Automatic inserting-drawing mechanism for memory chip of mainboard function testing device

A technology of functional testing and automatic plugging and unplugging, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as low efficiency and low degree of automation, and achieve the effect of ensuring travel safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

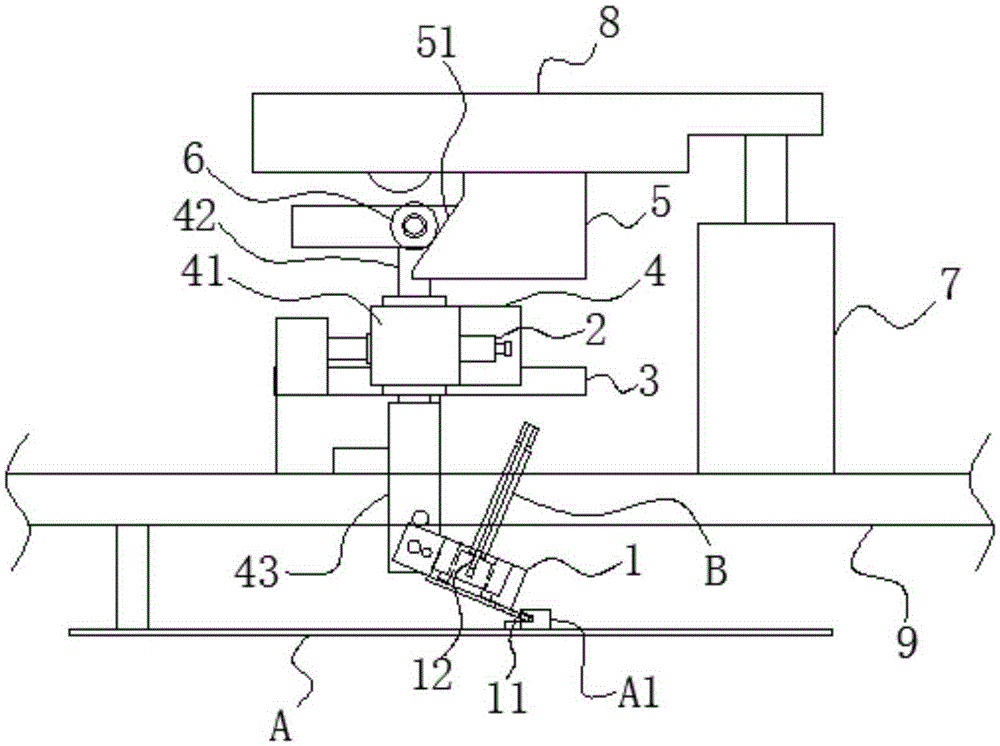

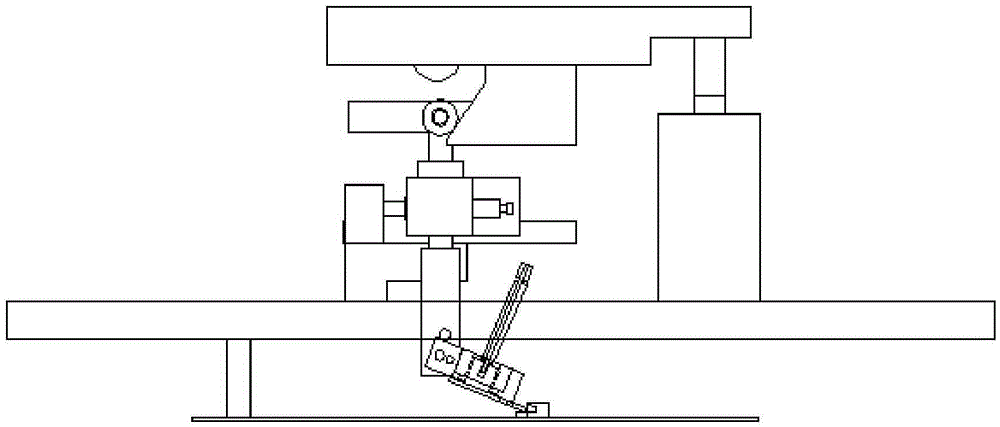

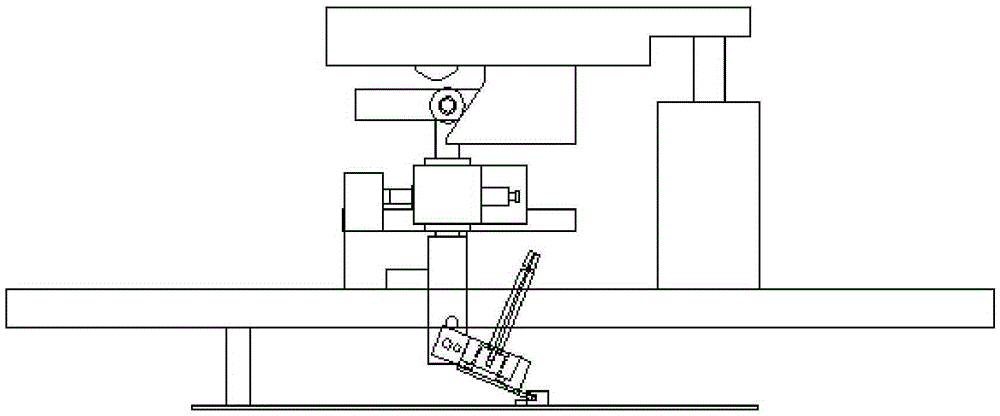

[0031] Embodiment: a memory stick automatic plug-in mechanism of a motherboard function test equipment, such as figure 1 with Figure 5 As shown, it includes an adapter plate 1, a spring PIN2, a guide wire gauge 3, a connection block 4, a guide block 5, a guide roller 6 and a power unit, and the power unit includes a lower pressure cylinder 7 and a lower pressure plate 8, and the lower The pressing plate 8 is fixed on the lower pressing cylinder 7, the guide block 5 is fixed on the bottom surface of the lower pressing plate 8, the spring PIN2 is fixed horizontally, the guide wire gauge 3 is fixed horizontally, and the connecting block 4 is fixed on the bottom surface of the lower pressing plate 8. The spring PIN2, the connecting block 4 can move forward and backward along the guide wire gauge 3, the upper end of the connecting block 4 is connected with a rolling bearing 6 and the lower end is connected with an adapter plate 1, the guide block has an inclined surface 51, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com