Driving assembly for parking braking calipers and manufacturing method for manufacturing driving assembly

A technology of driving components and manufacturing methods, applied in the direction of brake components, brake types, gear transmission mechanisms, etc., can solve the problems of unstable braking force, easy self-locking, low production cost, etc., achieve stable braking force and increase stability , the effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

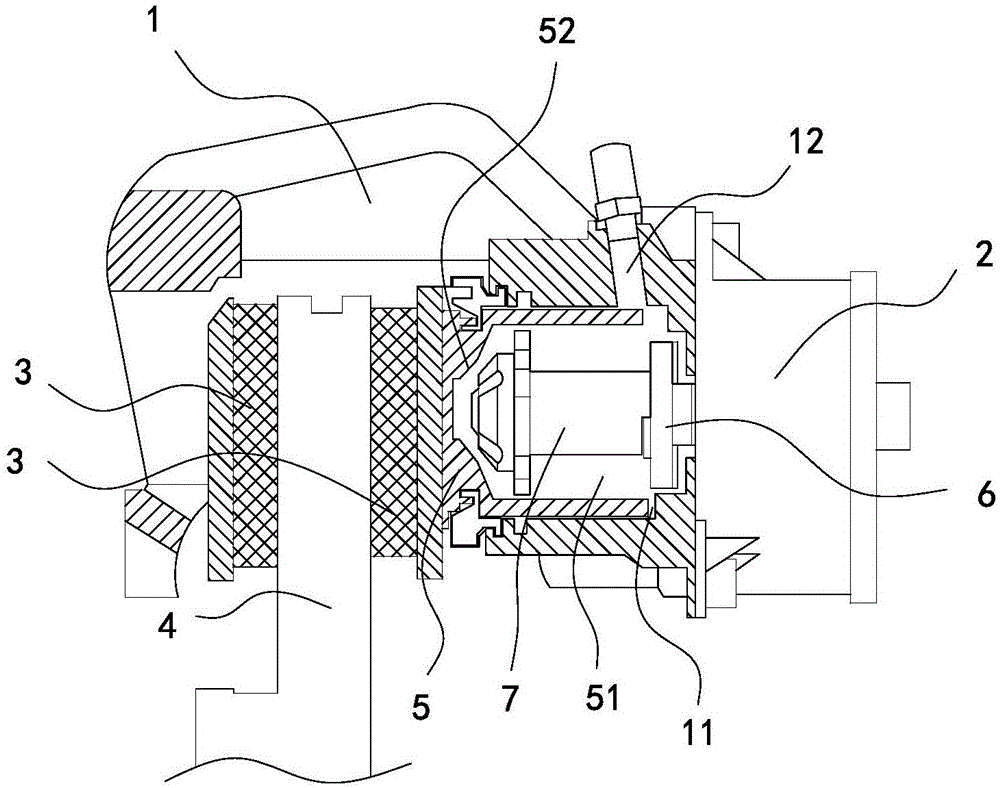

[0037] Such as Figures 1 to 4 , the present embodiment is a parking brake caliper, comprising a floating caliper main body 1, a motor 2 is installed on the floating caliper main body 1, a brake pad 3 for holding a brake disc 4 is installed in the floating caliper main body 1, the brake pad 3 There are two pieces, which are respectively located on different sides of the brake disc 4. A drive assembly is connected between the motor 2 and the brake pad 3. In this embodiment, a speed reduction device is installed on the main body 1 of the floating clamp, and the motor 2 is connected to the speed reduction device. device, the deceleration device is connected to the drive assembly, and when the motor 2 is running, the drive assembly is driven by the deceleration device, and the drive assembly drives two brake pads 3 to hold the brake disc 4 tightly.

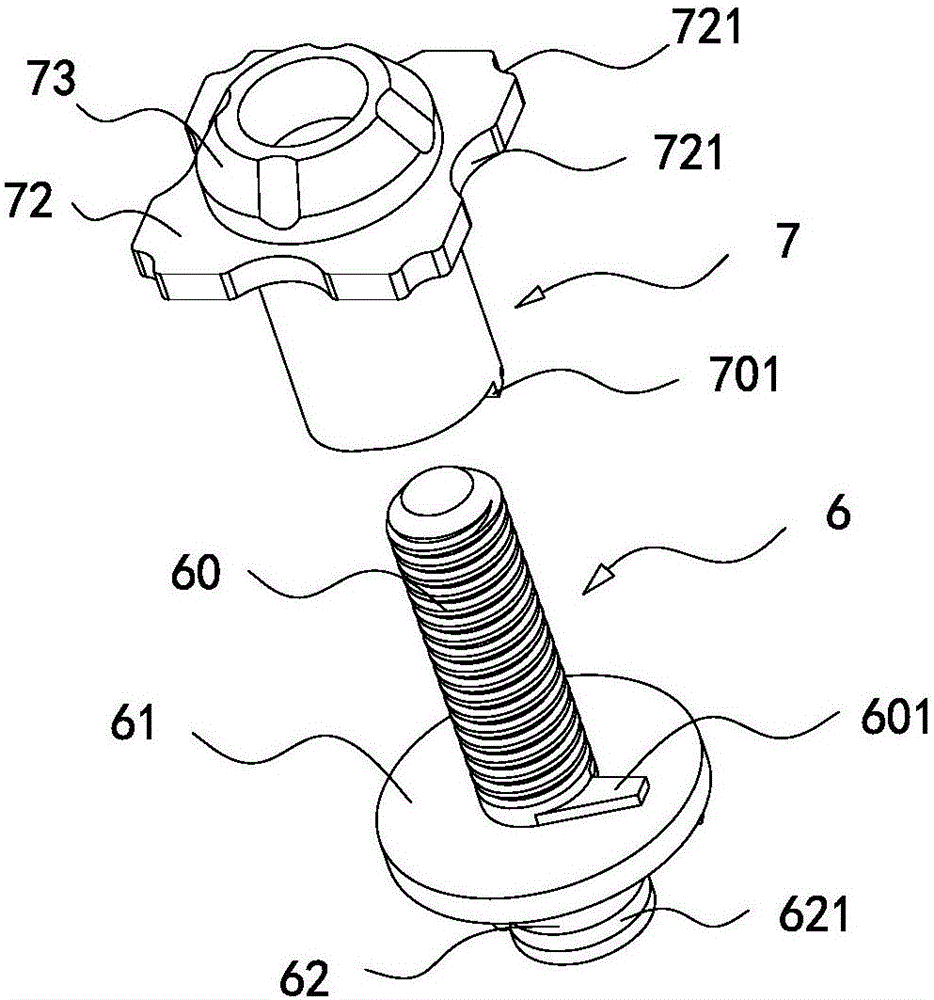

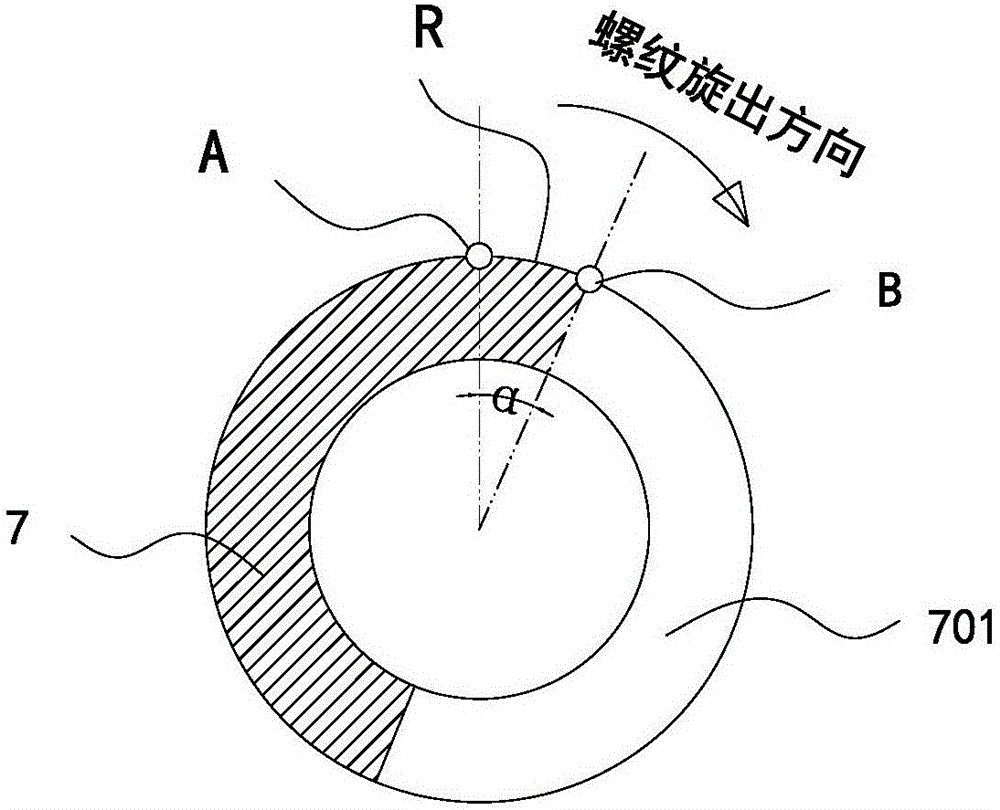

[0038] In this embodiment, the drive assembly includes a piston 5 for pushing against the brake pad 3, a screw rod 6 for transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com