Multi-rotor wind power generation system with cantilever beam

A technology of wind power generation system and cantilever beam, which is applied in the direction of wind power generator components, wind power generation, wind power engine, etc., can solve the problems of restricting the use of giant wind power units, land transportation, difficulty in installation, and difficulty in hoisting and dismounting, etc. Total installed capacity, benefits of integration, and the effect of mature manufacturing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The implementation of the present invention will be described in further detail below in conjunction with the accompanying drawings. The following detailed description is only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

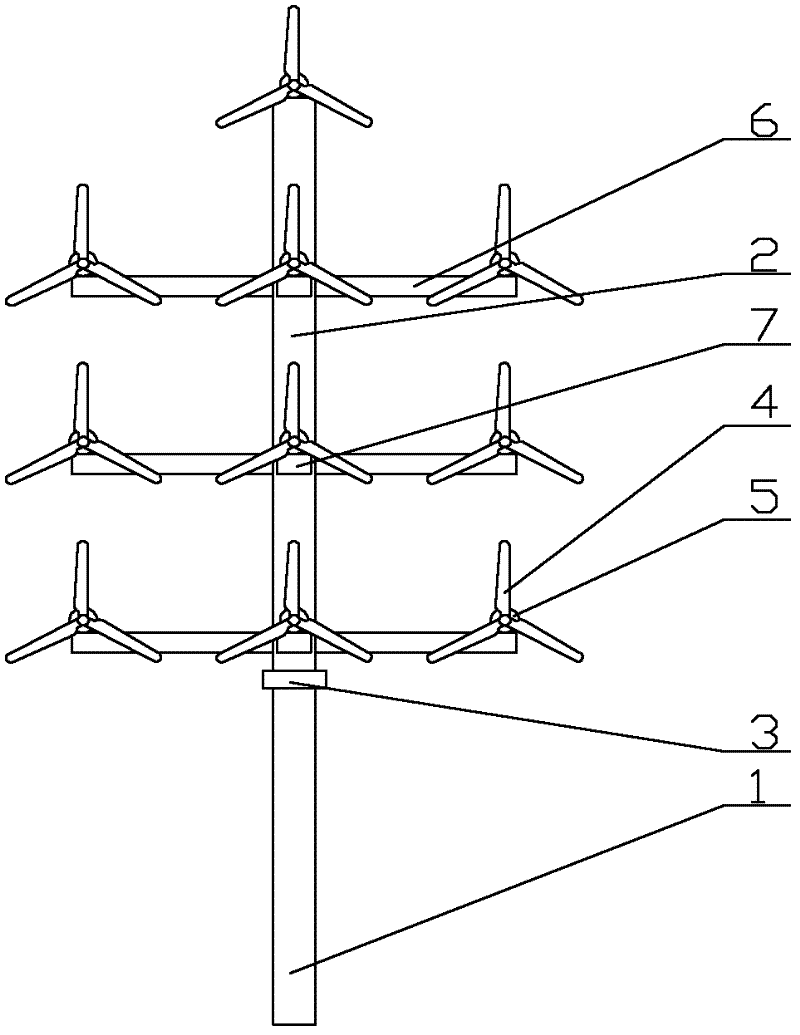

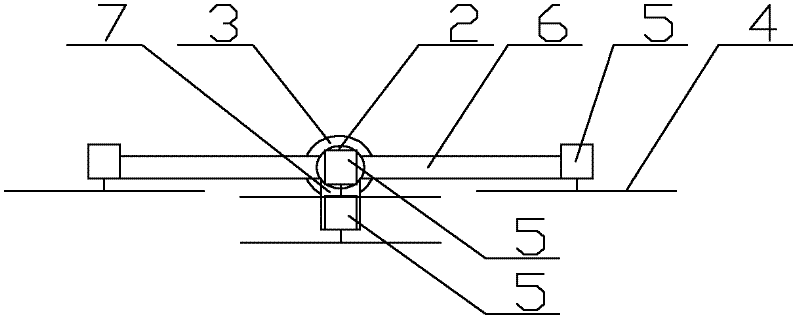

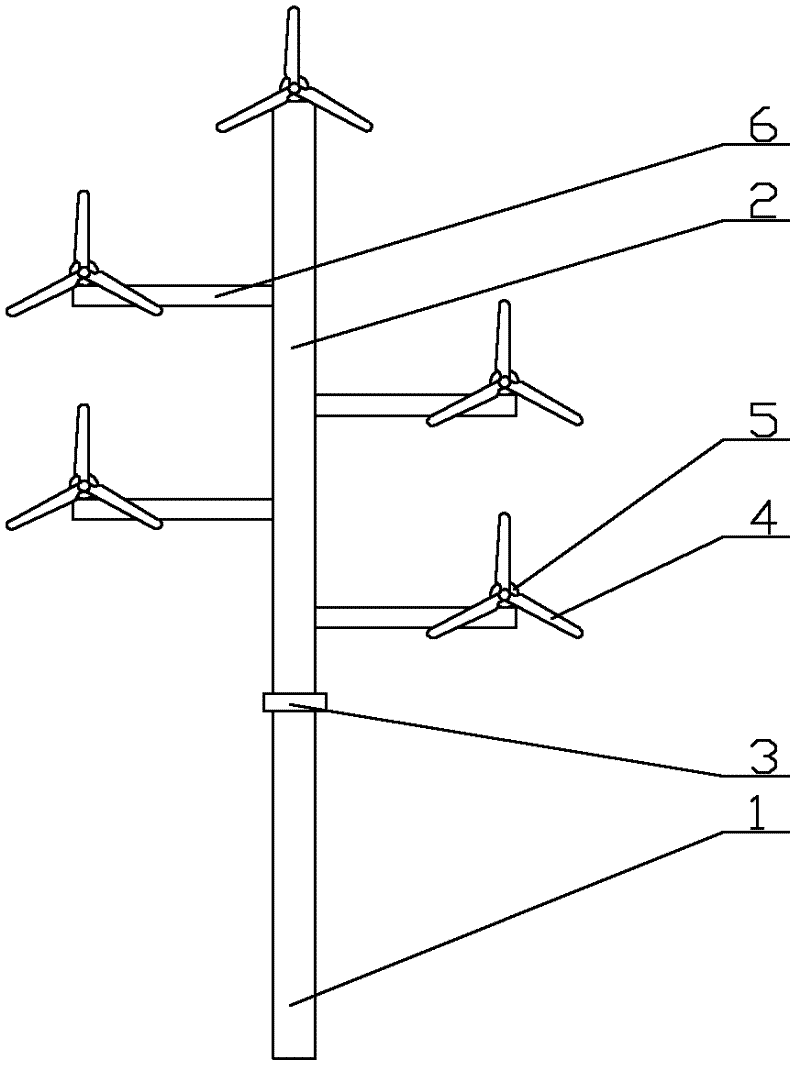

[0031] A multi-rotor wind power generation system with a cantilever beam, including a lower tower 1, a slewing drive device 3 and a wind turbine, and an upper tower 2, a cantilever beam 6 and a nacelle frame 7, and the slewing drive device is arranged on the upper tower and Between the lower towers, it is used to realize the overall rotation of the upper tower, cantilever beam, nacelle frame and wind turbine, one end of the cantilever beam is fixedly connected with the upper tower, the nacelle frame is set on the upper tower, and the wind turbine is directly installed On the top of the upper tower, the middle or outer end of the cantilever beam, or / and arranged on the nacelle frame, the wind turbine incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com