Thermal container

a container and thermal insulation technology, applied in the direction of containers, liquid dispensing, packaged goods, etc., can solve the problem of spoilage of stored materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 2

[0085] A transport container 1 similar to Example 1 is provided, in accordance with the invention, with an insulation flange 48 which tightly and sealingly engages the internal tube or wall 15, the leg 42 and the lip 43 which in the area of the double-sine or S-shaped fillet 36 forms an annular cavity. In the present context, "annular cavity" is intended to connote a chamber similar to a body resulting from moving a planar figure along a closed curve--for instance by revolving about an axis disposed in the plane of the figure without intersecting it. In the embodiment shown in FIG. 6, the figure chosen resembles the segment of a circle limited by one of the curves of the S-shaped fillet 36 and the marginal surface 50 of the insulation flange 48, the rotational axis of the figure being the axis of symmetry of the transport container 1. In accordance with the invention, the annular cavity 49 of the container described need not be shaped like a segment of a circle; it may have other pr...

example 3

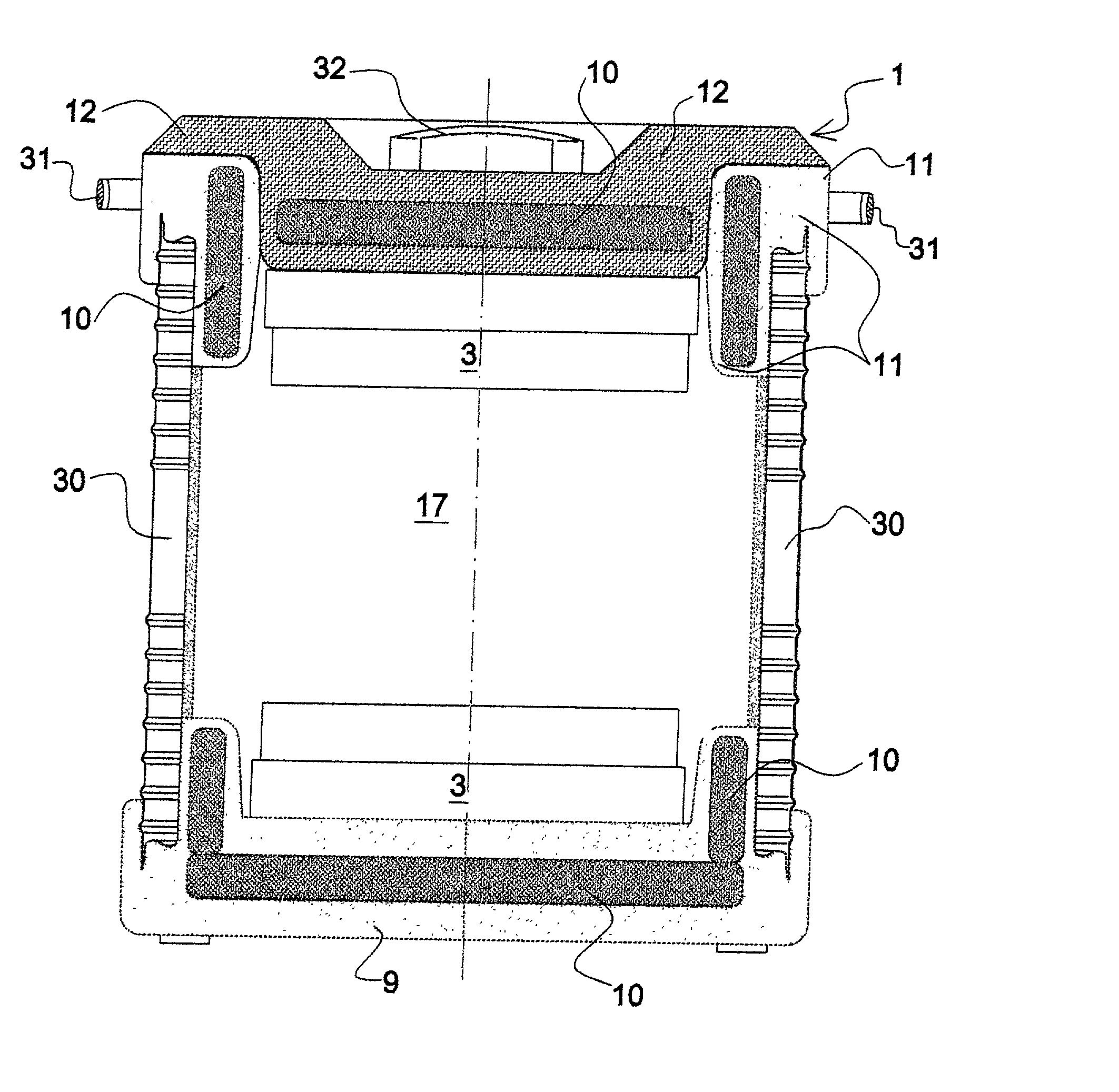

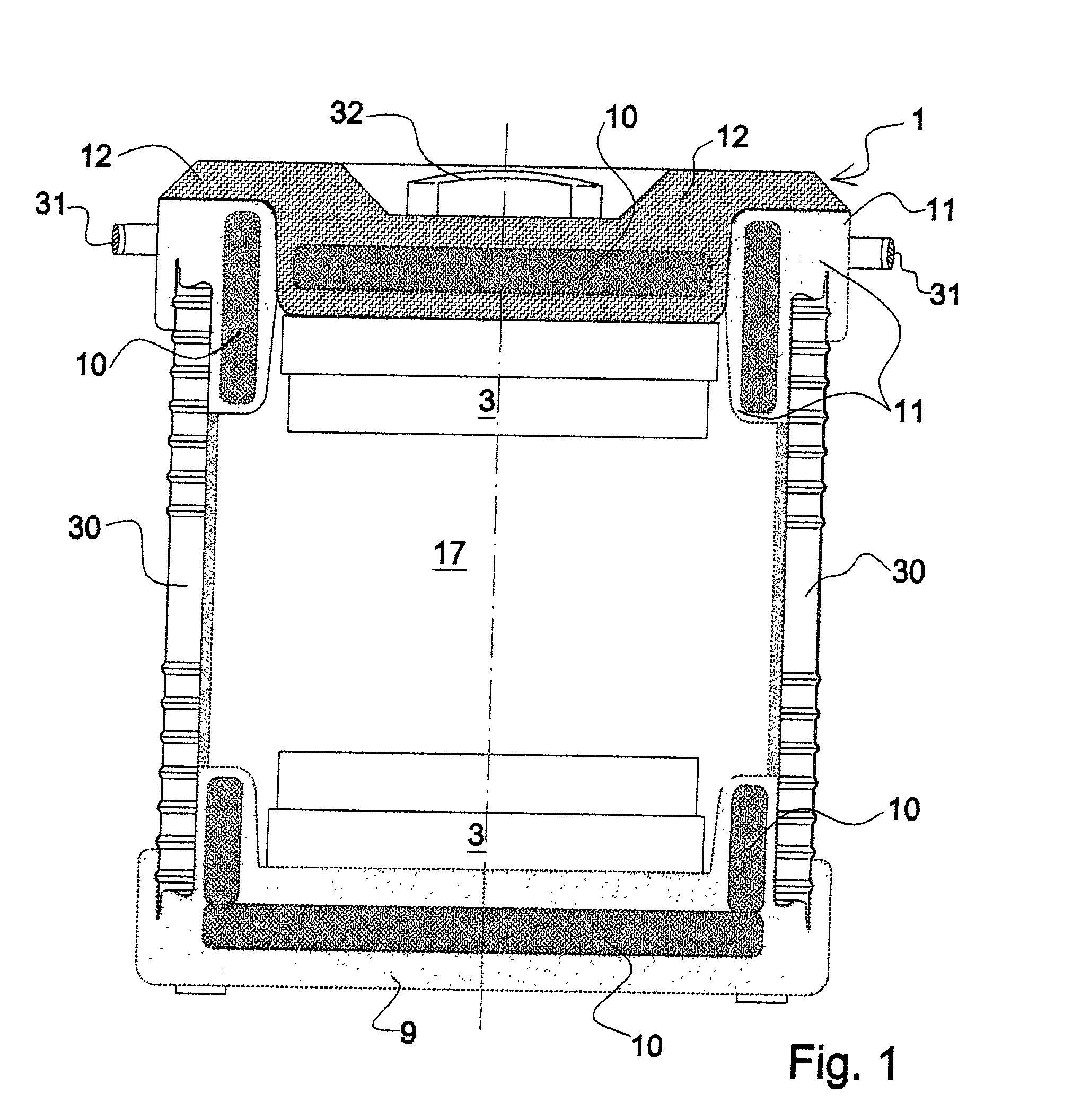

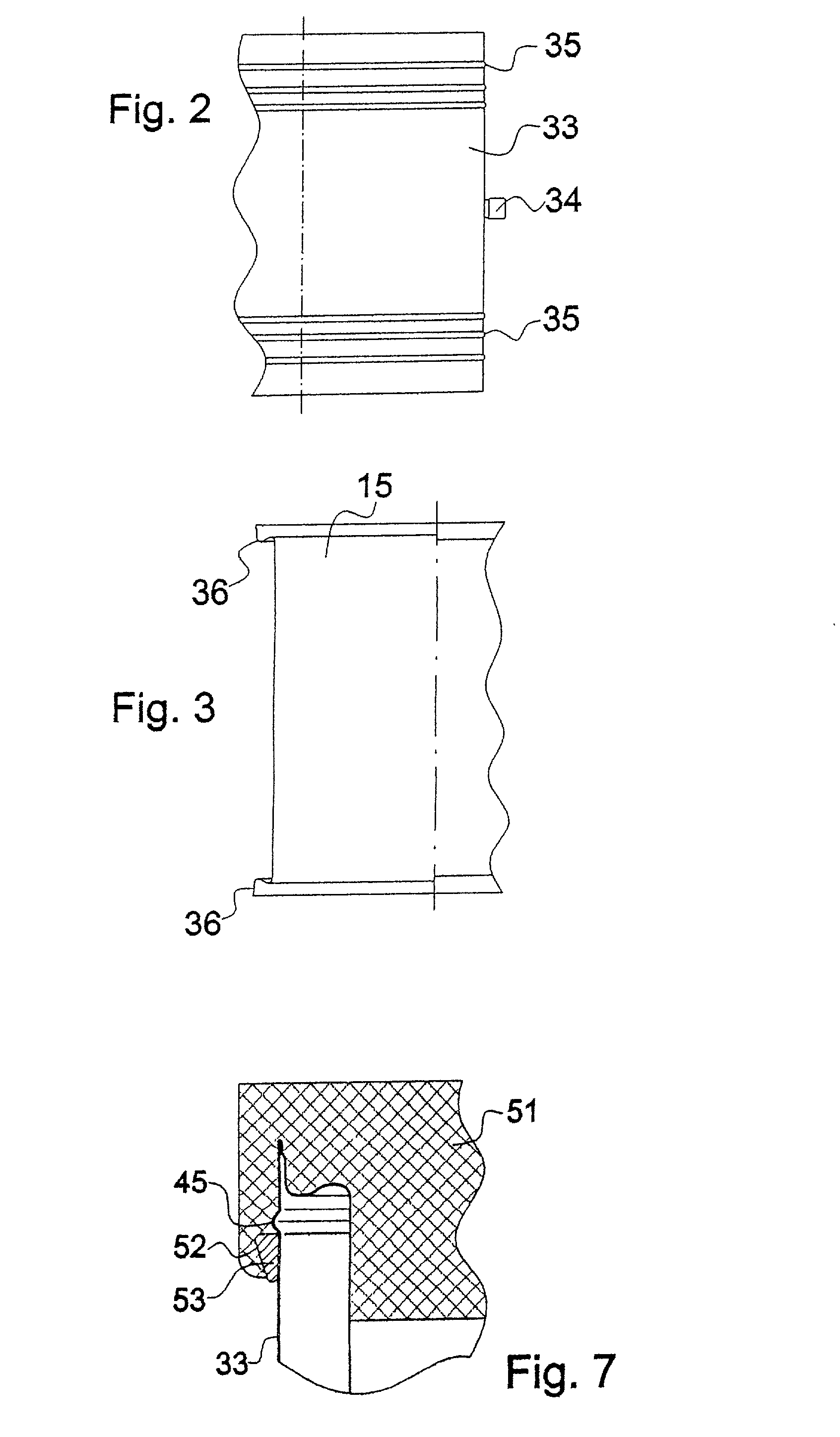

[0090] A transport container 1 substantially similar to that of Example 1 differs structurally at the rim of the openings of the hollow body, i.e. at the connections between its internal tube 15 and its external tube 33. FIG. 7 offers a sectional view of the area of a container rim of the embodiment to be described.

[0091] An annular flange 51 is provided close to the outer circumference of the external tube 33 of the casing 30. A gap 52 in the flange 51 is filled with a suitable adhesive, for instance a silicon adhesive, after the flange 51 has been attached to the casing 30. This results in a particularly sturdy connection between the flange 51 behind the bead 45 in the external wall 33. Such a structure is suitable for closing either end of the tubular hollow body.

example 4

[0092] A transport container 1 generally similar to Example 1 has a differently structured rim at the openings of the hollow body. The transitional zone between its internal tube 15 and its external tube 33 differs as may be seen from the four configurations depicted in FIG. 8. At their top and bottom ends the internal tube 15 and the external tube 33 converge approximately semi-circularly and are joined by a welded seam 44. In addition, the internal tube 15 is provided with outwardly and inwardly directed beads 45 and 54. This results in a reduced material thickness and, hence, provides for a heat path of extended length.

[0093] Three further examples shown in FIG. 8 depict variations of the connections between internal tube 15 and external tube 33. Prior to being joined by the welding seam 44, the two tubes are shaped in different ways. Each one of these variations does ensure at least two degrees of freedom between the tubes and thus accommodates the desired properties of resilien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com