A low-gloss thermoplastic polyurethane composition and its preparation method and application

A thermoplastic polyurethane and thermoplastic polyester technology, applied in the field of thermoplastic polyurethane composition and its preparation, can solve the problems of poor processing performance of cross-linked structural elastomer, poor uniformity of matting effect, poor compatibility of matting agent, etc., and achieve excellent mechanical properties. , The matting effect is uniform and delicate, and the processing is easy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

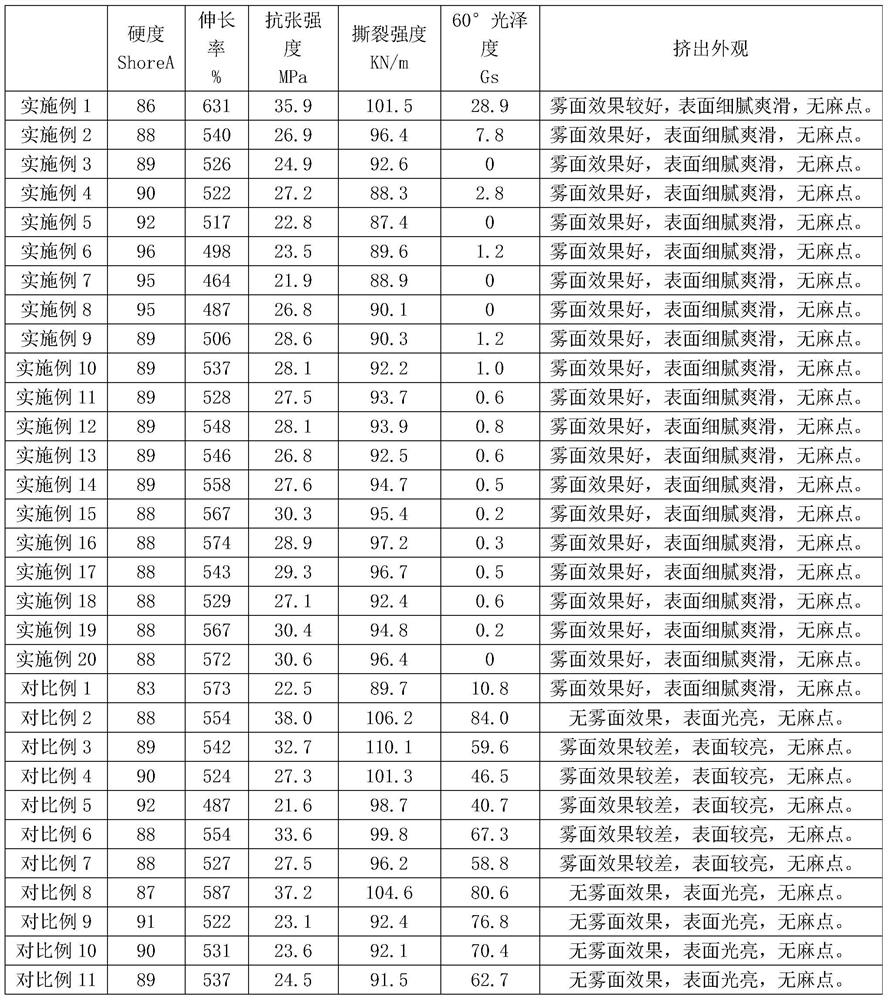

[0073] The composition is prepared by melt blending of a twin screw extruder, and the physical property test specimen is prepared by conventional injection molding machine processing.

[0074] The gloss test is measured by extruding a thin sheet with a thickness of about 1 mm and a width of about 40 mm by a single screw extruder. According to ASTM D523, the surface gloss of the sheet is tested with the MN268 gloss meter.

[0075] Mechanical properties tested according to ASTM D412.

[0076] Test the hardness of the specimen according to ASTM D2240.

Embodiment 1

[0078] Mix 95% thermoplastic polyester polyurethane (1185EC), 3% nylon 6 and 2% magnesium silicate according to the mass percentage. The mixed composition is melted and blended in a φ42mm co-rotating twin screw extruder at a blending temperature of 175-230 °C. Extruded splines are cooled by water and air-dried, pelletized to obtain composition particles. After drying the pellets at 80 °C for 16 h, test samples are prepared and their relevant properties are tested.

Embodiment 2

[0080] According to the mass percentage, 85% of the thermoplastic polyester polyurethane (1185EC), 10% of nylon 1010 and 5% of the sodium phosphate of the methyl bran bis (2,4-diltetylphenoxy) were mixed evenly. The mixed composition is melted and blended in a φ42mm co-rotating twin screw extruder at a blending temperature of 175-220 °C. Extruded splines are cooled by water and air-dried, pelletized to obtain composition particles. After drying the pellets at 80 °C for 16 h, test samples are prepared and their relevant properties are tested.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com