Black surface composite coating and preparation method thereof

A surface composite and coating technology, which is applied in the field of black surface composite coating and its preparation, can solve problems such as easy to see, poor scratch resistance, and obvious color contrast difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

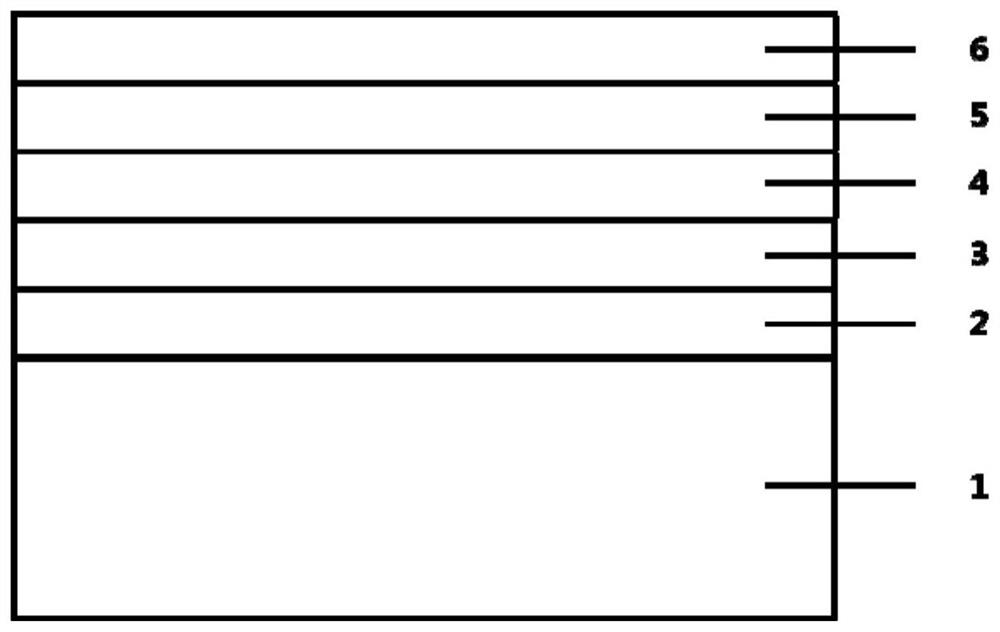

Image

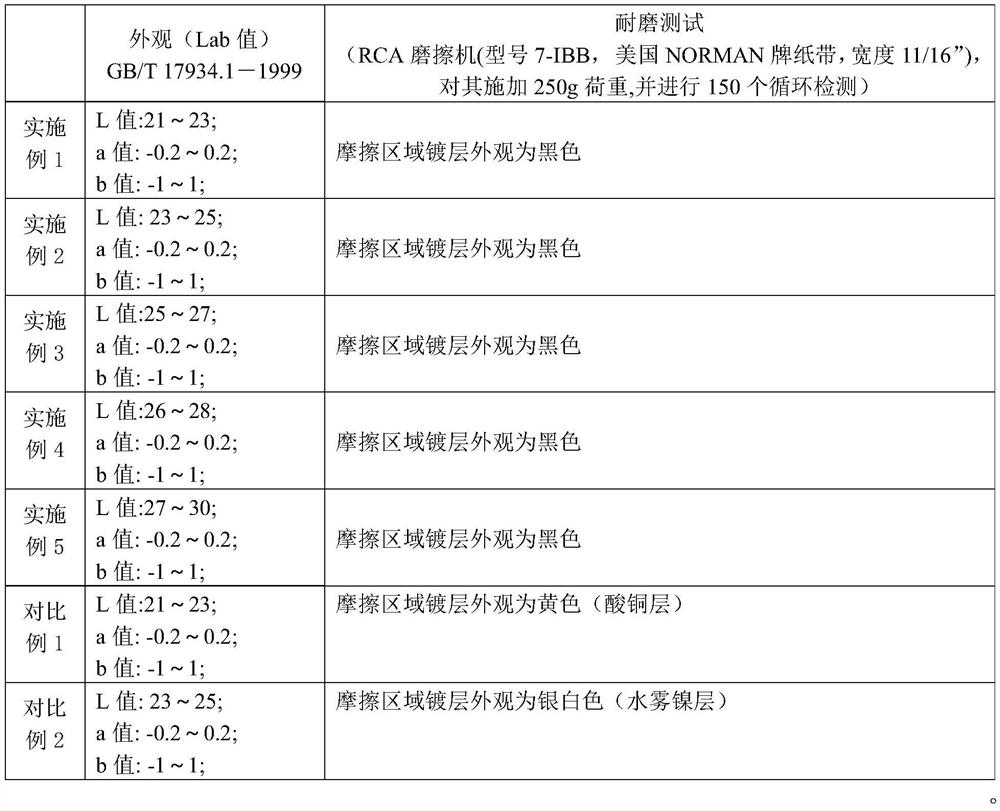

Examples

Embodiment 2

[0039] The preparation method is basically the same as that of Example 1, except that, when the black nickel layer is electroplated, the black nickel electroplating time is changed, and the black nickel electroplating time is 2700s.

Embodiment 3

[0041] The preparation method is basically the same as that of Example 1, except that, when the black nickel layer is electroplated, the black nickel electroplating time is changed, and the black nickel electroplating time is 3000s.

Embodiment 4

[0043] The preparation method is basically the same as that of Example 1, except that, when the black nickel layer is electroplated, the black nickel electroplating time is changed, and the black nickel electroplating time is 3300s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com