Capacitor battery with high safety

A capacitor battery, high-safety technology, applied in the field of electrochemistry, can solve the problems of accelerated oxidation of electrolyte, battery thermal runaway, battery overcharge, etc., and achieves the effect of high electrochemical window, low vapor pressure, and improved safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

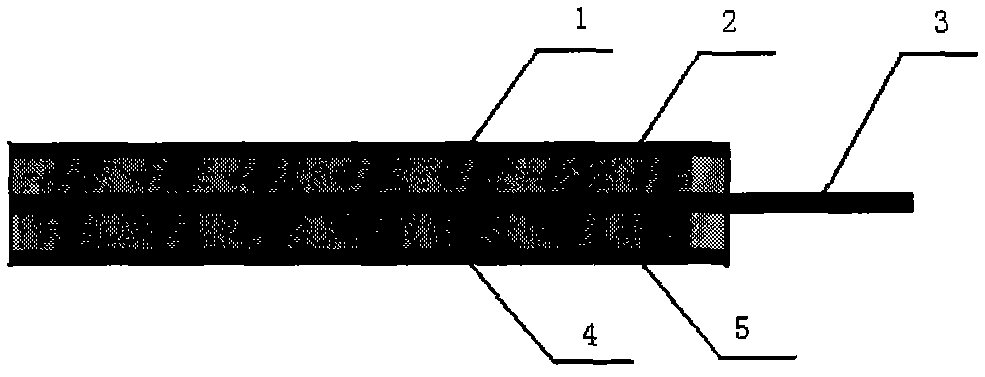

Image

Examples

Embodiment 1

[0016] Positive electrode sheet production: put commercialized nickel-cobalt lithium manganese oxide, activated carbon, carbon fiber, and polyvinylidene fluoride in a mass percentage of 80:12:3:5 in a blender with a total amount of 1000 g, and slowly add solvent NMP to carry out Mix the slurry, after the powder and the solvent are fully mixed, the prepared slurry is evenly coated on both sides of the 16 micron aluminum foil, dried, and then rolled and compacted with a pair of rollers. The compacted pole piece is subjected to surface protection coating treatment, and a 1 micron aluminum oxide coating is applied to the positive pole piece, and then dried and cut into pieces to make a positive pole piece for future use.

[0017] Negative electrode sheet production: Accurately measure mesocarbon microspheres, carbon nanotubes, conductive graphite, and polyvinylidene fluoride with a total amount of 1000 g according to 85:5:4:6, and slowly add them to the container and mix them. Slo...

Embodiment 2

[0020] Positive plate production: put the commercialized lithium manganate, carbon nanotubes, conductive graphite, and polyvinylidene fluoride with a total amount of 1000 g in a stirrer at a mass percentage of 80:12:3:5, and slowly add the solvent NMP Carry out slurry mixing, after the powder and solvent are fully mixed, the prepared slurry is evenly coated on both sides of 16 micron aluminum foil, dried, and then rolled and compacted with a pair of rollers. The compacted pole piece is subjected to surface protection coating treatment, and a 0.5 micron aluminum oxide coating is applied to the positive pole piece, then dried and cut into pieces to make a positive pole piece for future use.

[0021] Negative electrode sheet production: Measure the mesocarbon microspheres, activated carbon, conductive graphite, and polyvinylidene fluoride with a total amount of 1000g accurately according to 85:5:4:6 and slowly add them to the container. After mixing, slowly add The solvent NMP is...

Embodiment 3

[0024] Positive electrode sheet production: put the commercialized lithium manganate, activated carbon, conductive graphite, and polyvinylidene fluoride with a total amount of 1000 g in a blender at a mass percentage of 80:12:3:5, and slowly add the solvent NMP for synthesis. After the powder and the solvent are fully mixed, the prepared slurry is evenly coated on both sides of the 16-micron aluminum foil, dried, and then rolled and compacted with a pair of rollers. The compacted pole piece is subjected to surface protection coating treatment, and a 0.3 micron aluminum oxide coating is applied to the positive pole piece, and then dried and cut into pieces to make a positive pole piece for future use.

[0025] Negative electrode sheet production: Accurately measure mesocarbon microspheres, carbon nanotubes, conductive graphite, and polyvinylidene fluoride with a total amount of 1000 g according to 85:5:4:6, and slowly add them to the container and mix them. Slowly add the solve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com