Air blowout structure and air blowout unit for air-floating conveyor apparatus, and air-floating conveyor apparatus having the same

A conveying device and air suspension technology, applied in the direction of conveyor objects, conveyors, transportation and packaging, etc., can solve the problems of difficult maintenance operations of the upper wall part 103, decreased positioning accuracy of the substrate, and inability to increase the acceleration and deceleration speed, etc., to achieve maintenance Ease of operation, increased acceleration and deceleration, and shortened conveying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

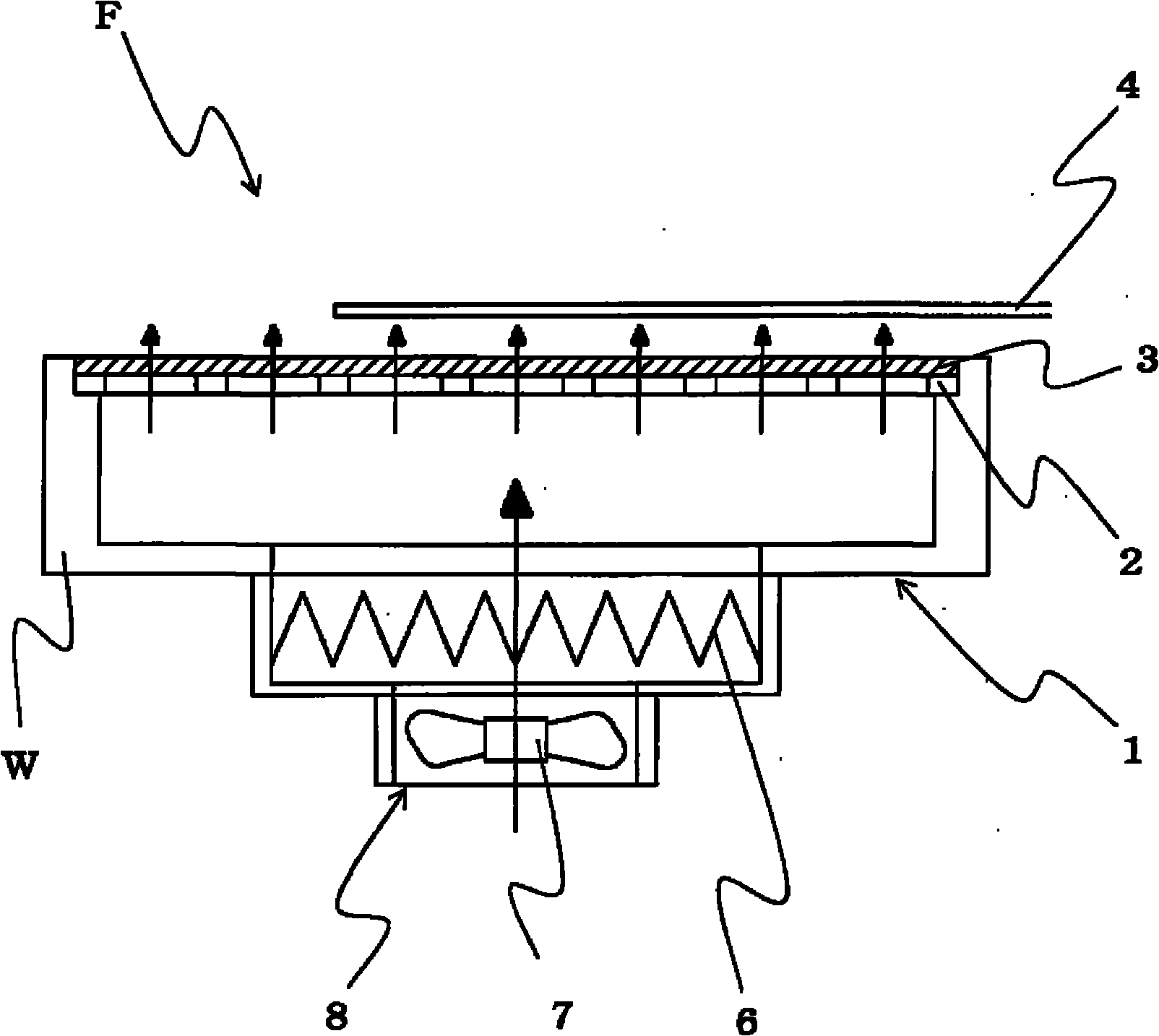

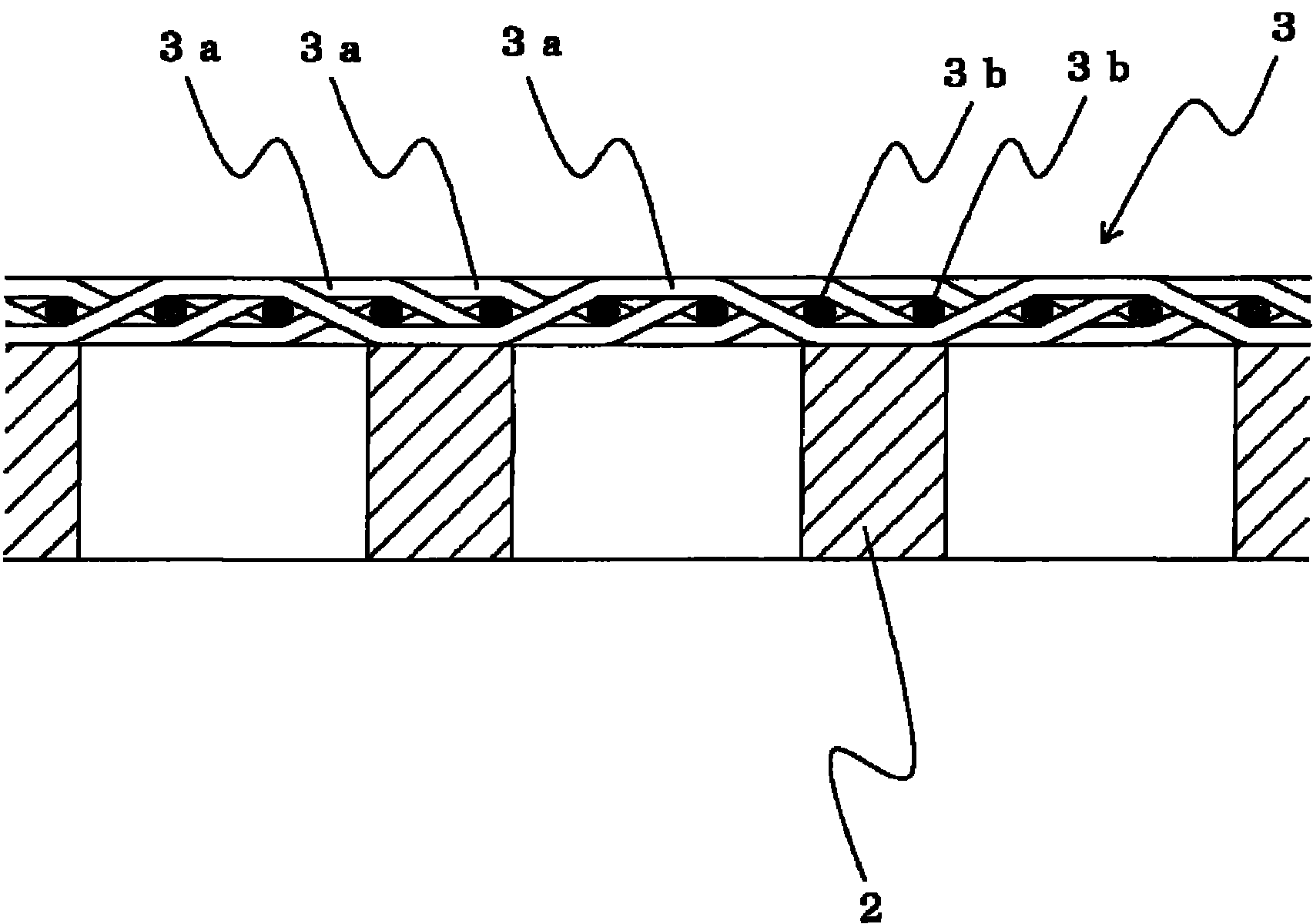

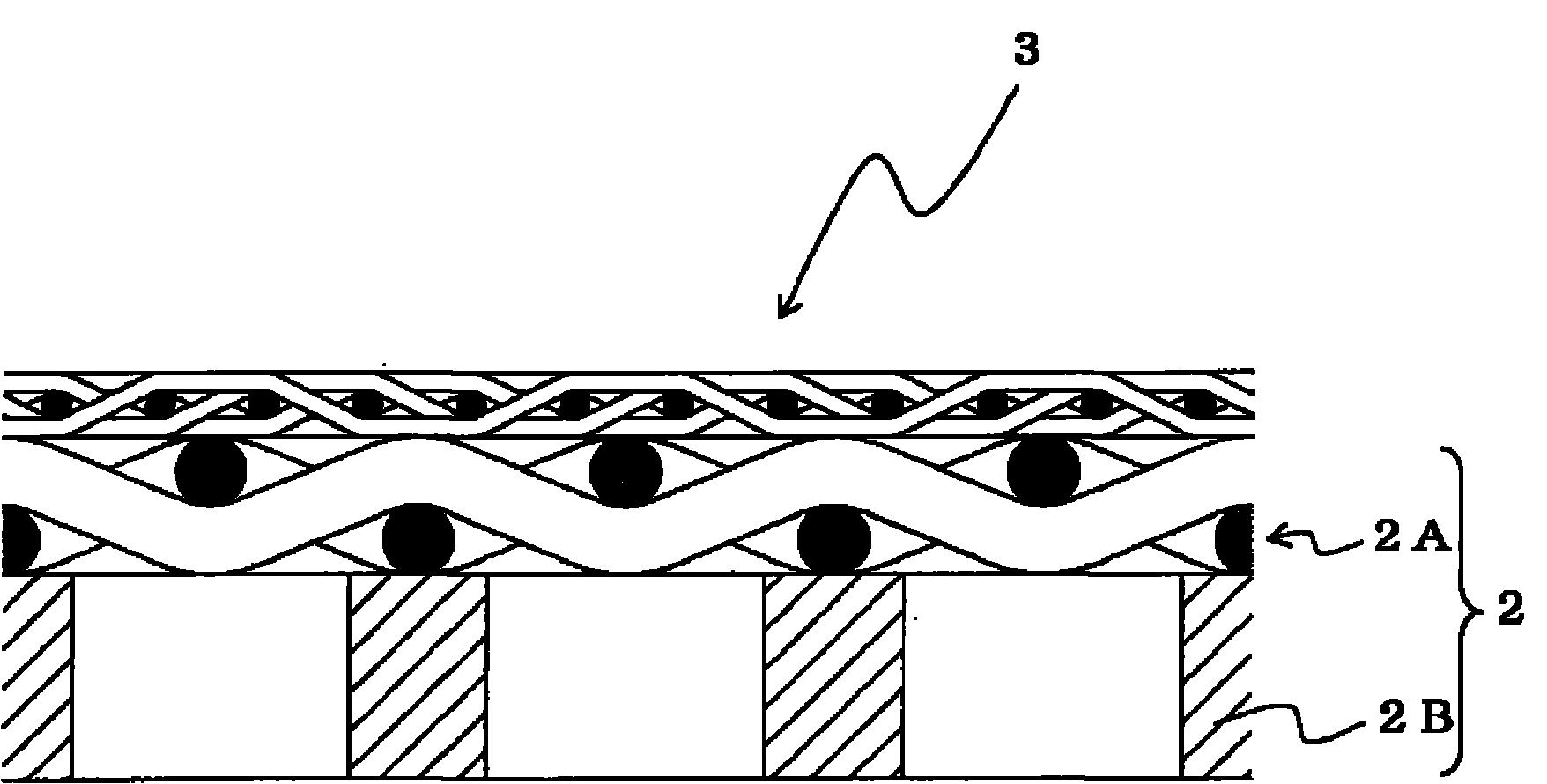

[0038] The air blowing structure of the air levitation conveying device of the present invention can be applied to an air levitating conveying device that suspends a sheet with air and conveys it with conveying rollers. The reinforcing member having a porosity arranged at the lower part of the woven wire mesh is constituted.

[0039] Here, the meaning of the terms used in the present invention will be described. In the present invention, the so-called air levitation conveying device includes a device that has a unit that levitates and supports a large and very thin glass substrate used in a flat panel display such as a liquid crystal display panel or a plasma display panel in a non-contact manner, or has the above-mentioned unit and conveying device using conveying rollers.

[0040] The air blowing structure refers to a porous structure capable of supplying air under pressure in the chamber of the air blowing unit to the upper surface portion of the unit (the lower surface si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com