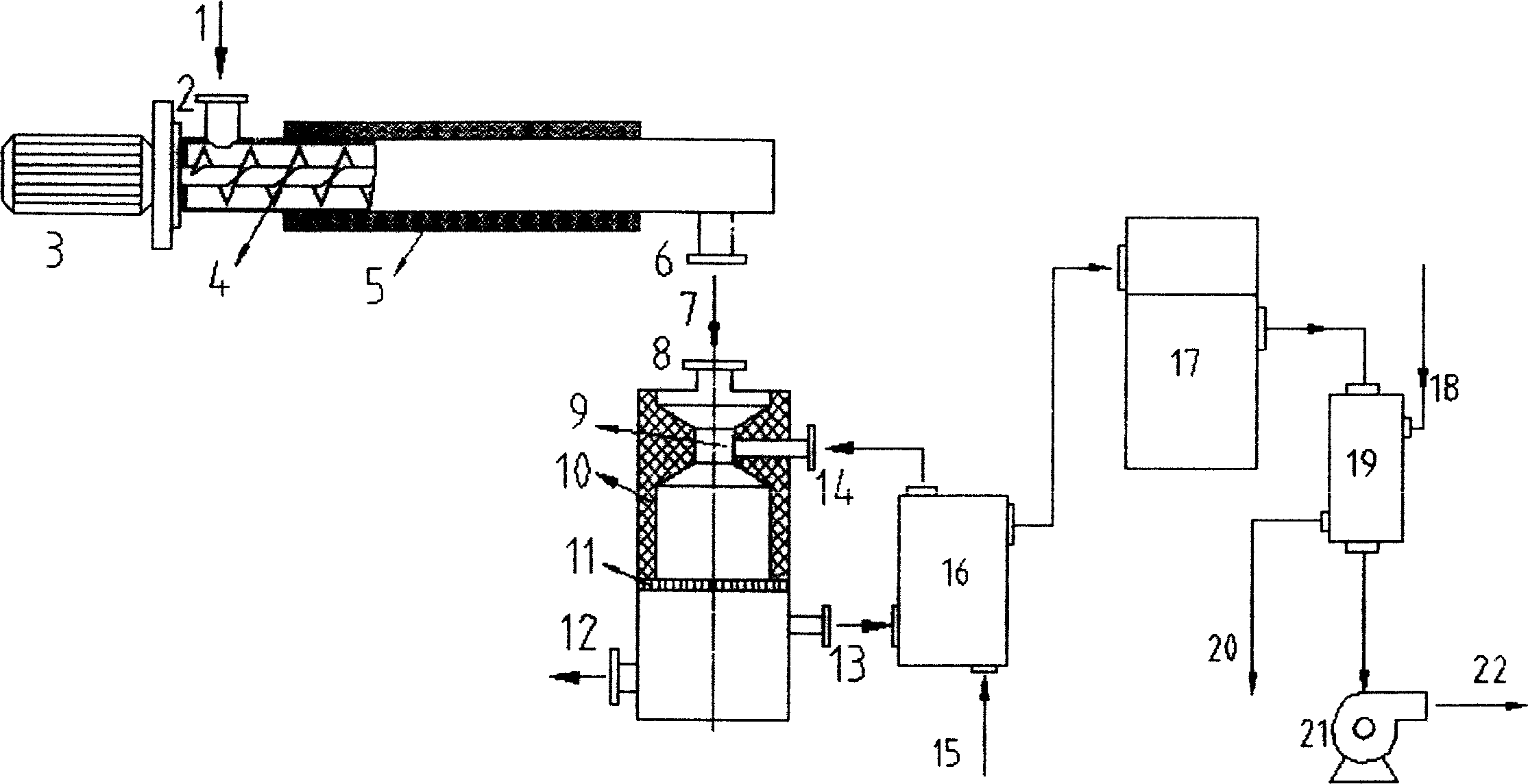

Low-tar biomass gasifying method and apparatus

A gasification device and biomass technology, applied in coking ovens, petroleum industry, special forms of dry distillation, etc., can solve problems such as unusable tar, secondary pollution of tar liquid, waste of water sources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

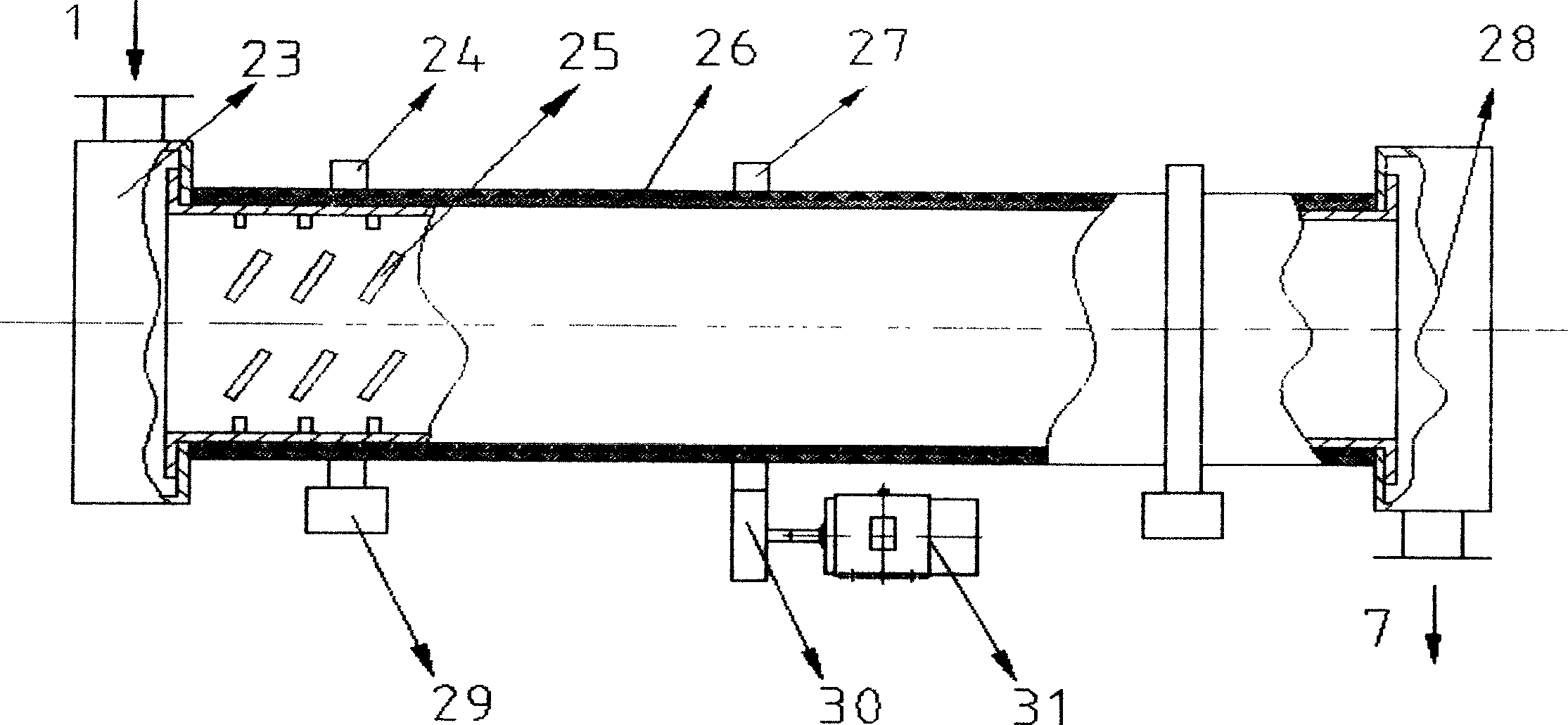

Embodiment 1

[0018] Use peanut shells as gasification raw materials without crushing, put them into the quantitative feeder (2), pass hot flue gas into the pyrolysis reactor to preheat the system, and start the motor (3) to start feeding , the feed rate is about 50kg / h, the peanut shells enter the pyrolysis reactor, and are screwed under the action of mechanical force, and the pyrolysis reaction occurs, and the pyrolysis products (including pyrolysis gas and residual carbon) all enter the cracking gasifier In the process, an incomplete oxidative combustion reaction occurs with the thermal oxidant that is controlled to pass through the upper part, that is, air (14), forming a high temperature zone (9), about 1000 ° C, at this time, the heavy hydrocarbons of macromolecules are cracked at high temperature It is a small molecular gas, and the unburned residual carbon falls on the grate (11) below, and the cracked gas passes through the hot carbon layer below and undergoes a reduction reaction w...

Embodiment 2

[0020] The raw material is replaced with corn stalks, processed by a hay cutter, the length should be less than 10cm, the feed rate is about 35kg / h, the temperature of the pyrolyzer is about 400°C, the high temperature zone of the pyrolysis gasifier is controlled at 900°C, and the rest Steps and methods are the same as in Embodiment 1. The gas composition obtained is: CO 12.24%, CO 2 19.65%, CH 4 2.58%, O 2 0.74%, H 2 16.48%, C 2 The above ingredients are 0.64%, N247.67%; the calorific value of gas is 4.68MJ / m 3 .

Embodiment 3

[0022] The raw material is replaced by corncobs without crushing, the feed rate is about 70kg / h, the temperature of the pyrolyzer is 650°C, the high temperature zone of the cracking gasifier is controlled at 1050°C, and the remaining steps and methods are the same as in Example 1. The gas composition obtained is: CO 13.49%, CO 2 17.63%, CH 4 2.49%, O 2 0.57%, H 2 20.1%, C 2 0.64% of the above ingredients, N 2 45.81%; gas calorific value 5.17MJ / m 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com