Screw type corrugated plastic pipe material and its manufacturing method

A plastic pipe, spiral technology, applied in the direction of pipes, rigid pipes, mechanical equipment, etc., can solve the problems of difficult to guarantee the quality of welded joints, helical spring-like loosening, decomposition of plastic macromolecules and broken chains, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

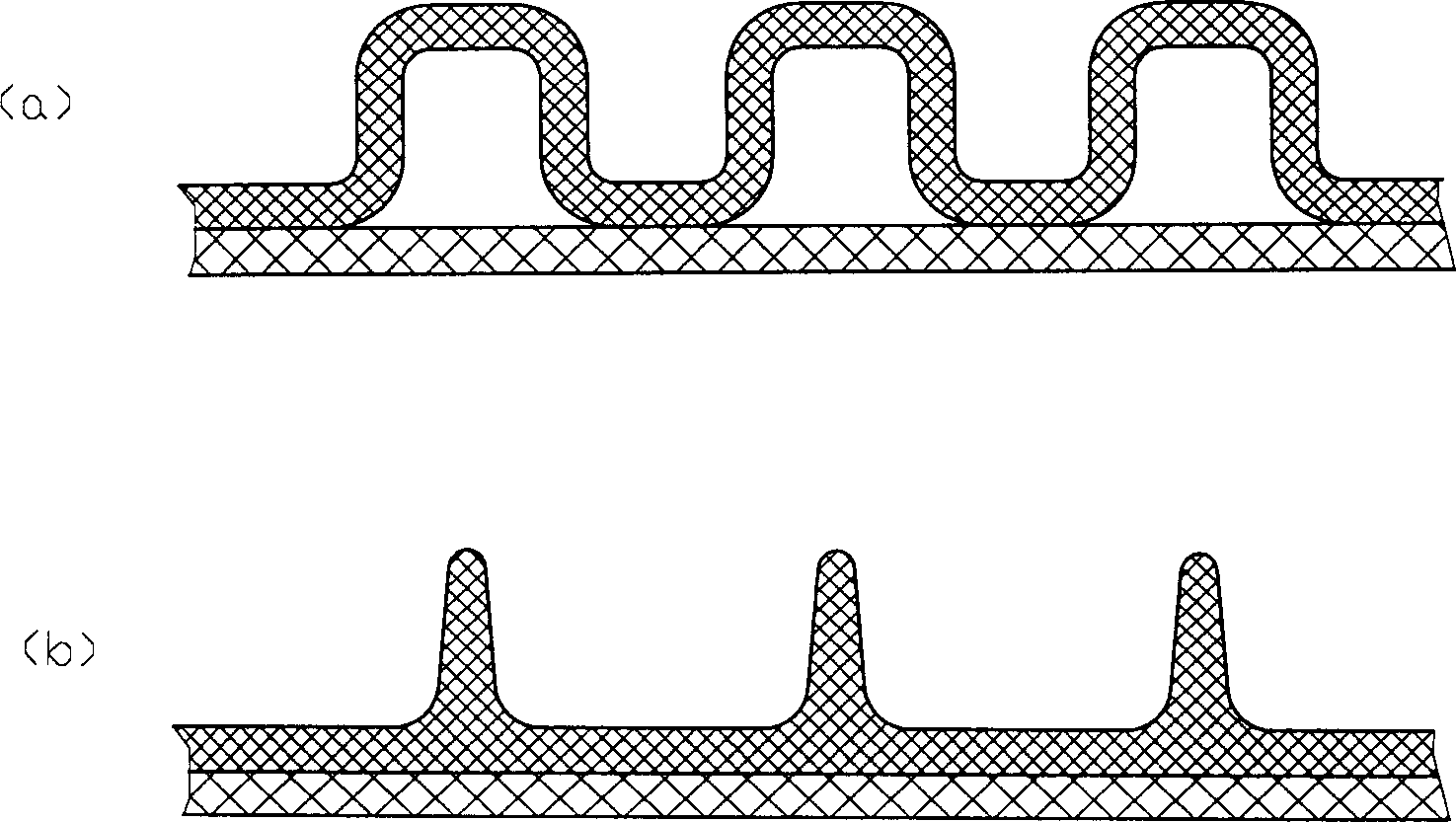

[0029] Figure 1 ~ Figure 3 It is the pipe wall structure form of several typical plastic pipes with different rib structures as mentioned above, and will not be described again.

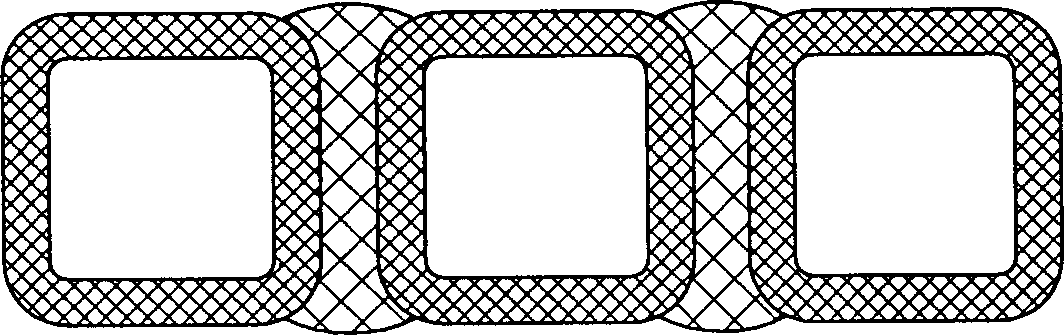

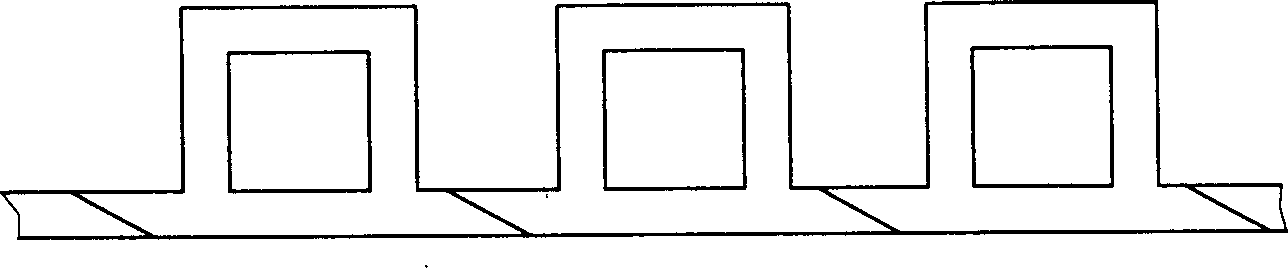

[0030] Figure 4 ~ Figure 6 It is the structure of several spiral corrugated plastic pipes in the structure form of the present invention. Its common basic structure is: the pipe wall of the pipe 1 is formed by a strip-shaped sheet 2 that is spirally wound with its center line as the axis, and the edges of the adjacent sheets in the spiral circumference are sequentially overlapped and fused. The continuous solid-wall tubular structure; the outer convex tendon-like reinforcement structure 4 in the same spiral winding form is joined to the pipe wall in a manner that spans the overlapping fusion seam 3 at the edge of each adjacent sheet material on the pipe wall. On the outer peripheral surface of the pipe wall structure, it is formed as a spiral corrugated plastic pipe with a helically wound externa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com