Low-gloss low-smoke halogen-free flame-retardant polycarbonate composite material

A technology of flame-retardant polycarbonate and composite materials, which is applied in the field of polymer composite materials and can solve the problems of unimproved flame-retardant and low-smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

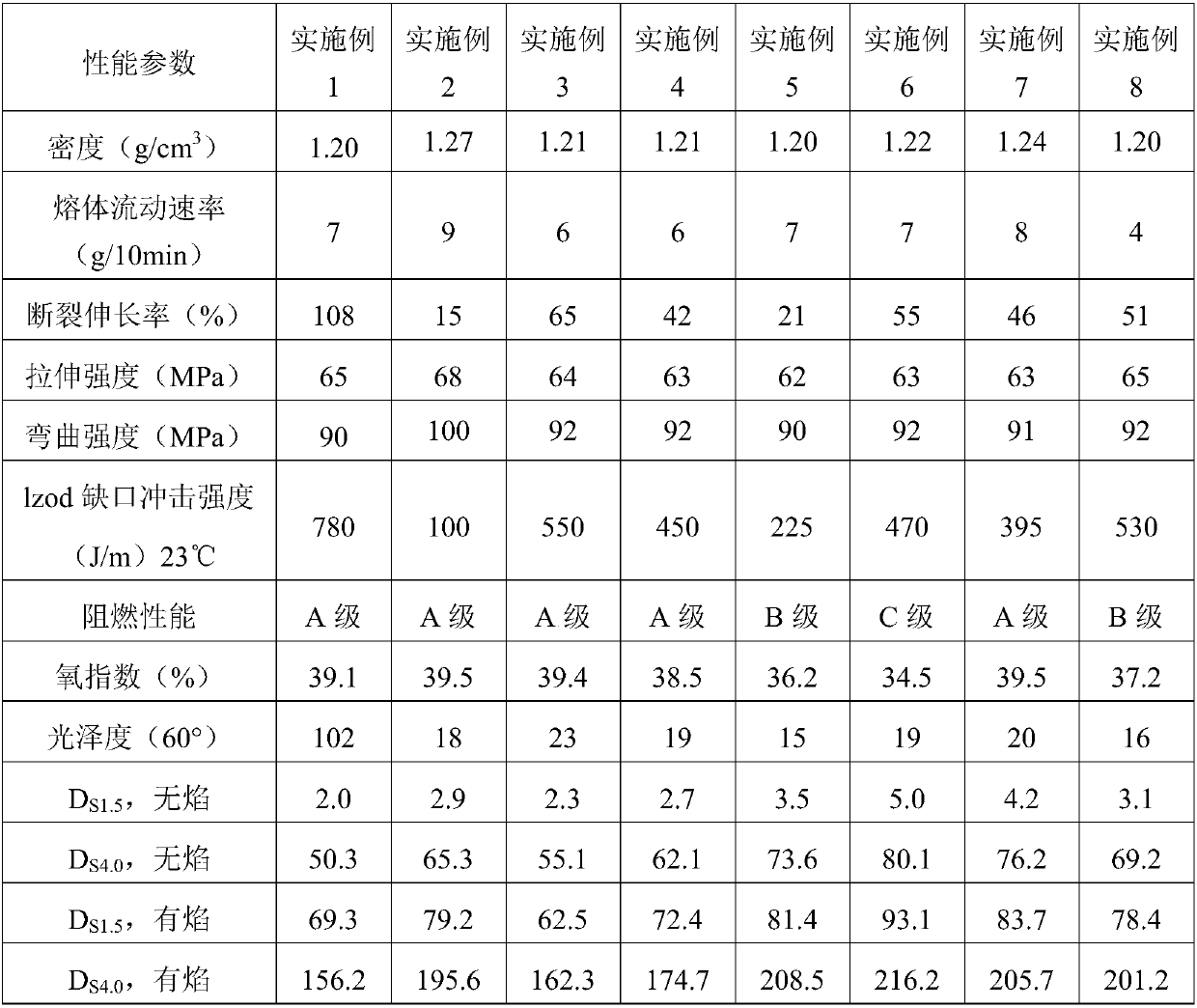

[0049] Components and proportioning of table 1 embodiment 1-8

[0050]

[0051] Preparation method: After weighing the raw materials according to the ratio in Table 1, the raw materials were mixed in a high-speed mixer for 3 minutes, then extruded through a twin-screw extruder at 250-260 ° C, cooled, and granulated. After drying for 4 hours at 260-280°C, it is injection molded into a standard sample.

Embodiment 9

[0052] Embodiment 9: Evaluation of Implementation Effect

[0053] The samples obtained in the above-mentioned Examples 1 to 8 were tested for mechanical properties and gloss according to the American Society for Testing and Materials (ASTM) standard, tested for oxygen index according to GB / T 2406.2-2009, tested according to UIC 564-2:1991 standard For flame retardant properties, the specific optical density of smoke is tested according to GB / T 8323.2-2008 "Plastic - Smoke Generation - Part 2: Test Method for Measuring Smoke Density by Single Chamber Method". The test results are shown in Table 2 below:

[0054] Table 2 performance test results

[0055]

[0056] Remarks: Ds1.5—the specific optical density of smoke at 1.5 minutes from the beginning of the test;

[0057] Ds4.0—the specific optical density of smoke at 4.0 minutes from the beginning of the test.

[0058] The test performance results in Table 2 show that:

[0059] (1) From the analysis of Examples 1 to 4, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com