Method for reducing heat loss of industrial furnace shell

A technology for heat loss and industrial furnaces, which is applied in the field of reducing heat loss of industrial furnaces and reducing heat loss of industrial furnace shells, can solve problems that have not been discovered, achieve high use value, improve energy saving effects, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

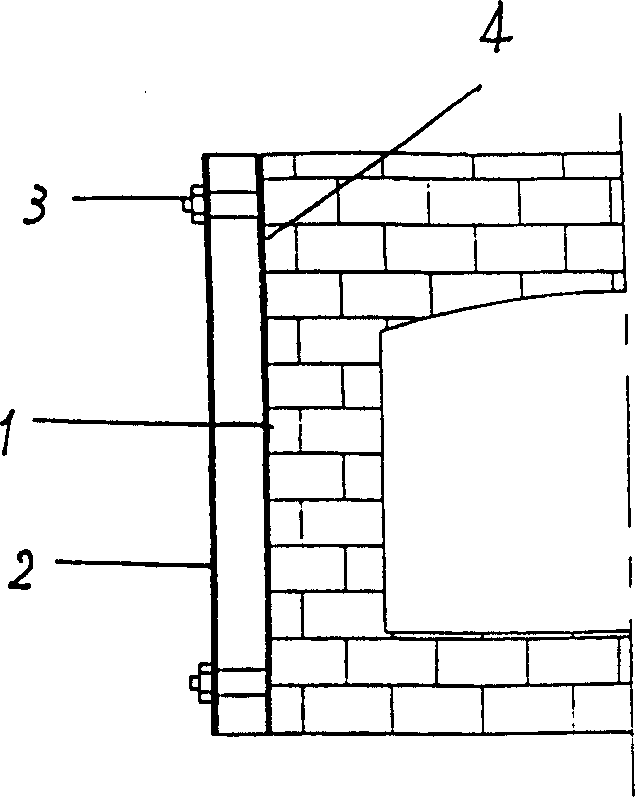

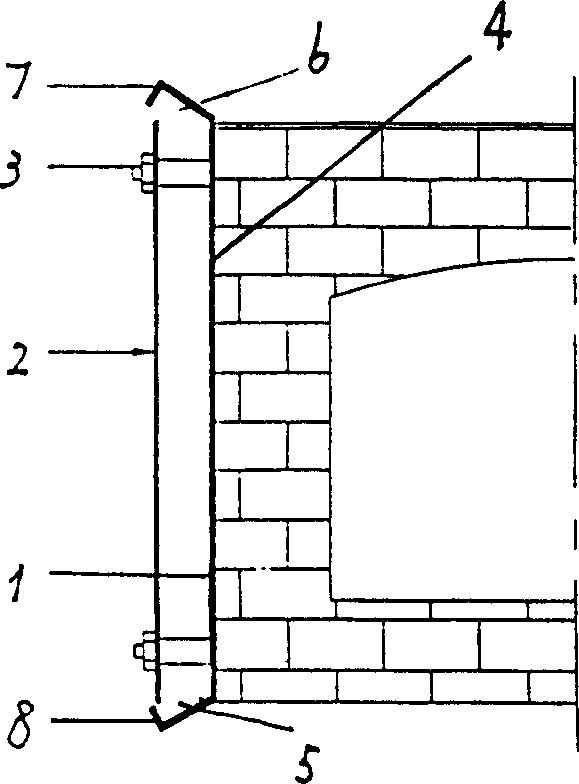

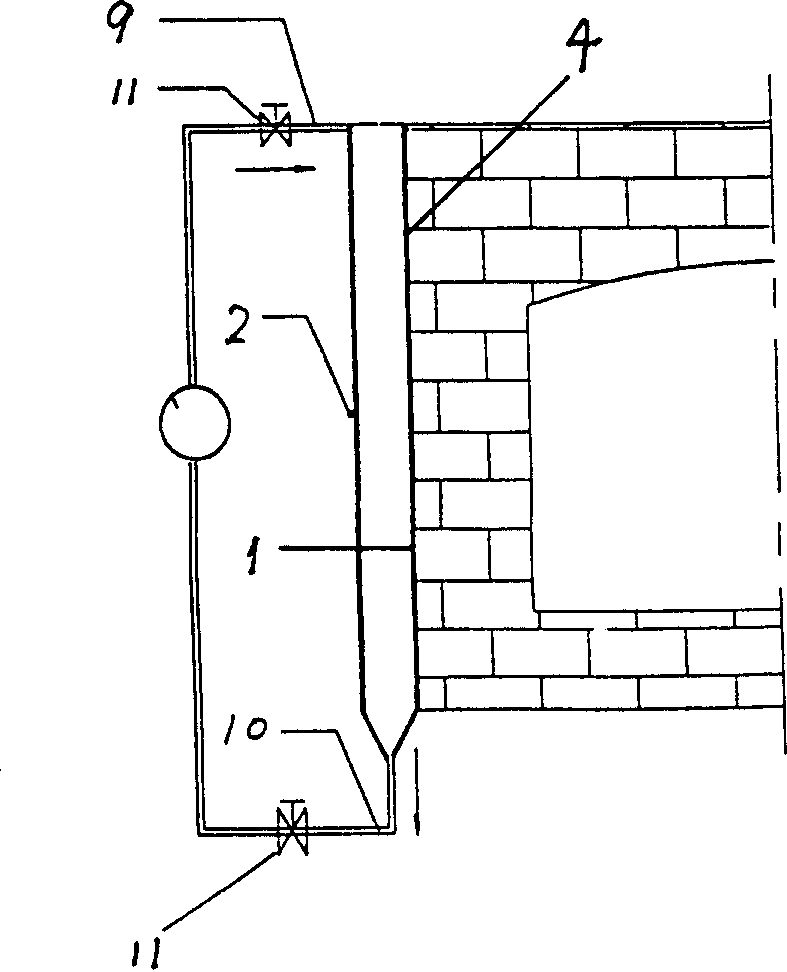

[0011] Such as figure 1 , figure 2 , image 3 As shown in Figure 4, the present invention adopts the method of double-layer furnace shell structure, and a layer of thin steel plate or aluminum plate 2 is installed outside the furnace shell 1, and the closed air layer formed increases the thermal resistance, forming a double-layer furnace shell, two layers The bolts 3 of the porcelain tubes or other methods can be used to connect between them, the surface temperature of the furnace is further reduced to reduce heat loss, and a layer of refractory fiber 4 can also be pasted on the inside or outside of the double-layer furnace shell, and the effect is better. Movable cover plates 7, 8 are installed on the bottom 5 and the top 6 of the double-layer furnace shell. When heating and heat preservation, the upper cover 7 and the lower cover 8 are closed, and the double-layer furnace shell forms a closed air layer to reduce heat loss. Open the upper and lower covers 7 and 8 during co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com