Aqueous environment-friendly anti-aging floor coating and preparation method thereof

A floor coating and anti-aging technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as threats to human health, poor aging resistance, and failure to meet environmental protection requirements, and achieve outstanding UV resistance, Good stain resistance, good UV resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

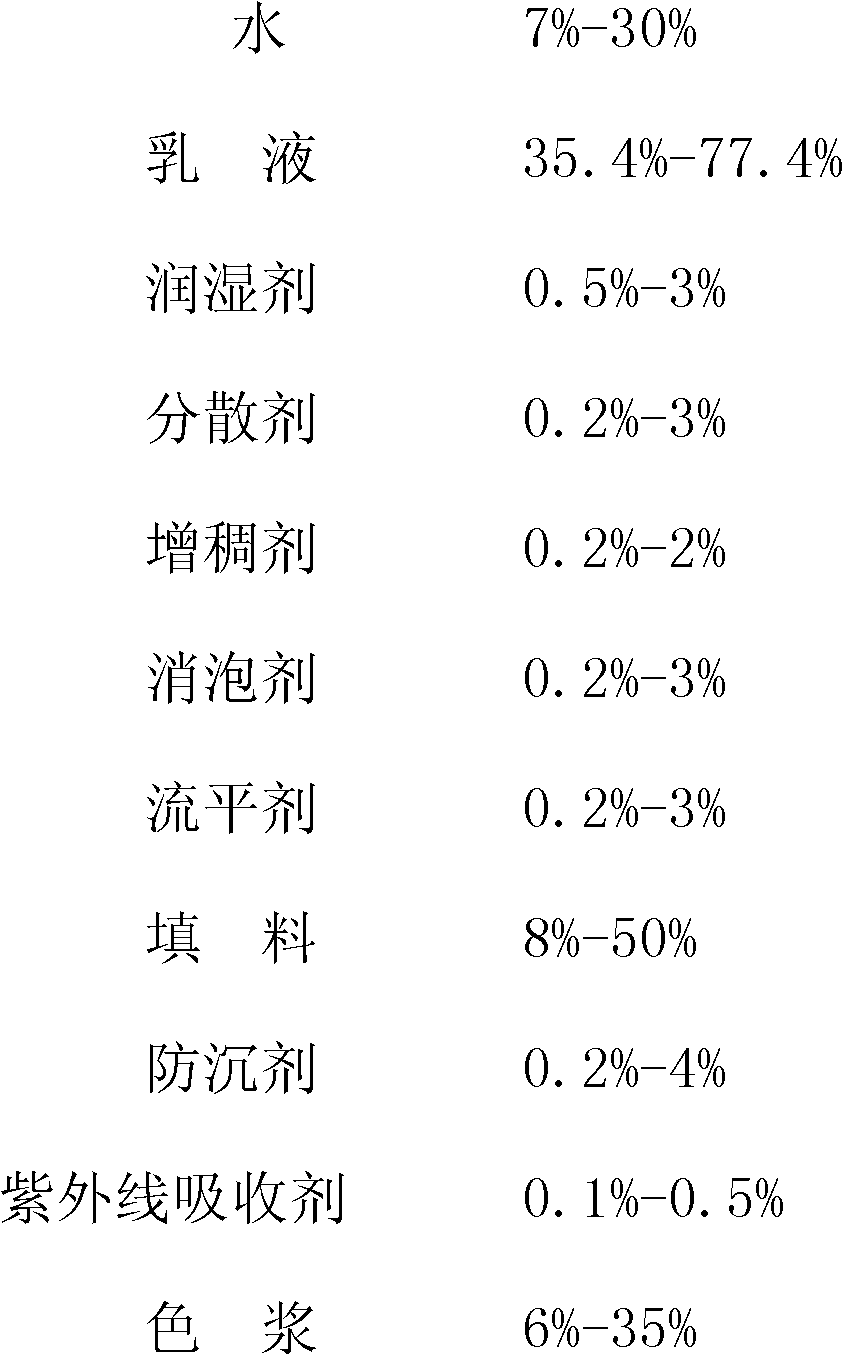

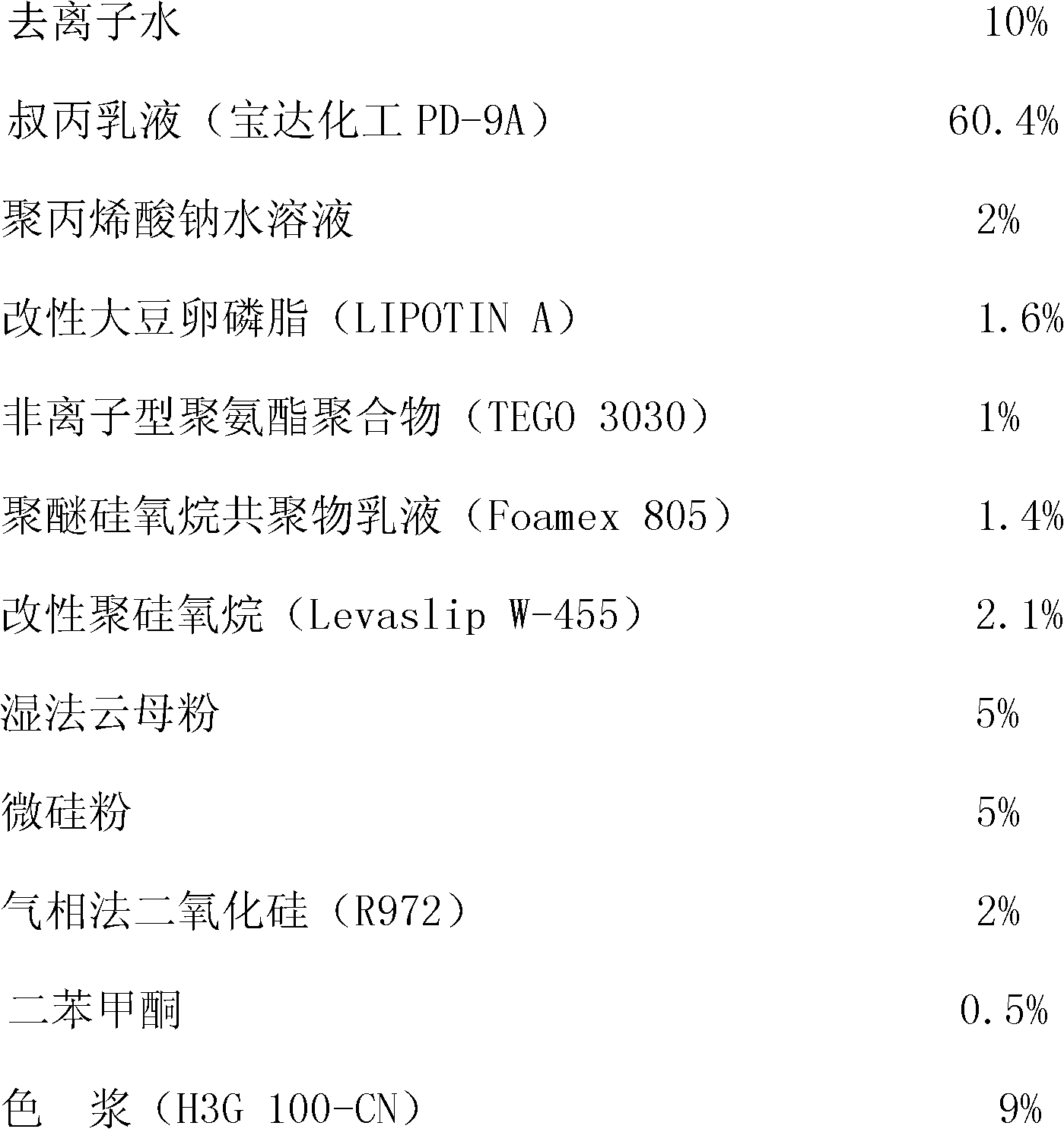

[0037] Embodiment one: described water-based environment-friendly anti-aging floor paint, comprises A, B component, and the composition and weight percent of each component are as follows:

[0038] Component A

[0039]

[0040] Component B

[0041] Bayer HDI 90%

[0042] Stannous octoate 10%

[0043] A method for preparing the above water-based environment-friendly and aging-resistant floor paint is characterized in that:

[0044] Component A: first put 10% of the deionized water in the above group A distribution into the dispersion tank and stir at 300-500 rpm while adding 1% of non-ionic polyurethane polymer (TEGO 3030), and then add 2% of poly Sodium acrylate aqueous solution, 1.6% modified soybean lecithin (LIPOTIN A of EVONIK company), 1.4% polyether siloxane copolymer emulsion (Foamex 805 of TEGO company), 5% wet-process mica powder (Shijiazhuang Xinghai High-tech non-metallic material Co., Ltd.), 5% micro-silica fume (Huzhou Jingyuan Quartz Products Factory), and...

Embodiment 2

[0047] Embodiment two: described water-based environment-friendly anti-aging floor paint, comprises A, B component, and the composition and weight percent of each component are as follows:

[0048] Component A

[0049]

[0050]

[0051] Component B

[0052] Isophorone Diisocyanate 95%

[0053] Stannous octoate 5%

[0054] A method for preparing the above water-based environment-friendly and aging-resistant floor paint is characterized in that:

[0055]Component A: First put 15% of the deionized water in the above component A into the dispersion tank and stir at 300-500 rpm while adding 0.2% modified urea solution (BYK420), then add 0.5% sodium polyacrylate aqueous solution , 0.5% modified soybean lecithin (LIPOTINA of EVONIK company), 0.3% polydimethylsiloxane emulsion (Foamex 835 of TEGO company), 25% wet-process mica powder (Shijiazhuang Xinghai Gaoke Non-metallic Materials Co., Ltd. ), 5% of precipitated barium sulfate (Jinan Jinxing barium sulfate sand processing...

Embodiment 3

[0059] The water-based environment-friendly anti-aging floor paint includes components A and B, and the composition and weight percentage of each component are as follows:

[0060] Component A

[0061]

[0062]

[0063] Component B

[0064] Isophorone Diisocyanate 97%

[0065] Zinc Caprylate 3%

[0066] A method for preparing the above water-based environment-friendly and aging-resistant floor paint is characterized in that:

[0067] Component A: first put 12% of the deionized water in the above group A distribution into the dispersion tank and stir at 300-500 rpm while adding 0.6% of non-ionic polyurethane polymer (TEGO 3030), and then add 1.1% of High pigment affinity group copolymer aqueous solution (TEGO 752W), 0.8% polyacrylic acid ammonium salt, 0.8% polyether siloxane copolymer emulsion (TEGO company Foamex805), 20% wet-process mica powder (Shijiazhuang Xinghai Hi-Tech non- Metal Materials Co., Ltd.), and then disperse at a high speed of 1000-1500 rpm for 20-3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wear resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com