Liquid nitrogen storage tank with air pressure type safety protection function

A safety protection, air pressure technology, applied in the field of cryogenic liquid storage equipment, can solve problems such as the expansion of shell cracks, shell cracks, and potential safety hazards for experimenters, and achieve the effect of preventing fatigue detachment, prolonging service life, and improving storage effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

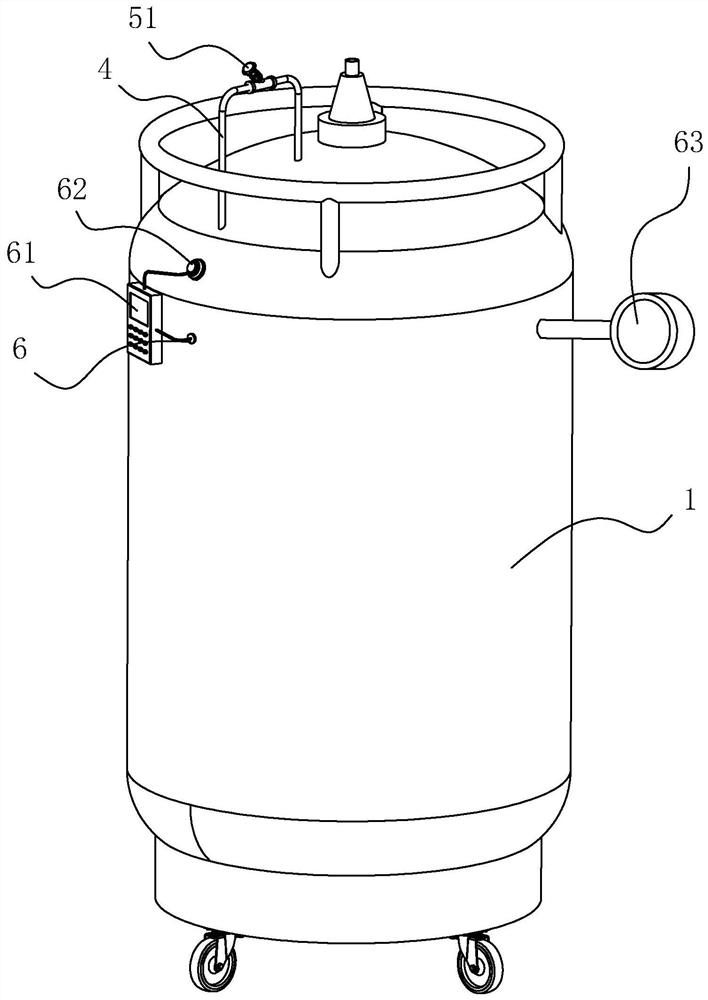

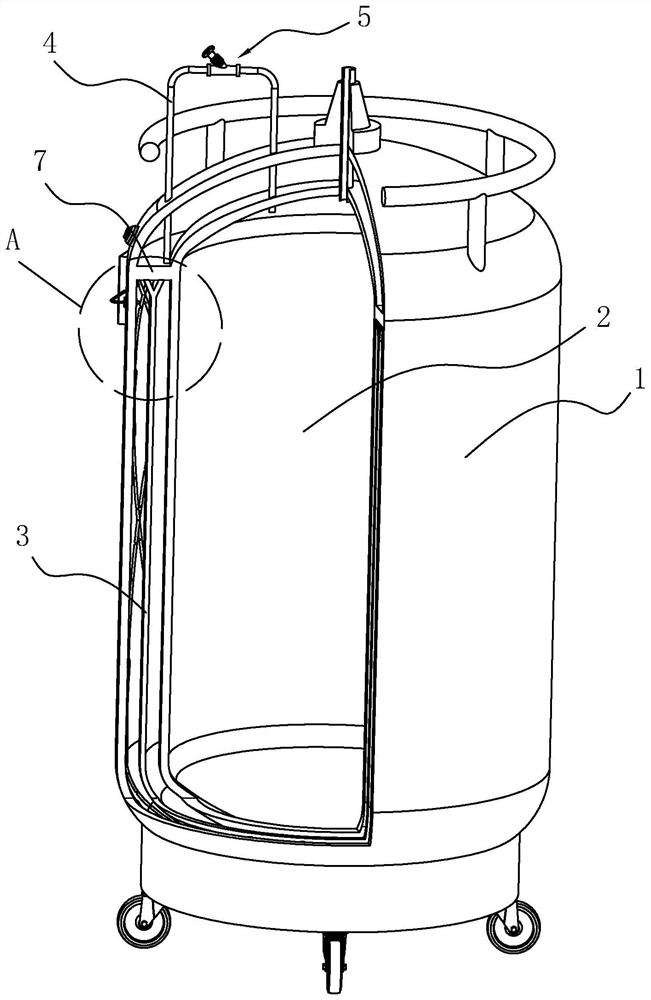

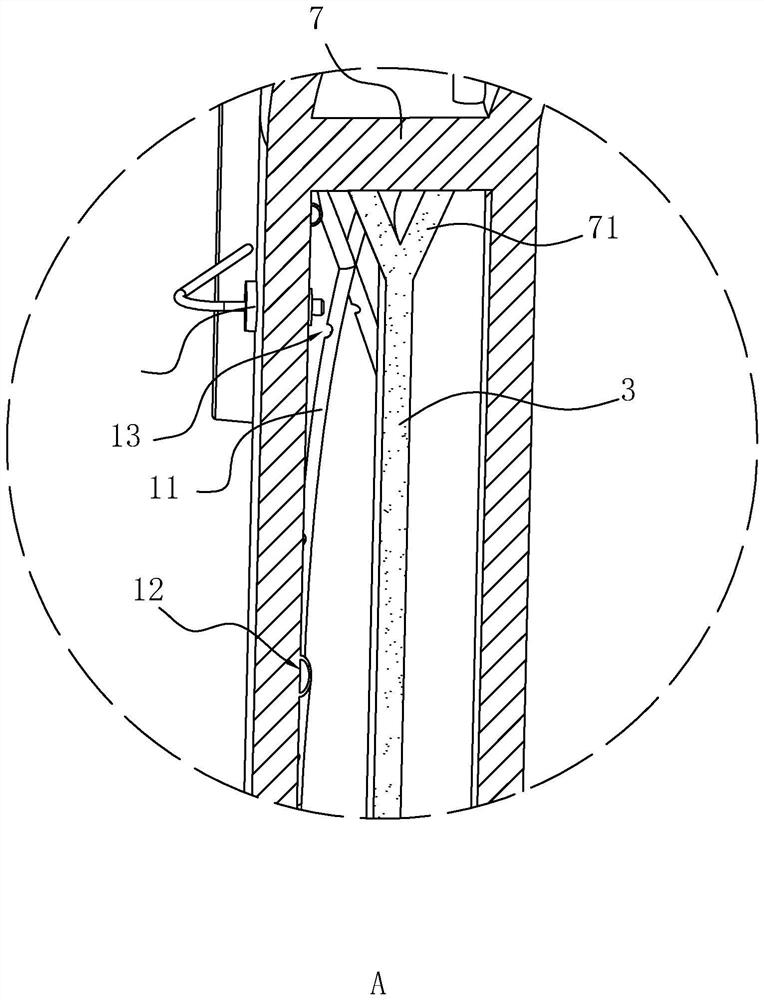

[0040] refer to figure 1 , 2 The storage tank includes an outer shell 1 and an inner tank 2, the inner tank 2 is arranged inside the outer shell 1, and the space between the outer shell 1 and the inner tank 2 is a hollow structure. On the outer wall of the liner 2 near the top of the inner liner 2, a circle of mounting discs 7 is fixed by coaxial welding, and the outer edge of the mounting discs 7 is welded and fixed on the inner wall of the shell 1 near the top. The outer side of the liner 2 is located below the mounting plate 7 and is covered with a protective cover 3 , and the upper opening edge of the protective cover 3 is coaxially fixedly connected with the mounting plate 7 . Before the storage tank is produced, the gap between the shell 1 and the protective cover 3 is filled with high-pressure gas, such as nitrogen, oxygen, and the like.

[0041] refer to figure 1 , 2 , after the cracks in the shell 1 cause the gas between the shell 1 and the protective cover 3 to e...

Embodiment 2

[0050] refer to figure 2 , 5 , The difference between Embodiment 2 and Embodiment 1 lies in: the valve assembly 5 is different.

[0051] In this embodiment, the valve assembly 5 includes a solenoid valve 501 installed on the communication pipe 4 for opening and closing the communication pipe 4 . The solenoid valve 501 is electrically connected to the controller 61. When the air pressure value between the protective cover 3 and the shell 1 is lower than the preset value on the controller 61, the controller 61 controls the solenoid valve 501 to open, so that the inner cavity of the inner tank 2 communicates with the inner cavity. There is a gap between the bile 2 and the protective cover 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com