Environment-friendly humidifying diatom ooze coating

A diatom mud coating and diatom mud technology, applied in the coating and other directions, can solve the problems of limited air purification ability and insignificant humidity control effect, so as to improve hiding power, improve formaldehyde purification performance, and improve formaldehyde purification durability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

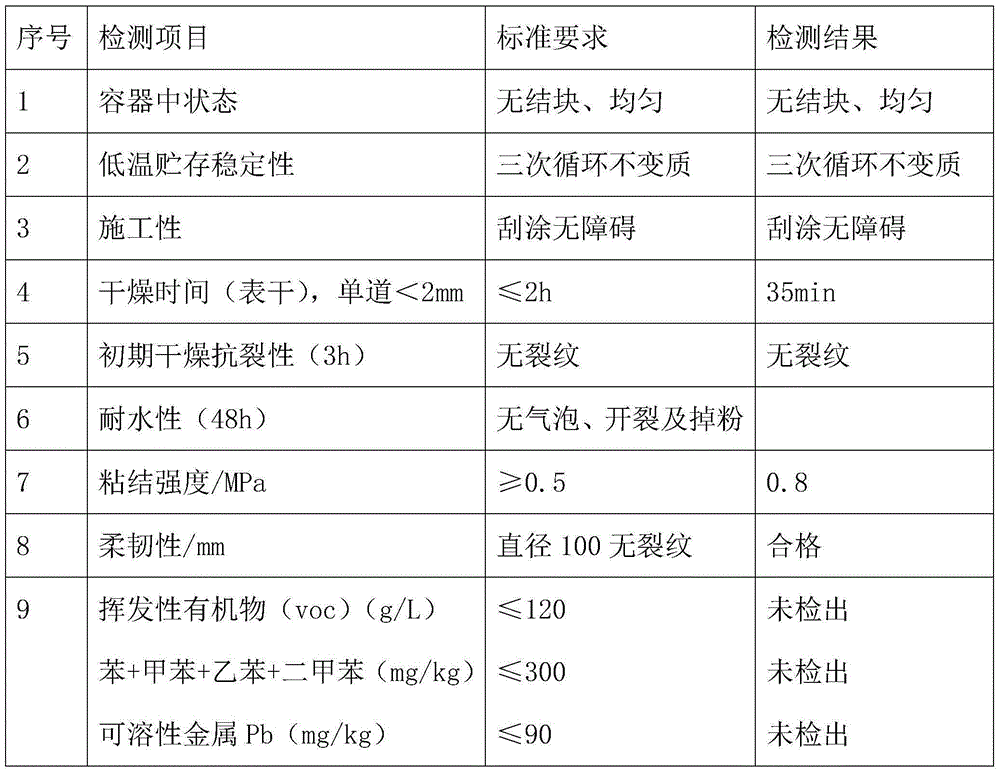

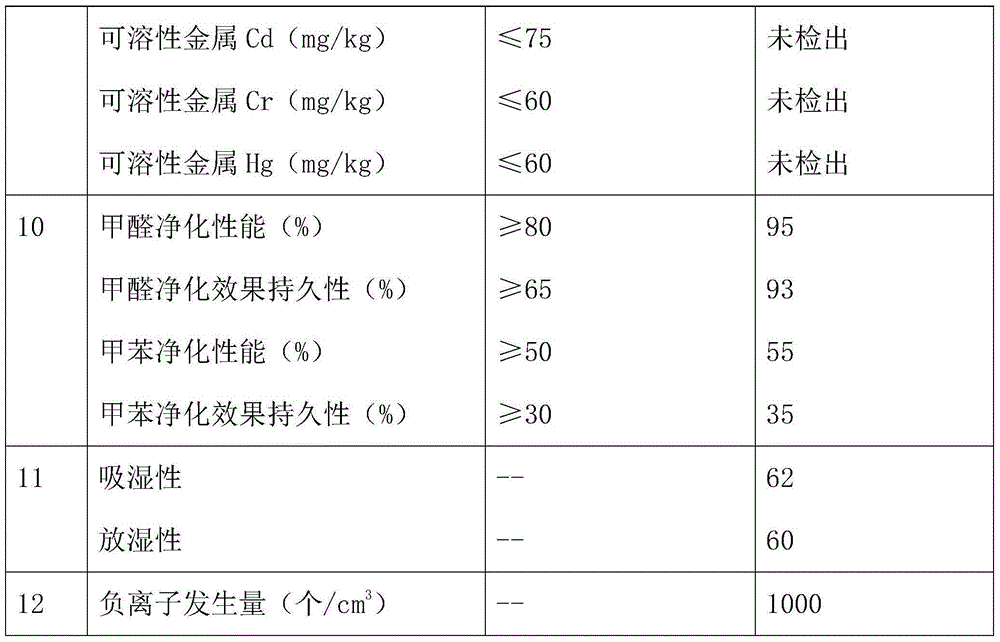

Examples

Embodiment 1

[0018] In this embodiment, an environmentally friendly and humidity-adjusting diatom mud coating, its raw materials include by weight: 40 parts of silica sol / styrene-acrylic compound emulsion, 20 parts of pure acrylic emulsion, 35 parts of modified diatom mud, light carbonic acid 15 parts of calcium, 3 parts of lithopone, 10 parts of negative ion powder, 0.1 part of sodium alginate, 0.3 parts of dispersant SN-5040, 3 parts of ethylene glycol, 0.5 parts of wetting agent AP-6800, 0.4 parts of alcohol ester twelve, propylene glycol 0.3 parts of methyl ether acetate, 0.5 parts of thickener, 0.4 parts of leveling agent, 0.2 parts of defoamer, 0.1 part of bactericidal antifungal agent, 65 parts of deionized water;

[0019] The preparation process of the silica sol / styrene-acrylic composite emulsion comprises: 10 parts by weight of silica sol, 0.2 parts of sodium dodecylsulfonate, 0.1 parts of wetting agent X-4050 and 1 part of silane coupling agent KH-5601 After stirring and mixing,...

Embodiment 2

[0023] In this embodiment, an environmentally friendly and humidity-adjusting diatom mud coating, its raw materials include by weight: 56 parts of silica sol / styrene-acrylic compound emulsion, 10 parts of pure acrylic emulsion, 45 parts of modified diatom mud, light carbonic acid 8 parts of calcium, 6 parts of lithopone, 5 parts of negative ion powder, 0.3 parts of sodium alginate, 0.1 parts of dispersant SN-5040, 5 parts of ethylene glycol, 0.3 parts of wetting agent AP-6800, 0.6 parts of alcohol ester twelve, propylene glycol 0.1 part of methyl ether acetate, 1 part of thickener, 0.2 part of leveling agent, 0.4 part of defoamer, 0.01 part of bactericidal antifungal agent, 80 parts of deionized water;

[0024] The preparation process of the silica sol / styrene-acrylic compound emulsion comprises: 20 parts by weight of silica sol, 0.1 part of sodium dodecylsulfonate, 0.2 parts of wetting agent X-4050 and 0.5 parts of silane coupling agent KH-5600. After stirring and mixing, let...

Embodiment 3

[0028] In this embodiment, an environment-friendly and humidity-adjusting diatom mud coating, its raw materials include by weight: 48 parts of silica sol / styrene-acrylic compound emulsion, 15 parts of pure acrylic emulsion, 40 parts of modified diatom mud, light carbonic acid 11 parts of calcium, 4 parts of lithopone, 7 parts of negative ion powder, 0.2 parts of sodium alginate, 0.2 parts of dispersant SN-5040, 4 parts of ethylene glycol, 0.4 parts of wetting agent AP-6800, 0.5 parts of alcohol ester twelve, propylene glycol 0.2 parts of methyl ether acetate, 0.7 parts of thickener, 0.3 parts of leveling agent, 0.3 parts of defoamer, 0.05 parts of bactericidal antifungal agent, 70 parts of deionized water;

[0029] The preparation process of the silica sol / styrene-acrylic composite emulsion comprises: 15 parts by weight of silica sol, 0.15 parts of sodium dodecylsulfonate, 0.15 parts of wetting agent X-4050 and 0.7 parts of silane coupling agent KH-5600. After stirring and mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com