Method for synthesizing biologic diesel oil based on ion liquid

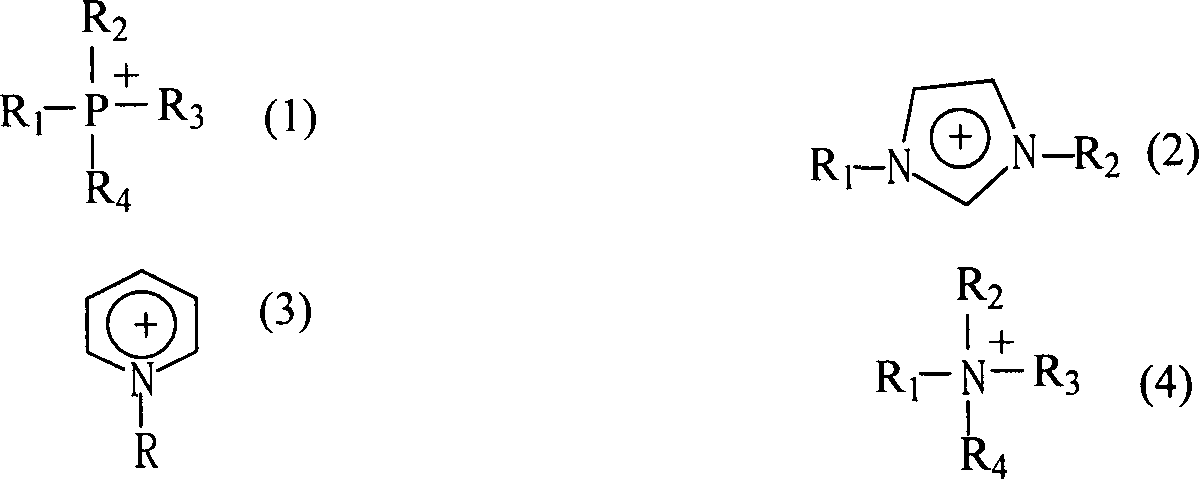

An ionic liquid and biodiesel technology, applied in renewable energy and green fields, can solve problems such as large gaps, and achieve the effect of environmental friendliness and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Synthesis of Biodiesel Catalyzed by Basic Ionic Liquids

[0015] The ionic liquid used is [emim][OH]

[0016] Reaction implementation method: 20g (about 0.023mol) of soybean oil was added to a 50mL clean and dry three-neck round bottom flask, preheated in an oil bath at 60°C, and at the same time, 4.4g of anhydrous analytically pure methanol (about 0.138mol) Mix well with 0.2g [emim][OH] ionic liquid and reflux in an oil bath to preheat to 60°C, then quickly add it into a three-neck round bottom flask, control the temperature at 60±0.1°C, react for 1h, the results are listed in Table 1 .

[0017] Reaction temperature / ℃

Embodiment 2

[0019] Catalytic synthesis of biodiesel by alkaline ionic liquid and other bases

[0020] The catalytic system used is [emim][OH]+NaOH

[0021] Reaction implementation method: 20g (about 0.023mol) of soybean oil was added to a 50mL clean and dry three-neck round bottom flask, preheated in an oil bath at 60°C, and at the same time, 4.4g of anhydrous analytically pure methanol (about 0.138mol) Mix well with 0.1g [emim][OH] and 0.1g NaOH and preheat it to 60°C in an oil bath, then quickly add it into a two-neck round bottom flask, control the temperature at 60±0.1°C, and react for 50min, the results are listed in Table 2.

[0022] Reaction temperature / ℃

Embodiment 3

[0024] Synthesis of Biodiesel Catalyzed by Acidic Ionic Liquid

[0025] The ionic liquid is [bmim][HSO 4 ]

[0026] Reaction implementation method: Add 20g (about 0.023mol) soybean oil and 10.72g anhydrous analytical pure methanol (about 0.46mol) into a 125mL clean and dry three-neck round bottom flask, preheat it in an oil bath at 80°C, and at the same time Mix 4.0g of anhydrous analytically pure methanol (to reduce the viscosity of the ionic liquid) with 2g of [bmim][HSO 4 ] The ionic liquid was fully mixed and preheated to 60°C, then quickly added to a three-necked round-bottomed flask, controlled at 80±0.1°C, and reacted for 20 hours. The results are listed in Table 3.

[0027] Reaction temperature / ℃

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com