Biodiesel catalyst and method for preparing biodiesel by using same

A biodiesel and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., can solve the problem of high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

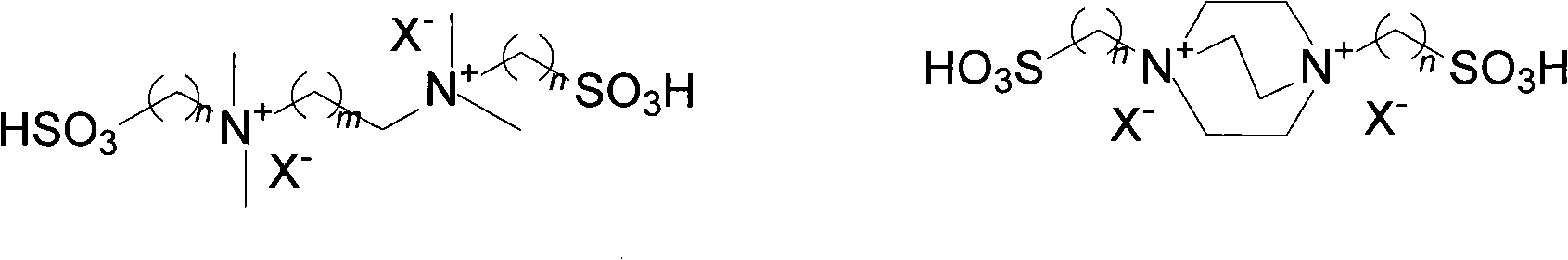

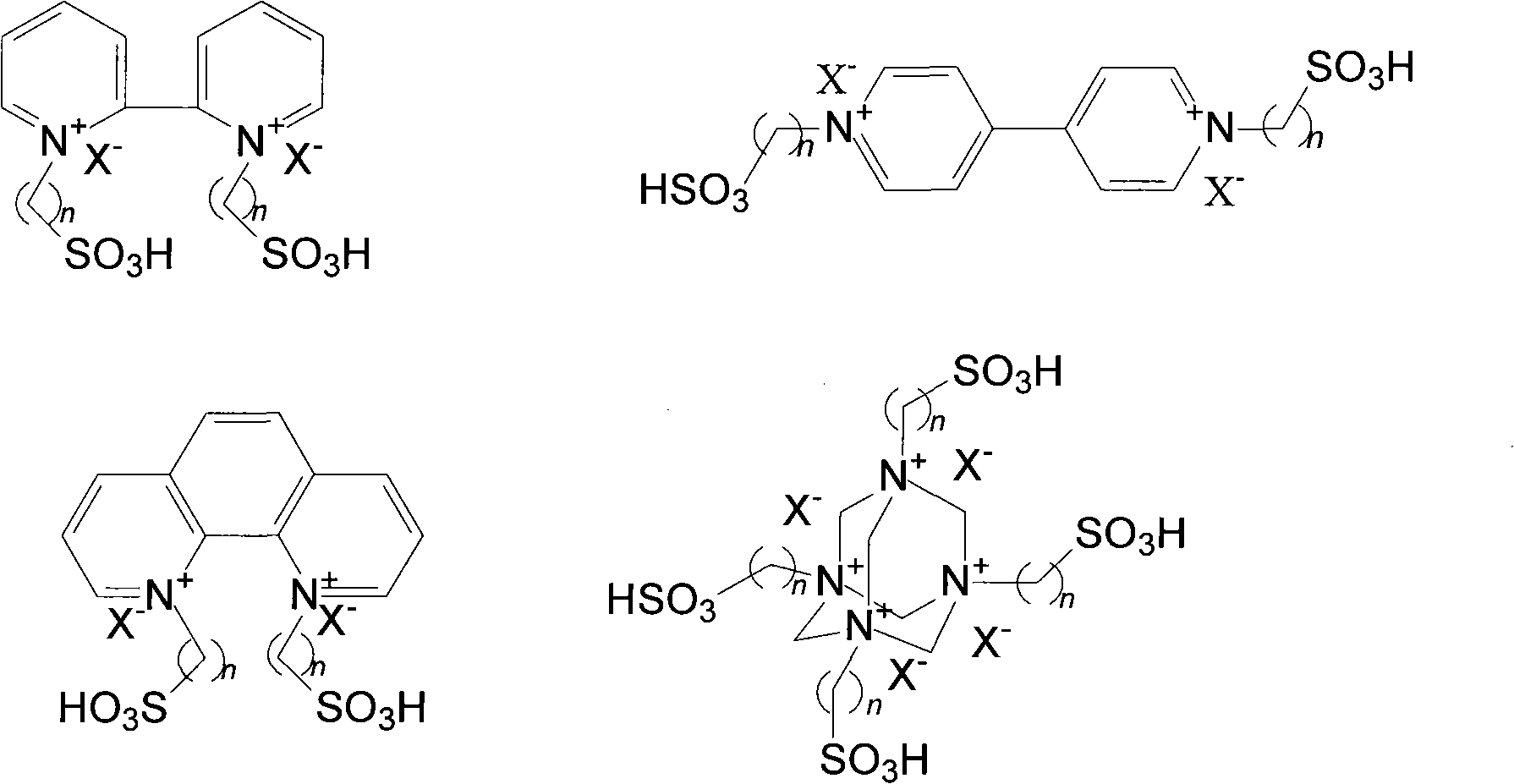

Method used

Image

Examples

Embodiment 1

[0064] Catalyzed esterification of oleic acid with tetrasulfonic acid functionalized urotropine bisulfate ionic liquid to prepare biodiesel

[0065] 1. Preparation of Tetrasulfonic Acid Functionalized Urotropine Bisulfate Ionic Liquid

[0066] A) Dissolve one equivalent of urotropine and four equivalents of 1,4-butane sultone in toluene, heat to 80°C, and keep stirring at 80°C until there is no more white precipitate, react After the system was cooled, it was filtered, and the precipitate was washed with toluene, and then dried at 80°C under a relative vacuum of -0.095MPa to obtain a white inner salt with a yield of 99.0%;

[0067] B) Dissolve the white internal salt in water, add concentrated sulfuric acid dropwise while stirring at room temperature (20°C), stir evenly, and react for 2 hours, then evaporate and remove water at 60°C under the condition of relative vacuum of -0.095MPa, Promptly obtain a kind of clear liquid that is liquid at room temperature, N', N", N"', N""-...

Embodiment 2

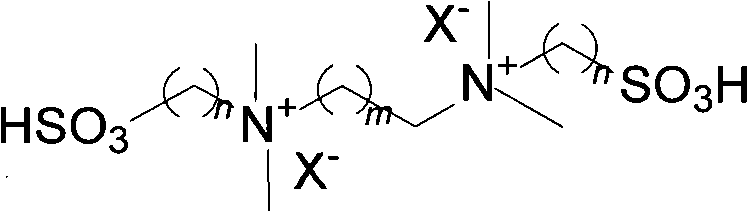

[0074] Disulfonic acid-functionalized N,N,N′,N′-tetramethylethylenediamine bisulfate ionic liquid catalyzed esterification of oil to biodiesel

[0075] 1. Preparation of disulfonic acid functionalized N,N,N',N'-tetramethylethylenediamine hydrogensulfate ionic liquid

[0076] A) Dissolve one equivalent of N, N, N', N'-tetramethylethylenediamine and two equivalents of 1,4-butane sultone in toluene, heat to 80°C, and Stir continuously until there is no more white precipitate, filter the white precipitate, wash the precipitate with toluene, and then dry at 80°C under a relative vacuum of -0.095MPa to obtain a white inner salt with a yield of 99.5%;

[0077] B) Dissolve the white internal salt in water, add concentrated sulfuric acid dropwise while stirring at room temperature (20°C), stir evenly, and react for 2 hours, then evaporate and remove water at 60°C under the condition of a relative vacuum of -0.095MPa, namely Obtain a liquid clear liquid at room temperature, that is, N,...

Embodiment 3

[0082] Disulfonic acid functionalized triethylenediamine bisulfate ionic liquid catalyzed esterification of oil to biodiesel

[0083] 1. Preparation of disulfonic acid functionalized triethylenediamine bisulfate ionic liquid

[0084] A) Dissolve one equivalent of triethylenediamine and two equivalents of 1,4-butane sultone in toluene, heat to 80°C, and keep stirring at 80°C until there is no more white precipitate. The white precipitate was filtered, washed with toluene, and then dried at 80°C under a relative vacuum of -0.095MPa to obtain a white inner salt with a yield of 99.1%;

[0085] B) Dissolve the white internal salt in water, add concentrated sulfuric acid dropwise while stirring at room temperature (15°C), stir evenly, and react for 2 hours, then evaporate and remove water at 60°C under the condition of relative vacuum of -0.095MPa, namely Obtain a kind of clear liquid that is liquid at room temperature, promptly get N, N '-dibutanesulfonic acid group-triethylenedia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com