Mould for processing glass container

A glass container and mold technology, applied in the field of glass container processing molds, can solve problems such as short service life and easy deformation, and achieve the effects of ensuring service life, accelerating heat dissipation, and increasing production volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

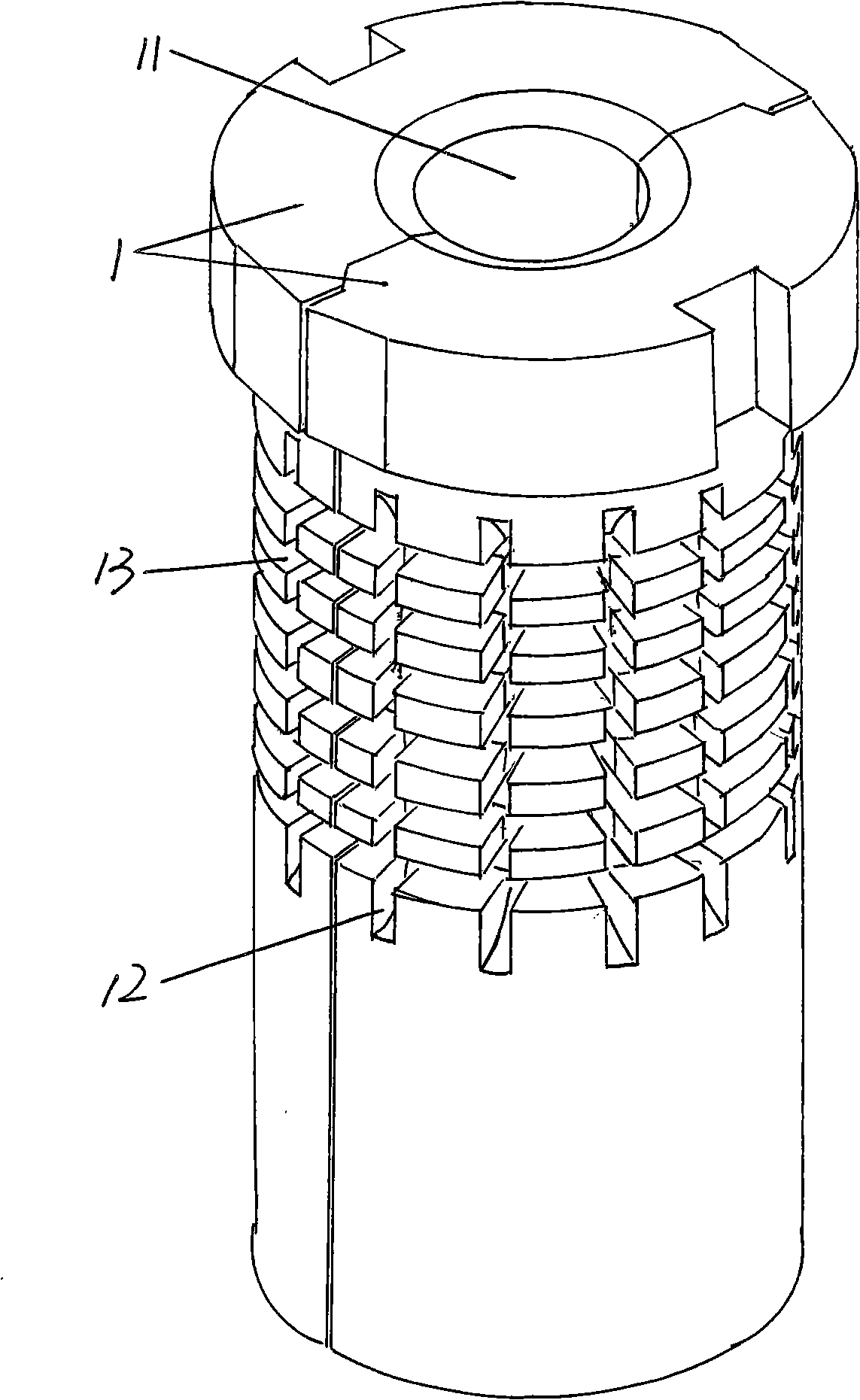

[0011] Please refer to the attached drawings. A pair of mold halves 1 are shown. A cavity 11 is machined inside each mold half 1. In use, the pair of mold halves 1 face each other and merge. In order to improve the heat dissipation effect of the pair of mold halves 1, without compromising the strength of the pair of mold halves 1, the applicant’s preferred solution is to install on the outer wall of the pair of mold halves 1, more specifically on the outer wall of the pair of mold halves 1. The outer wall of the upper region in the height direction of 1 is provided with a plurality of first and second heat dissipation grooves 12 and 13 at intervals, and the first and second heat dissipation grooves 12 and 13 form a cross-staggered relationship with each other.

[0012] According to the applicant, the mold for processing the glass container provided with the first and second heat dissipation grooves 12, 13 of the present invention and the mold without the first and second heat diss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com