Emergency braking device of elevator

An emergency braking and elevator technology, applied in transportation, packaging, elevators, etc., can solve the problems of loss of shock absorption, inability to exert elastic characteristics, lack of reproducibility of buffer body, etc., and achieve the effect of restraining height, reducing depth and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

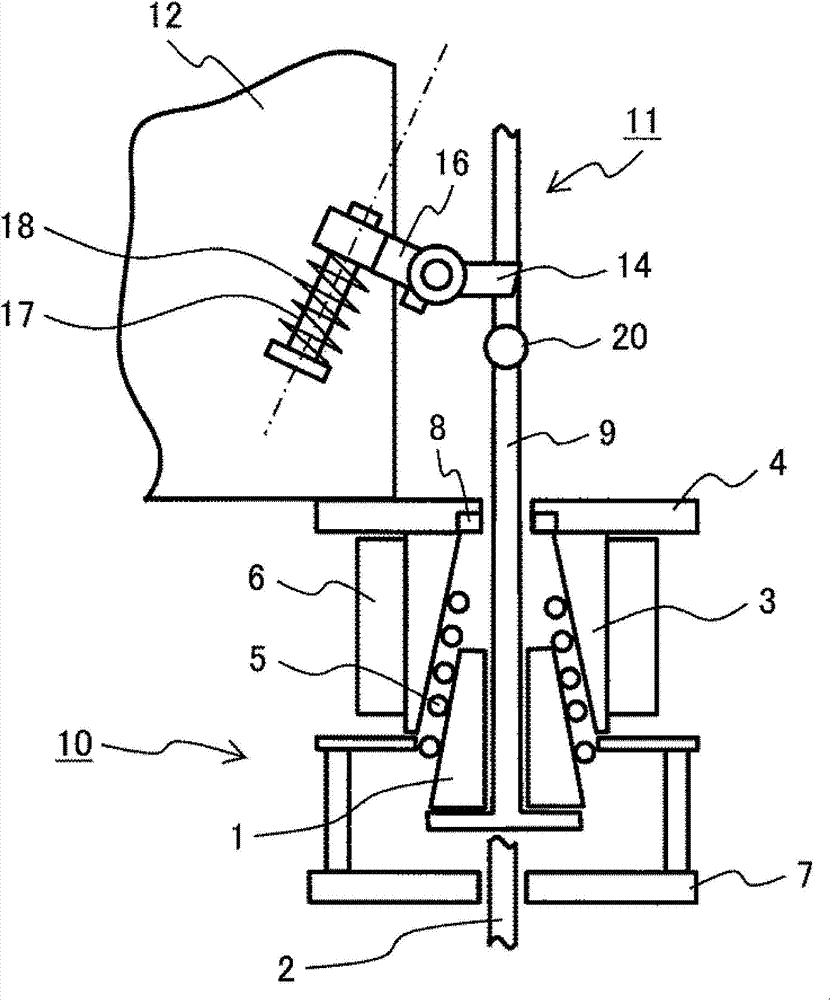

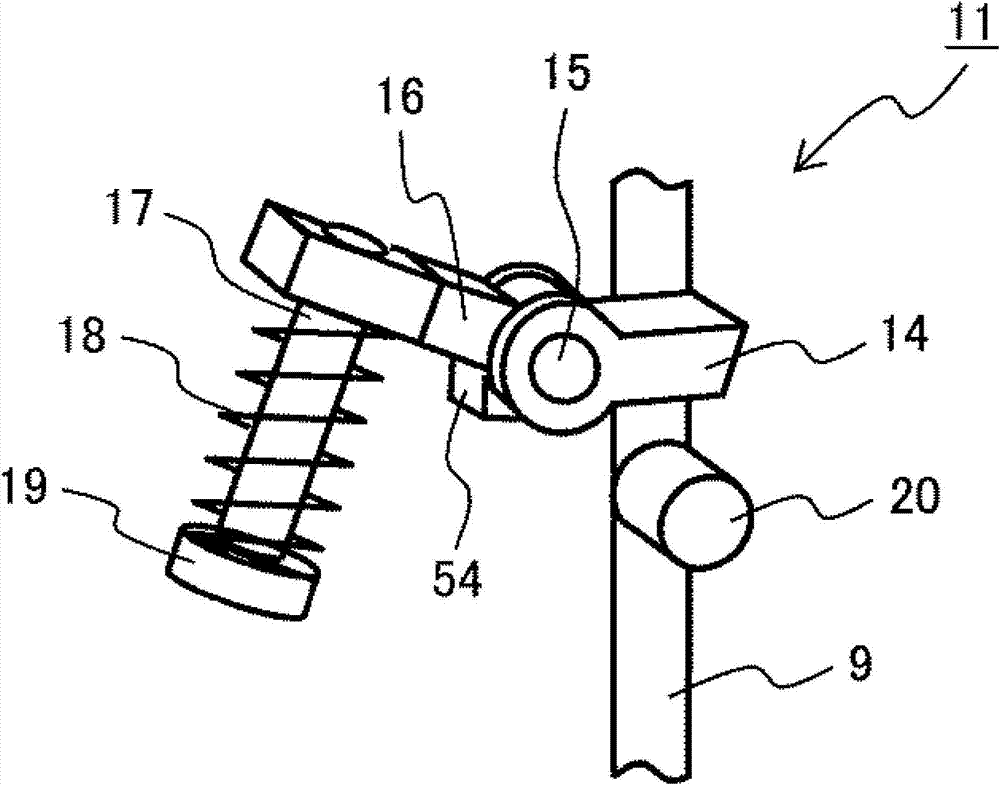

[0065] figure 1 is a schematic diagram of the emergency braking device according to the first embodiment of the present invention. The emergency braking device 10 is configured to have a left-right symmetrical structure with respect to the guide rail 2 . The pair of stoppers 1 are arranged substantially parallel to the guide rail 2 so as to clamp the guide rail 2 , and there is a slight gap between the pair of stoppers 1 and the guide rail 2 . The back surface of the braking member 1 is a smooth inclined surface in the shape of a wedge that narrows at the top.

[0066] The back of the stopper 1 is provided with a guide member 3 . The inner side of the guide member 3 forms an inclined surface parallel to the inclined surface of the brake piece 1, and the outer side forms a vertical surface. , This vertical surface is clamped by the brake spring 6 . A roller 5 for guiding the movement of the brake piece 1 is provided between the brake piece 1 and the guide member 3. 4 denot...

no. 2 example

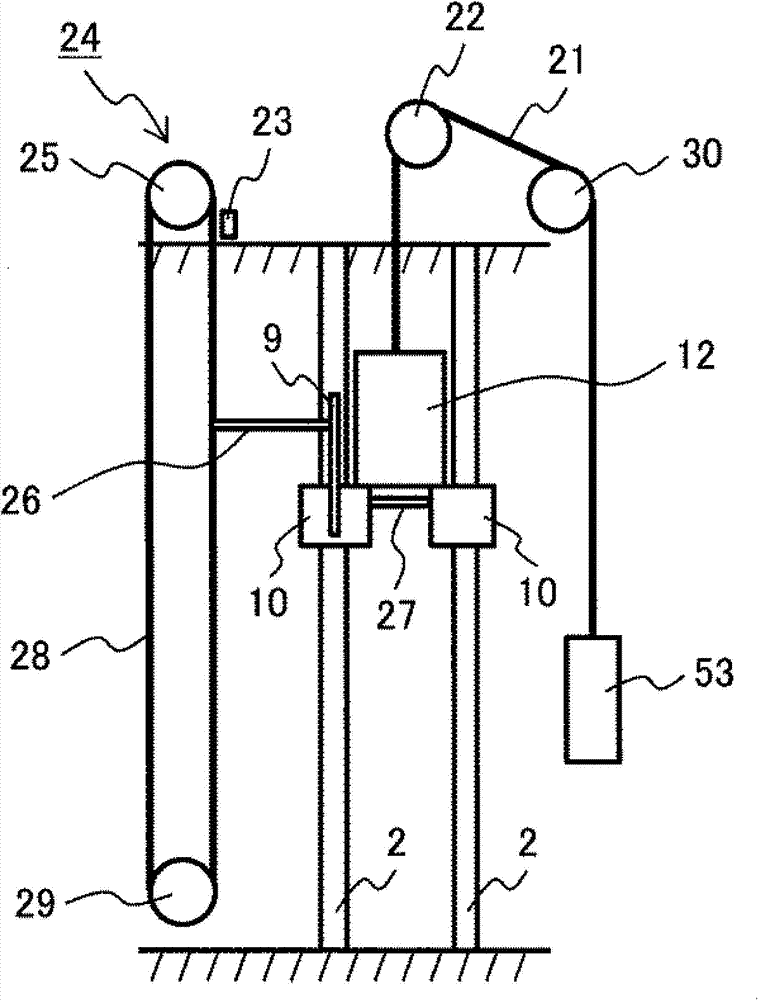

[0094] Figure 7 It is a schematic diagram of the emergency braking device concerning the 2nd Embodiment of this invention. The difference from the first embodiment described above lies in the holding mechanism 36 of the lifting member 31 . Therefore, repeated description of the stopper portion A of the clamping rail is omitted here.

[0095] A cylindrical locking portion 32 extending in the horizontal direction is attached to the lifting member 31 . On the other hand, various members for holding the locking portion 32 are provided on the elevator car 45 . Specifically, a rotation link 33 and a fixed link that are rotatable around a rotation shaft 34 are provided. An engaging portion 46 is provided below the base end portion of the rotation link 33 to prevent the rotation link 33 from moving clockwise from the illustrated position.

[0096] Conversely, when an upward force acts on the rotation link 33 , only the rotation link 33 rotates around the rotation axis. The fixed...

no. 3 example

[0109] Figure 10 It is a schematic diagram of the emergency braking device concerning the 3rd embodiment of this invention.

[0110] exist Figure 10 Among them, the holding mechanism 55 is composed of the drive mechanism 47 , the electromagnetic actuator 50 , the drive circuit 51 and the control circuit 52 .

[0111] In order to hold the locking portion 49 of the lifting member 48, a driving mechanism 47 having an electromagnetic actuator 50 movable in the horizontal direction is provided on the elevator car. The drive mechanism 47 is driven by the control circuit 52 and the drive circuit 51 . When the lifting member 48 is lifted to activate the emergency braking device, the drive mechanism 47 is energized to pull the electromagnetic actuator 50 in the direction shown by arrow 1. After the lifting action is completed, the power supply is cut off to activate the electromagnetic actuator 50. Return to the original position. The same is true at the time of resetting. The el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com