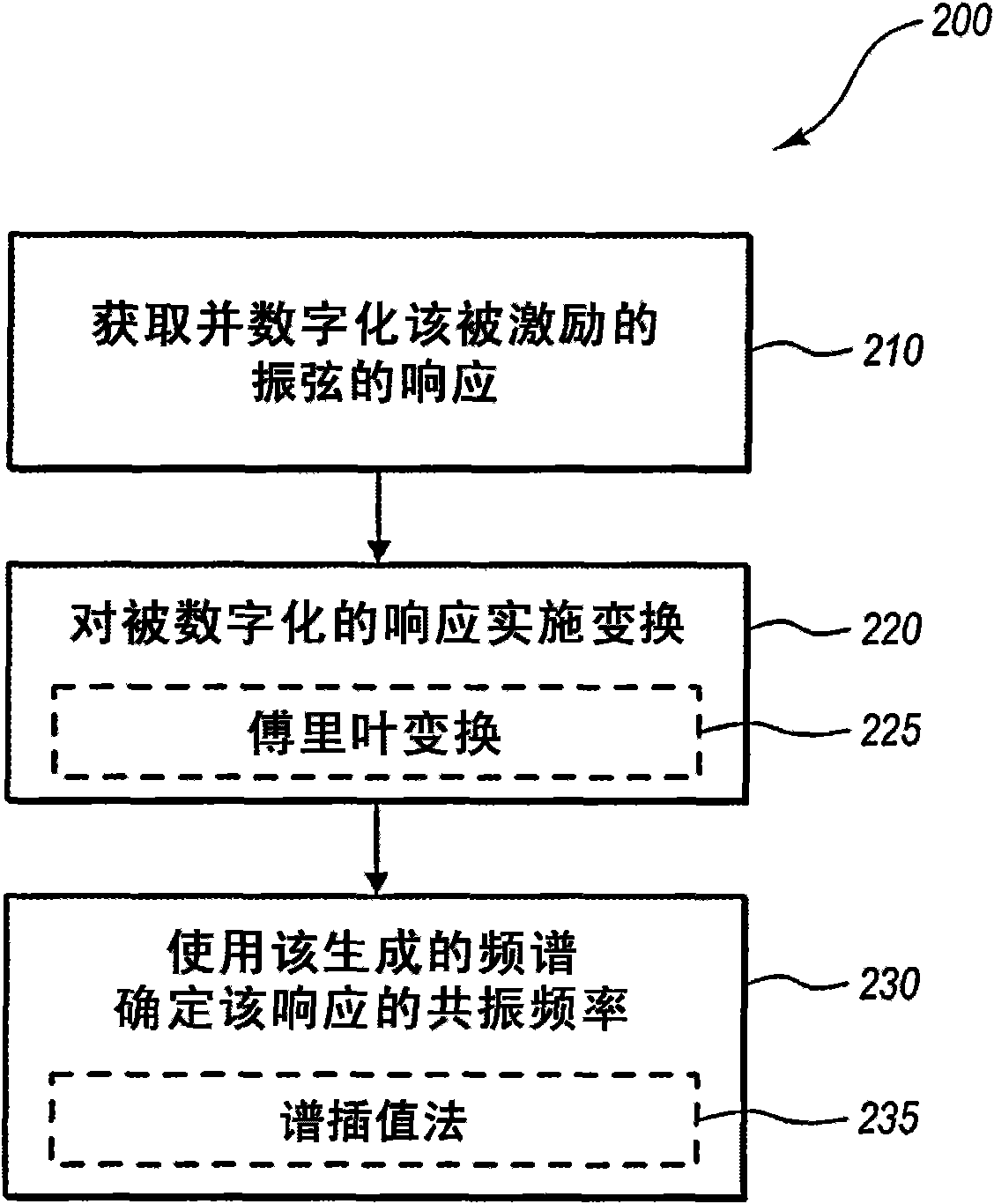

[0028] Embodiments of the invention relate to vibrating wire instruments and methods of determining the resonant frequency of the vibrating wire using spectral analysis. As briefly described above, the present invention is suitable for use in connection with vibrating wire instruments. More specifically, the invention is applicable to the conversion of raw responses collected by a vibratory gauge mechanism into digitized data, and the conversion of the digitized data into an accurate estimate of the resonant frequency of the vibrating wire. As previously mentioned, the resonant frequency of the vibrating wire can be used to calculate or estimate any number of properties, including but not limited to strain, stress, load, deflection, gas pressure, fluid pressure, displacement, liquid level, angular rotation, temperature , wind speed, fluid flow, precipitation, snow water equivalent, etc. or any combination thereof.

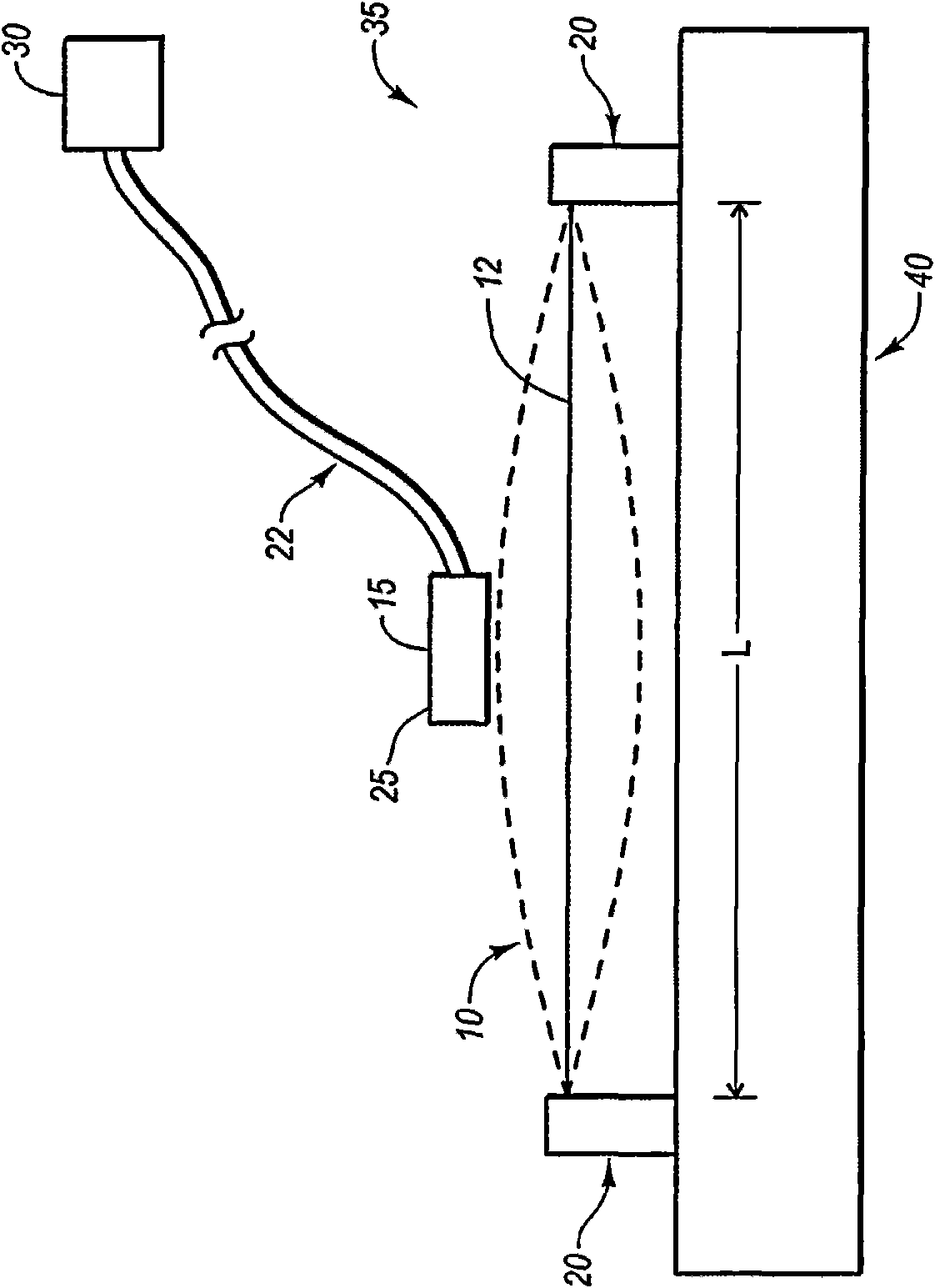

[0029] figure 1 A schematic diagram of one embodiment of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com