High-purity zirconia insulating refractory product

A technology of refractory products and zirconia, which is applied in the field of refractory materials, can solve the problems of unfavorable energy saving and portability of ultra-high temperature equipment, the influence of the overall structure of the lining material, and the increase of thermal conductivity of the insulation layer, etc., to achieve small crystallization and reduce thermal conductivity rate, improve the effect of thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

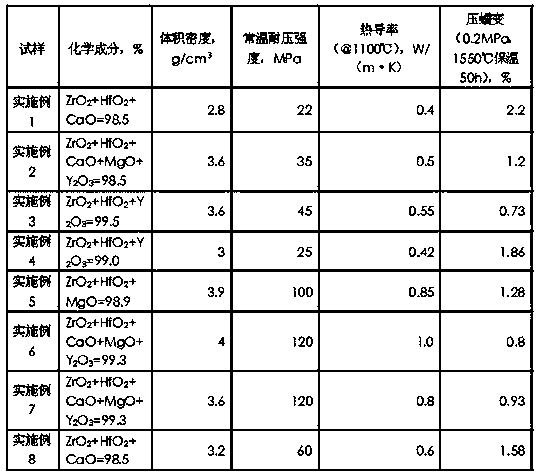

Examples

Embodiment 1

[0027] The chemical composition with a particle size greater than 43 μm and less than or equal to 100 μm was weighed as a purity of w (ZrO 2 +HfO 2 +CaO) ≥ 99.0% fused calcium oxide stabilized zirconia fine powder 35 kg, particle size D 50 The chemical composition of ≤10μm is w (ZrO 2 +HfO 2 ) ≥ 99.5% monoclinic zirconia powder 8 kg, calcium carbonate fine powder with a particle size greater than 43 μm and less than or equal to 100 μm 1 kg, edible wheat flour with a particle size greater than 43 μm and less than or equal to 100 μm 1 kg, fully pre-mixed by a ball mill to prepare matrix fine powder ; Weighing particle size greater than 0.2 mm less than or equal to 3mm, w (ZrO 2 +HfO 2 +CaO)≥98.3%, bulk density 2.8 g / cm 3 55 kg of calcium oxide-stabilized zirconia porous particles prepared by the sintering method were added into a forced mixer and mixed; to the particles, about 4 kg of a binder with a mass fraction of 5% polyvinyl alcohol aqueous solution was added, and a...

Embodiment 2

[0029] The chemical composition with a particle size greater than 43 μm and less than or equal to 100 μm was weighed as a purity of w (ZrO 2 +HfO 2 +Y 2 o 3 ) ≥99.0% fused yttria stabilized zirconia fine powder 30 kg, particle size D 50 The chemical composition of ≤5μm is w (ZrO 2 +HfO 2 ) ≥ 99.5% monoclinic zirconia powder 7 kg, industrial yttrium oxide fine powder with a particle size greater than 43 μm and less than or equal to 74 μm 1 kg, carbon powder with a particle size greater than 43 μm and less than or equal to 74 μm 2 kg, fully pre-mixed by a ball mill to prepare matrix fine powder; Weigh the particle size greater than 0.2mm and less than or equal to 3mm, w (ZrO 2 +HfO 2 +CaO+MgO+Y 2 o 3 )≥98.0%, bulk density 3.6 g / cm 3 60kg of calcium magnesium yttrium composite stabilized zirconia porous particles prepared by the sintering method were added to the forced mixer and mixed; 5kg of binder phenolic resin alcohol solution was added to the pellets, and after...

Embodiment 3

[0031] The chemical composition with a particle size greater than 43 μm and less than or equal to 74 μm was weighed as a purity of w (ZrO 2 +HfO 2 +Y 2 o 3 ) ≥99.3% fused yttria stabilized zirconia fine powder 28 kg, particle size D 50 The chemical composition of ≤2μm is w (ZrO 2 +HfO 2 ) ≥ 99.5% monoclinic zirconia micropowder 5 kg, 2 kg of polyethylene plastic pellets with a particle size greater than 74 μm and less than or equal to 100 μm, fully premixed by a ball mill to prepare a matrix fine powder; weigh the particle size greater than 0.2 mm and less than or equal to 3 mm, w (ZrO 2 +HfO 2 +Y 2 o 3 )≥99.5%, bulk density 3.6 g / cm 3 65 kg of yttria-stabilized zirconia porous particles prepared by the sintering method were added into a forced mixer and mixed; 5 kg of binder phenolic resin alcohol solution was added to the particles, and after stirring, poured into the premixed matrix fine powder, and after fully mixing, Raw material: Vibration pressing machine ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com