Production method of full-dull polyester fiber

A technology of polyester fiber and full extinction, which is applied in fiber treatment, fiber chemical characteristics, single-component polyester rayon, etc. The market demand for matting slices is not large, and the effects of overcoming spinning difficulties, soft fabric luster, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

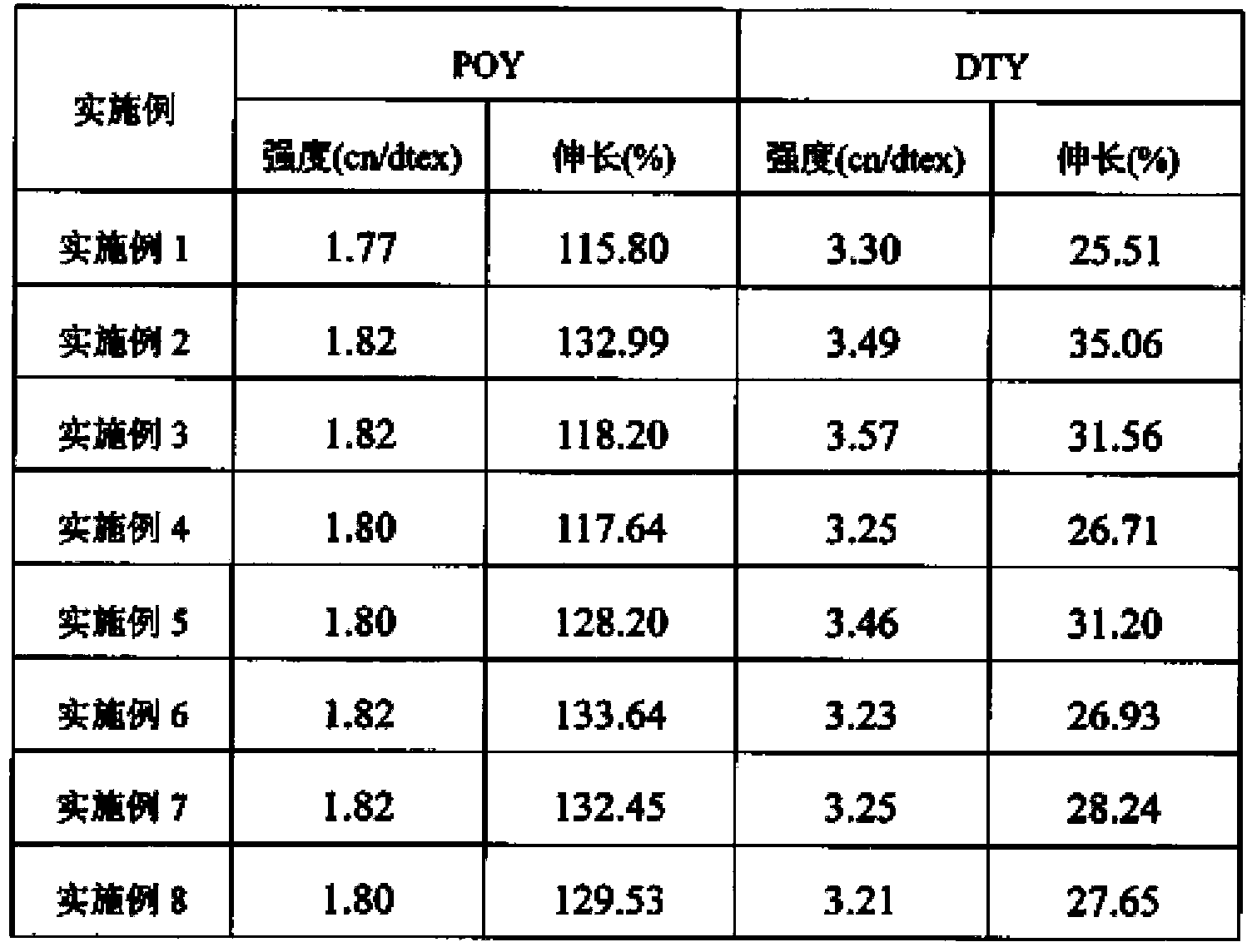

Examples

Embodiment 1

[0015] The sheath-core composite spinning assembly is used for melt spinning. The core components are all made of semi-dull PET chips with a TiO2 content of 0.2%-0.5%, and 97.5% of the skin components are also the above-mentioned semi-dull PET chips. 2.5% of the total is the full matt masterbatch imported from a major Japanese ink company containing TiO250%, and the total amount of cortex components accounts for 30% of all raw material slices. The spinning process is: chip conveying→drying→masterbatch adding device metering and mixing→screw extruder→melt filter→spinning box→metering pump→spinneret assembly→side blowing→cooling→winding. The spinning temperature is controlled at 290-295° C., and the spinning speed is 3000-4000 m / min to obtain full-dull POY winding yarn. The POY winding wire is further processed into DTY through double-zone thermal stretching, with a draw ratio of 1.58-1.72. The temperature of the deformation heating box is controlled at 190-220°C, the temperatur...

Embodiment 2

[0017] Same as Example 1, wherein 5.0% of the full matt masterbatch is added to the skin layer component.

Embodiment 3

[0019] Same as Example 1, wherein the total amount of cortex components accounts for 20% of all raw material slices.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com