Anti-sticking cream and preparation method thereof

A technology of anti-adhesive and dimethyl silicone oil, which is applied in the direction of coating, etc., can solve the problems of difficult to guarantee the stability of coating, difficult to guarantee anti-adhesive performance, poor stability of gasoline, etc., and achieve outstanding curability, safe method and easy peeling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

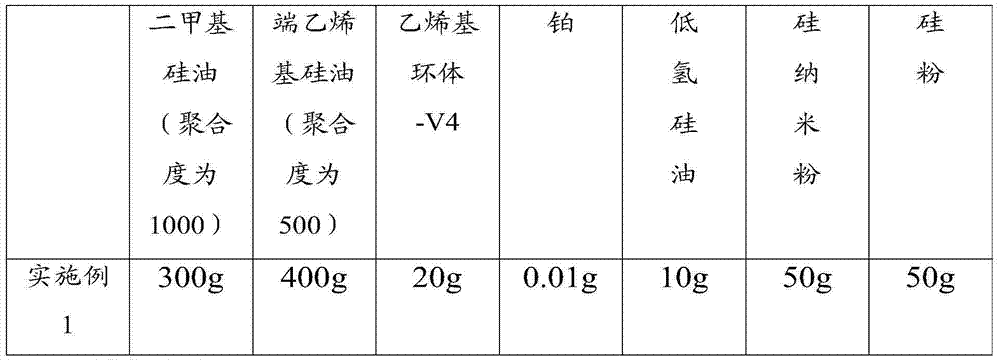

[0030] Table 1 Raw material composition and consumption

[0031]

[0032] Preparation:

[0033] Mix the dimethyl silicone oil, vinyl-terminated silicone oil, vinyl ring body-V4, platinum, and low-hydrogen silicone oil evenly and react at 20°C, then add silicon nanopowder and silicon powder and stir.

[0034] In order to ensure that each raw material is fully reacted, stirring is carried out during the reaction process, and the stirring rate is 100 rad / min to obtain a non-toxic, tasteless, flame-retardant and fire-resistant anti-sticking paste.

Embodiment 2

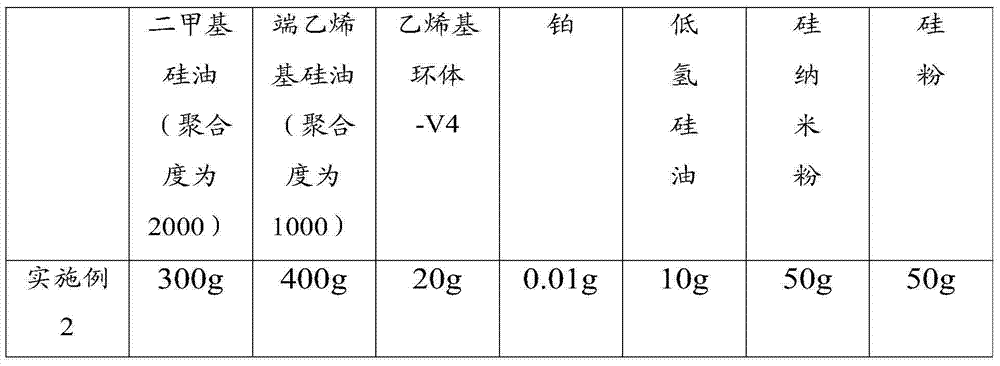

[0036] Table 2 raw material composition and consumption

[0037]

[0038] Preparation:

[0039] Mix the simethicone oil, vinyl-terminated silicone oil, vinyl ring body-V4, platinum, and low-hydrogen silicone oil evenly and react at 25°C, then add silicon nanopowder and silicon powder and stir.

[0040] In order to ensure that each raw material is fully reacted, stirring is carried out during the reaction process, and the stirring rate is 100 rad / min to obtain a non-toxic, tasteless, flame-retardant and fire-resistant anti-sticking paste.

Embodiment 3

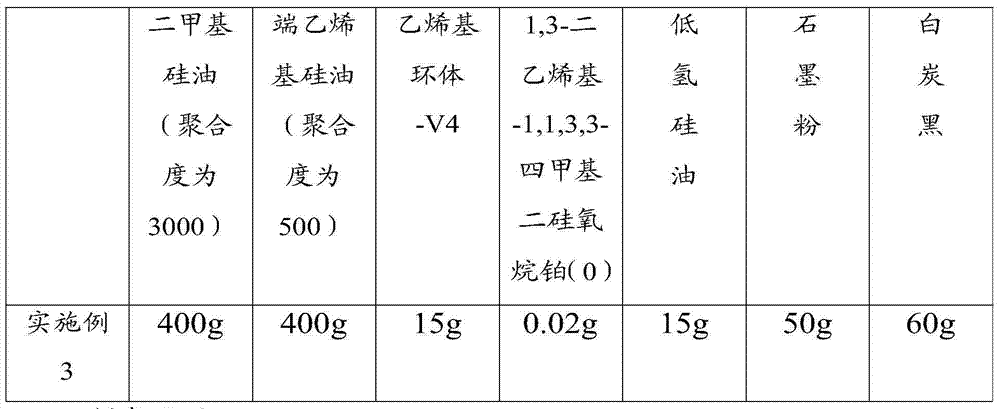

[0042] Table 3 raw material composition and consumption

[0043]

[0044] Preparation:

[0045] The simethicone, vinyl-terminated silicone oil, vinyl ring body-V4, 1,3-divinyl-1,1,3,3-tetramethyldisiloxane platinum (0), low hydrogen Mix the silicone oil evenly and react at 20°C, then add graphite powder and white carbon black and stir.

[0046] In order to ensure that each raw material is fully reacted, stirring is carried out during the reaction process, and the stirring rate is 100 rad / min to obtain a non-toxic, tasteless, flame-retardant and fire-resistant anti-sticking paste.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com