Direct vacuum aluminum plating water-based under-coating paint composition and preparation method thereof

A technology of vacuum aluminum plating and composition, which is applied in paper coating, polyurea/polyurethane coating, coating, etc., can solve the problems of insufficient stiffness, aluminum plating, etc., and achieve low VOC content, good film-forming property, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

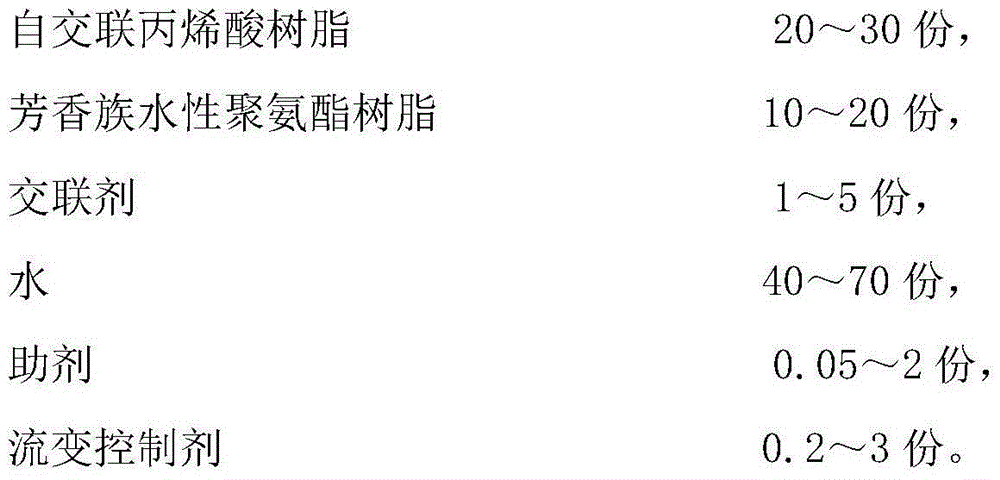

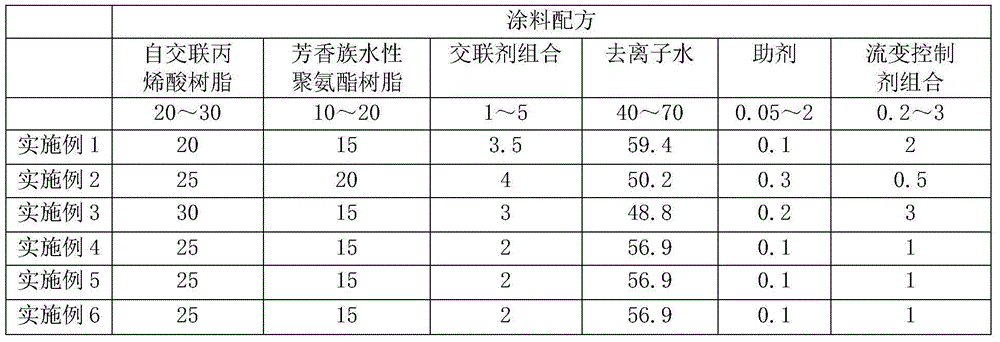

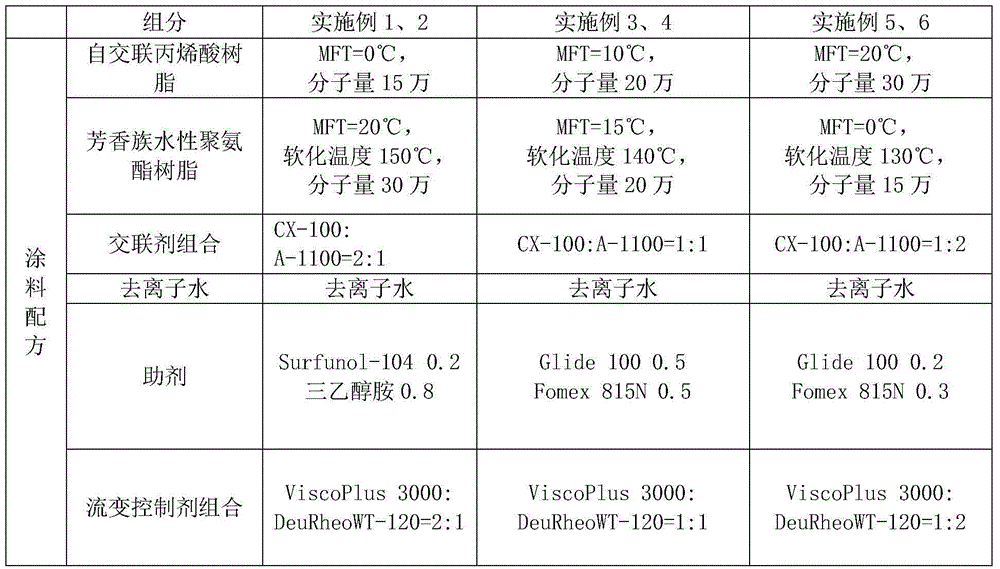

[0031] The embodiment relates to the direct vacuum aluminum plating water-based primer coating composition: the coatings described in Examples 1 to 6 include parts by weight as shown in Table 1 below, and the specific components are shown in Table 2 below:

[0032] Table 1

[0033]

[0034] Table 2

[0035]

Embodiment 7

[0037] According to the formula provided in Examples 1 to 3, this example provides a method for preparing a direct vacuum aluminized water-based primer coating composition, comprising the following steps:

[0038] Step 1. Put the self-crosslinking acrylic resin and the aromatic water-based polyurethane resin in the reaction kettle and stir for 5 minutes at a low speed, and the stirring rate is 100 rpm;

[0039] Step 2. Increase the stirring speed to 300rpm, add crosslinking agent and water to the reaction kettle in turn, and continue stirring for 5 minutes;

[0040] Step 3: Add additives to the reaction kettle one by one, control the pH value of the coating at 7-8, and stir for 15 minutes;

[0041] Step 4: Add the rheology control agent, control the viscosity at 30-40s (coat in 4 cups, 25°C), stir for 10 minutes; filter to obtain the direct vacuum aluminized water-based primer; the pore size of the filter is 300 mesh.

Embodiment 8

[0043] According to the formula provided in Examples 4 to 6, this example provides a method for preparing a direct vacuum aluminized water-based primer coating composition, comprising the following steps:

[0044] Step 1. Put the self-crosslinking acrylic resin and aromatic water-based polyurethane resin in the reaction kettle and stir at a low speed for 10 minutes, and the stirring rate is 200 rpm;

[0045] Step 2. Increase the stirring speed to 500rpm, add crosslinking agent and water to the reaction kettle in turn, and continue stirring for 10 minutes;

[0046] Step 3: Add additives to the reaction kettle one by one, control the pH value of the coating at 8, and stir for 10 minutes;

[0047] Step 4: Add a rheology control agent, control the viscosity at 30-40s (coat in 4 cups, 25°C), stir for 15 minutes; filter to obtain a direct vacuum aluminized water-based primer; the pore size of the filter is 300 mesh.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com