Multi radiation reqion pyrolyzer and its use

A cracking furnace and radiation zone technology, applied in cracking, non-catalytic thermal cracking, petroleum industry, etc., can solve the problem of reducing the service life of cracking selective cracking furnace, cracking furnace operation cycle and product yield, increasing raw material consumption, energy consumption and Production cost, complex cracking furnace operation control and other issues, to achieve the effect of wide range of raw material adaptability, compact structure, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

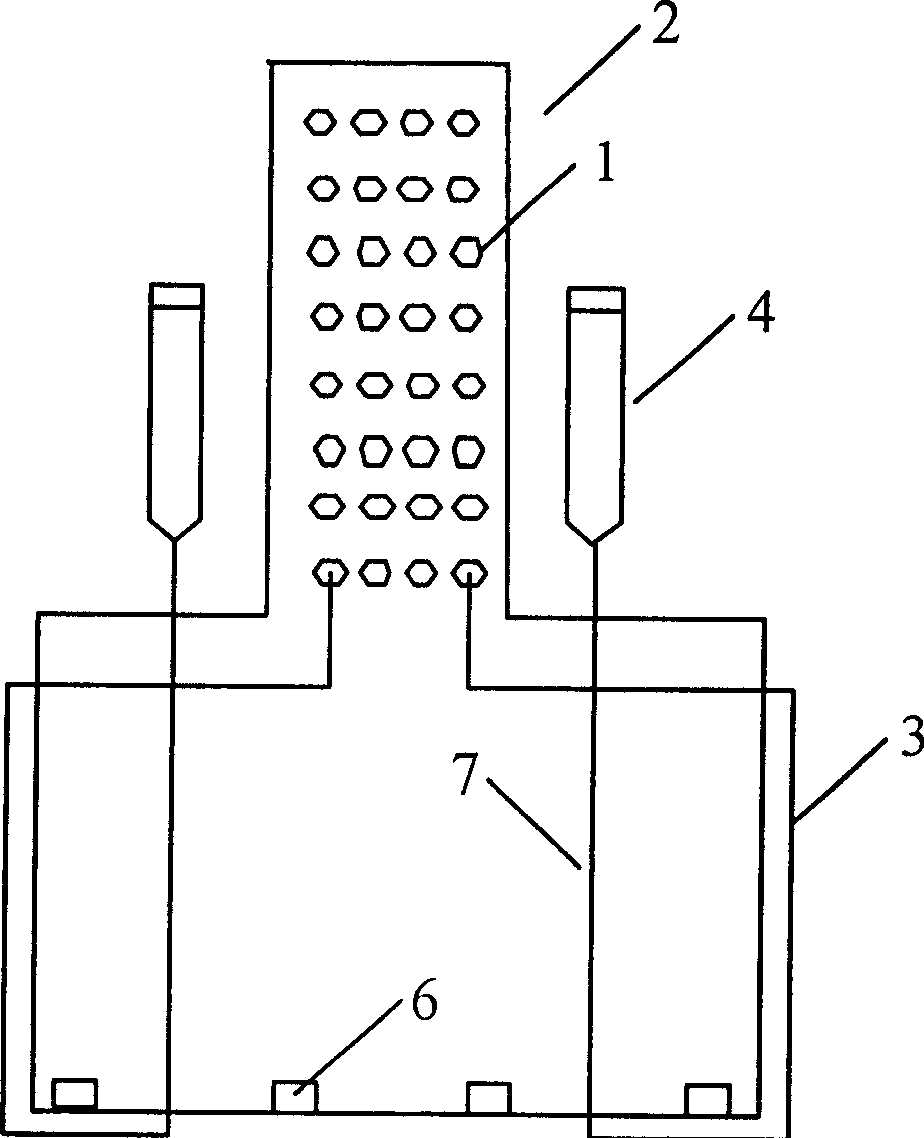

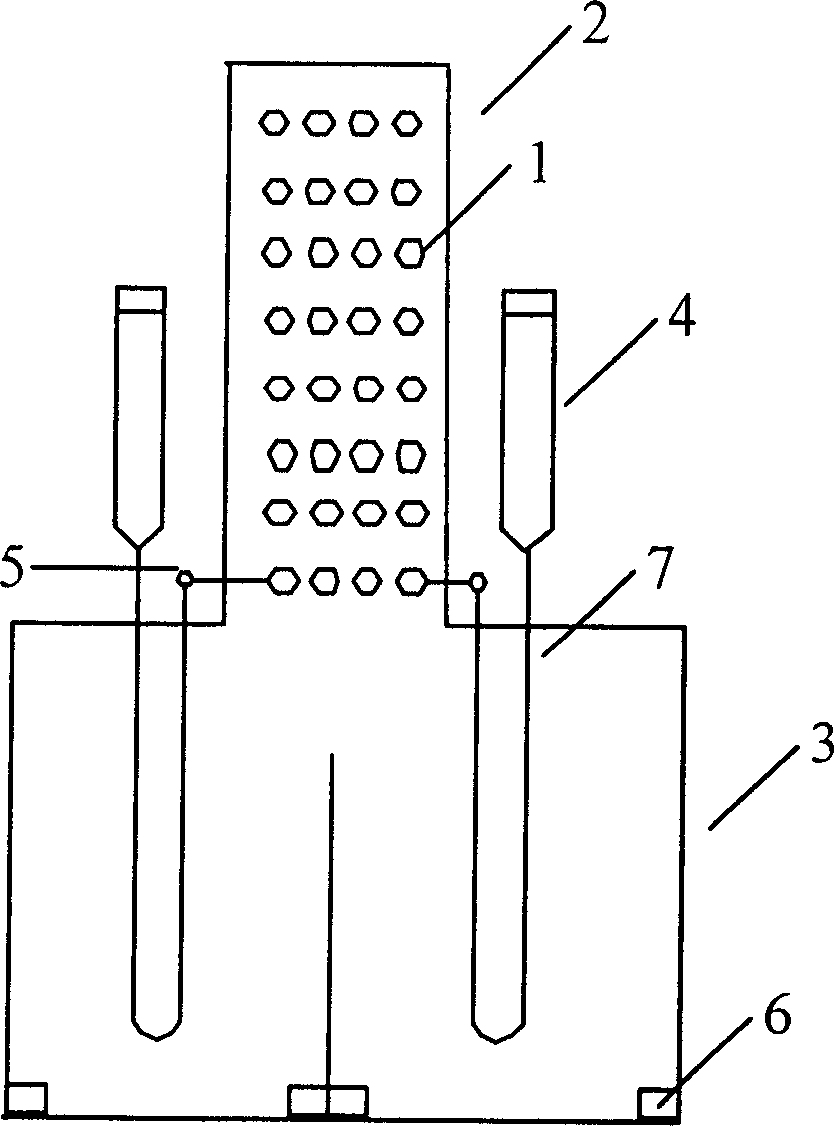

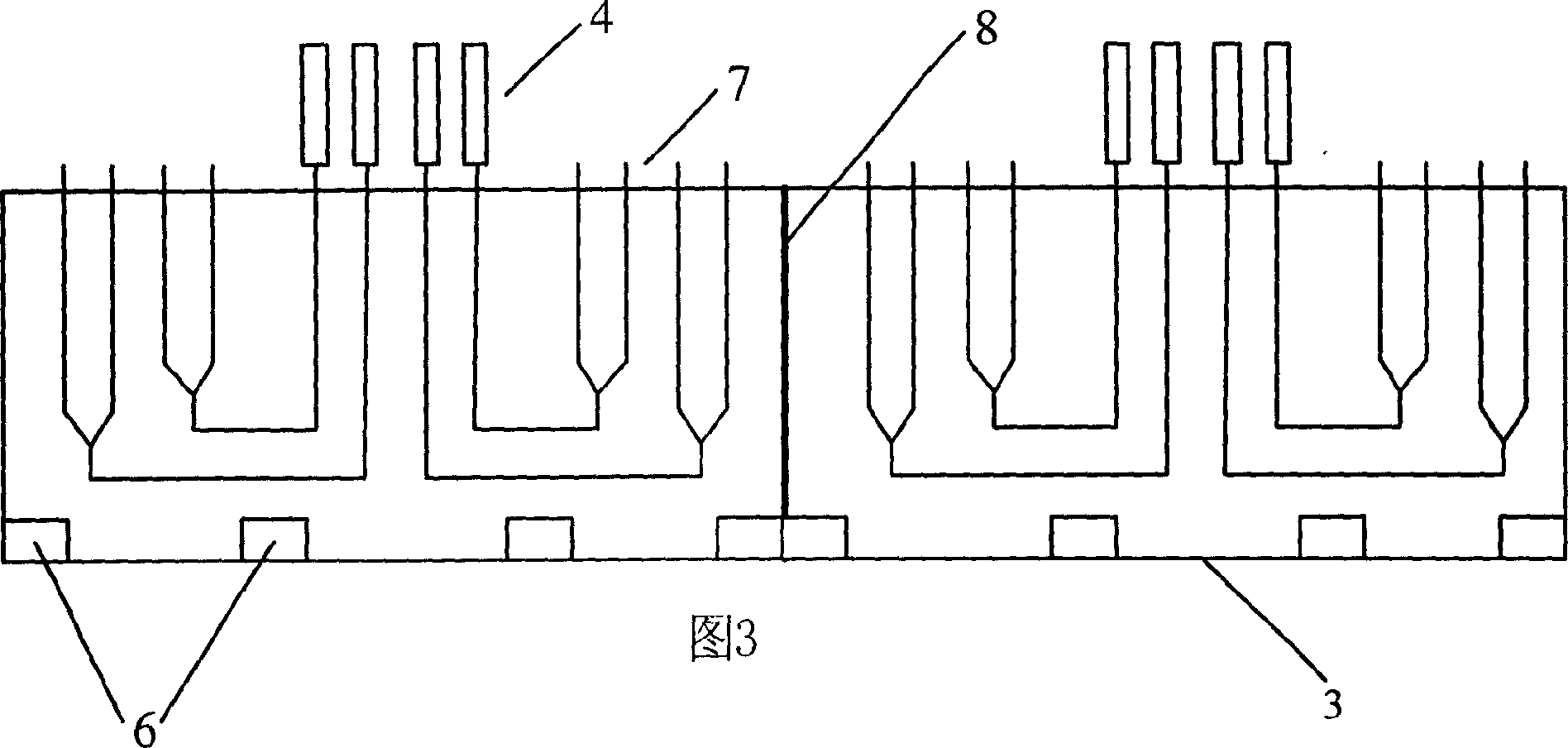

[0042] 1 cracking furnace with an annual output of 300,000 tons. The cracking furnace includes a radiation section 3 with a hearth height of about 17 meters; a convection section 2 with a height of about 15 meters; the radiation section is divided into four radiation areas by intersecting furnace walls; 40 groups of 2-1 are arranged in each radiation area type furnace tube, and 24 bottom burners are arranged symmetrically with the furnace tube as the axis. The four raw materials of ethane, naphtha, diesel and hydrogenated tail oil can be cracked respectively in the four radiation zones. Load 96.55GJ / h; hydrogenated tail oil crossover temperature 561°C, outlet temperature 812°C, heat load in the radiation section 101.50GJ / h; diesel crossover temperature 557°C, outlet temperature 816°C, heat load in the radiation section 100.67GJ / h ; The ethane crossing temperature is 636°C, the outlet temperature is 851°C, and the heat load of the radiant section is 86.24GJ / h. By adjusting th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com