Patents

Literature

43results about How to "Increase the amorphous region" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing acetate starch with mechanical activation solid phase reaction

The invention discloses a method for preparing acetate starch with mechanical activation solid phase reaction, comprising the following steps: a, mixing acetic anhydride equivalent to 40-80% of starch mass with starch, then adding solid sodium hydroxide equivalent to 1.0-4.0% of starch mass, stirring uniformly and then sealing for placing for 12-36h; b, loading a mixture obtained in the step a in a self-made ball-stirring mill, adding a ball milling medium with a ball material volume ratio of (6-12): 1, wherein the diameter of the ball milling medium is 4-8mm, stirring reaction lasts 40-80 min at the temperature of 40-80 DEG C, and the rotating speed of strirrer is 200-500 rpm; and c, separating the product with the ball milling medium, washing with ethanol with the volume fraction of 60-90% till the pH value is 6.0-7.0, vacuumizing and filtering, drying at the temperature of 30-60 DEG C, and then crashing till 100-120 meshed. According to the method, the acetate starch with high substitution value can be prepared, and the technology is simple and environmentally-friendly.

Owner:YULIN NORMAL UNIVERSITY +1

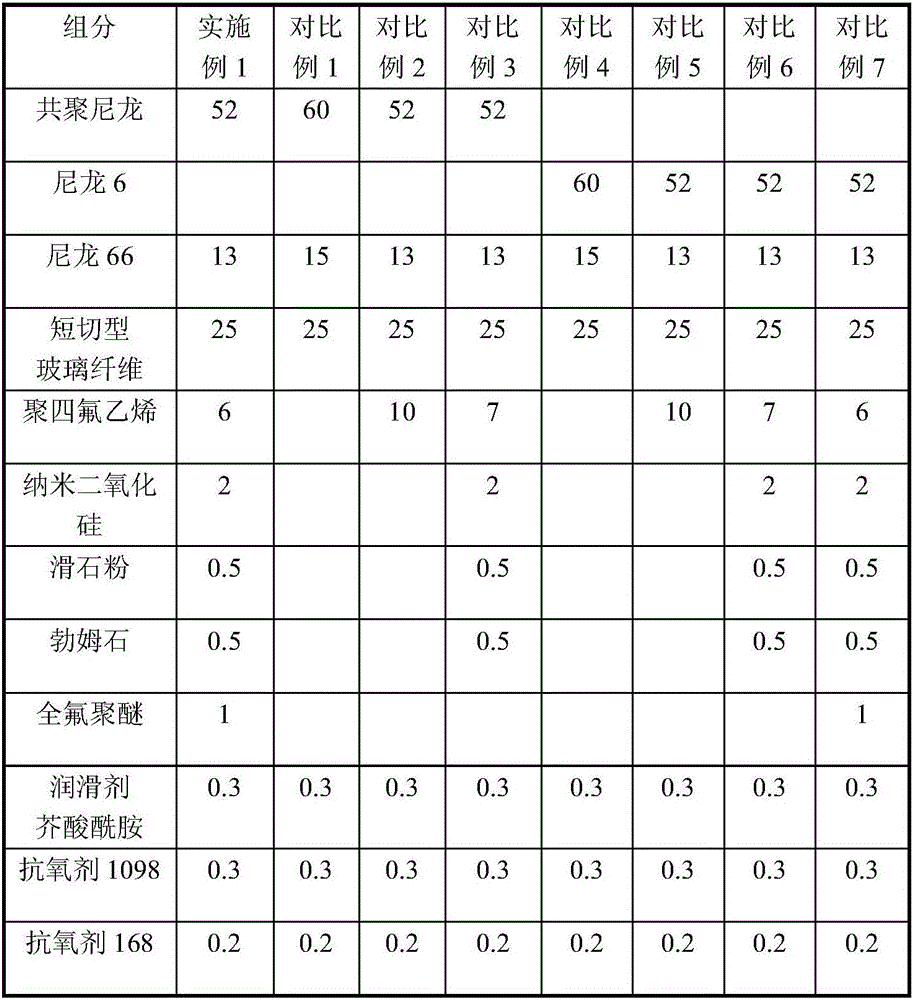

Wear-resistant high-impact-resistance nylon composite material, and preparation method and application thereof

The invention relates to a wear-resistant high-impact-resistance nylon composite material which comprises the following components in parts by weight: 20-80 parts of nylon resin, 10-50 parts of fiber material, 10-40 parts of anti-wear agents, 0.1-2 parts of surface treating agent perfluoropolyether, 0.1-1.0 part of lubricant and 0.1-0.6 part of antioxidant. The preparation method comprises the following steps: uniformly mixing different types of anti-wear agents at medium speed; heating to 90-100 DEG C, adding the perfluoropolyether, and uniformly mixing at high speed; adding the nylon resin, lubricant and antioxidant, and continuing mixing uniformly; and carrying out melt blending extrusion, drawing, cooling, and granulation on the obtained mixture and fiber material through a double screw extruder, thereby obtaining the wear-resistant high-impact-resistance nylon composite material. The wear-resistant high-impact-resistance nylon composite material has the advantages of low friction factor, favorable wear resistance, high mechanical strength, favorable heat resistance, excellent toughness, excellent impact resistance, low mold shrinkage rate, favorable dimensional stability, favorable flowability and high processability.

Owner:株洲时代工程塑料实业有限公司

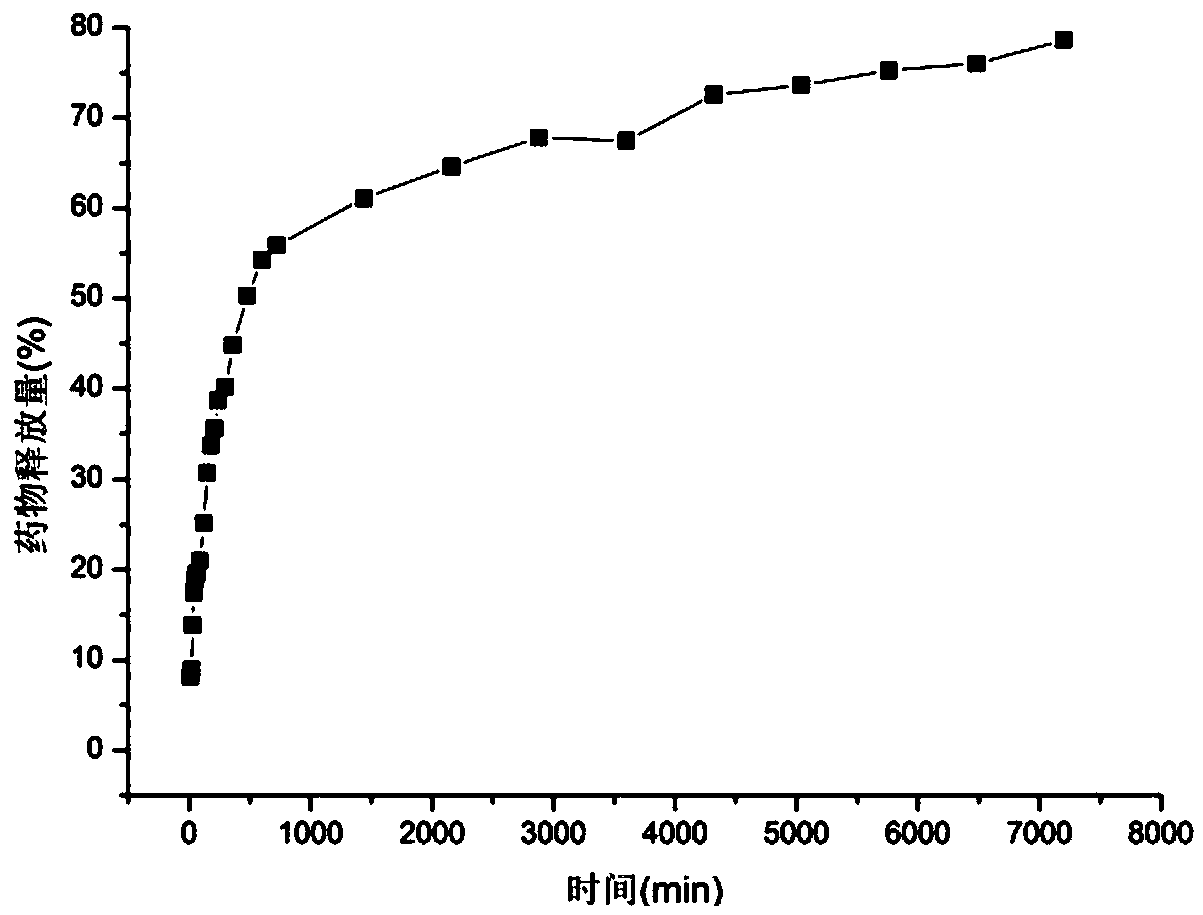

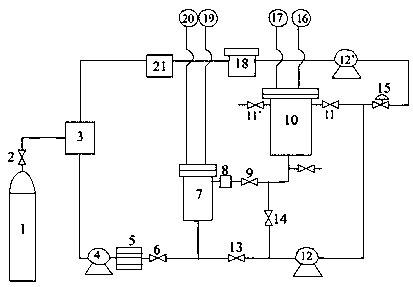

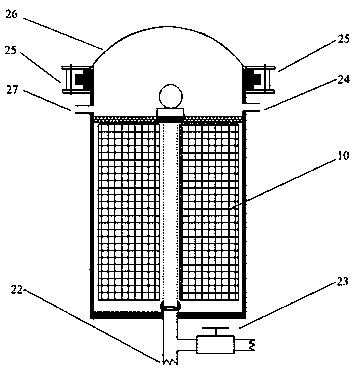

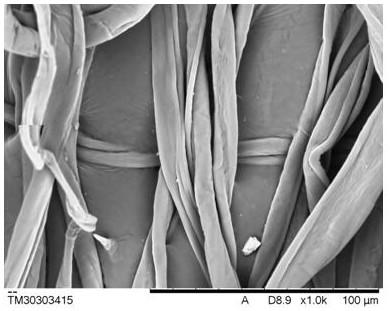

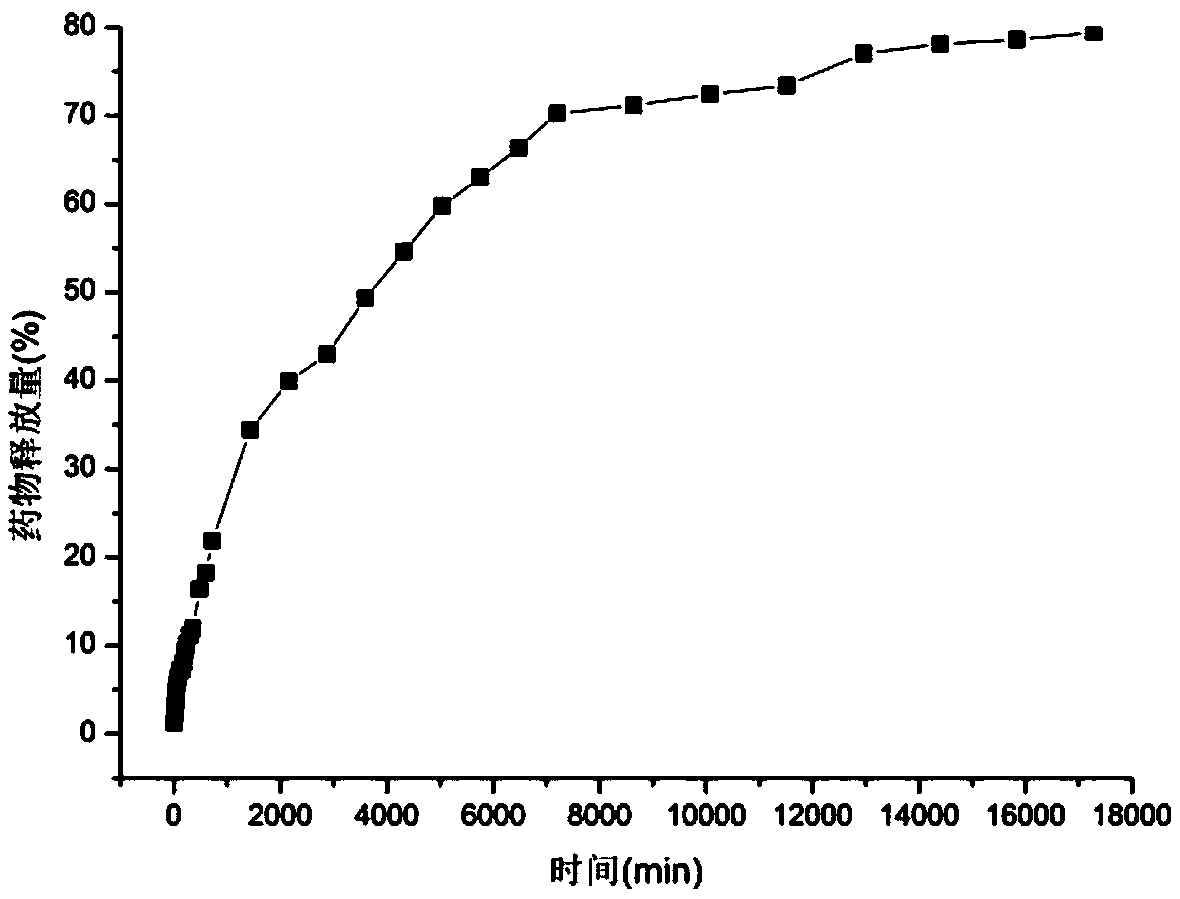

Processing method for providing anti-wrinkle function to cellulose fiber based on supercritical CO2 fluid technology

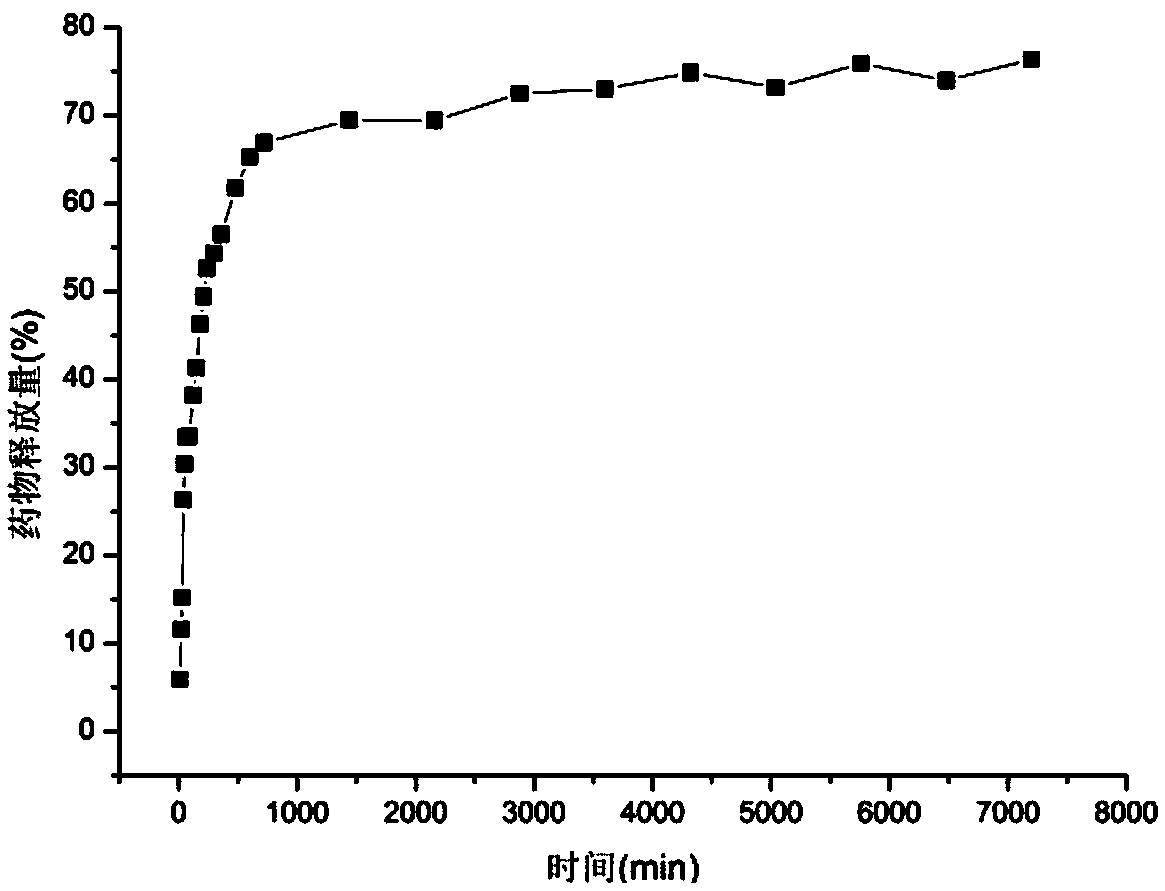

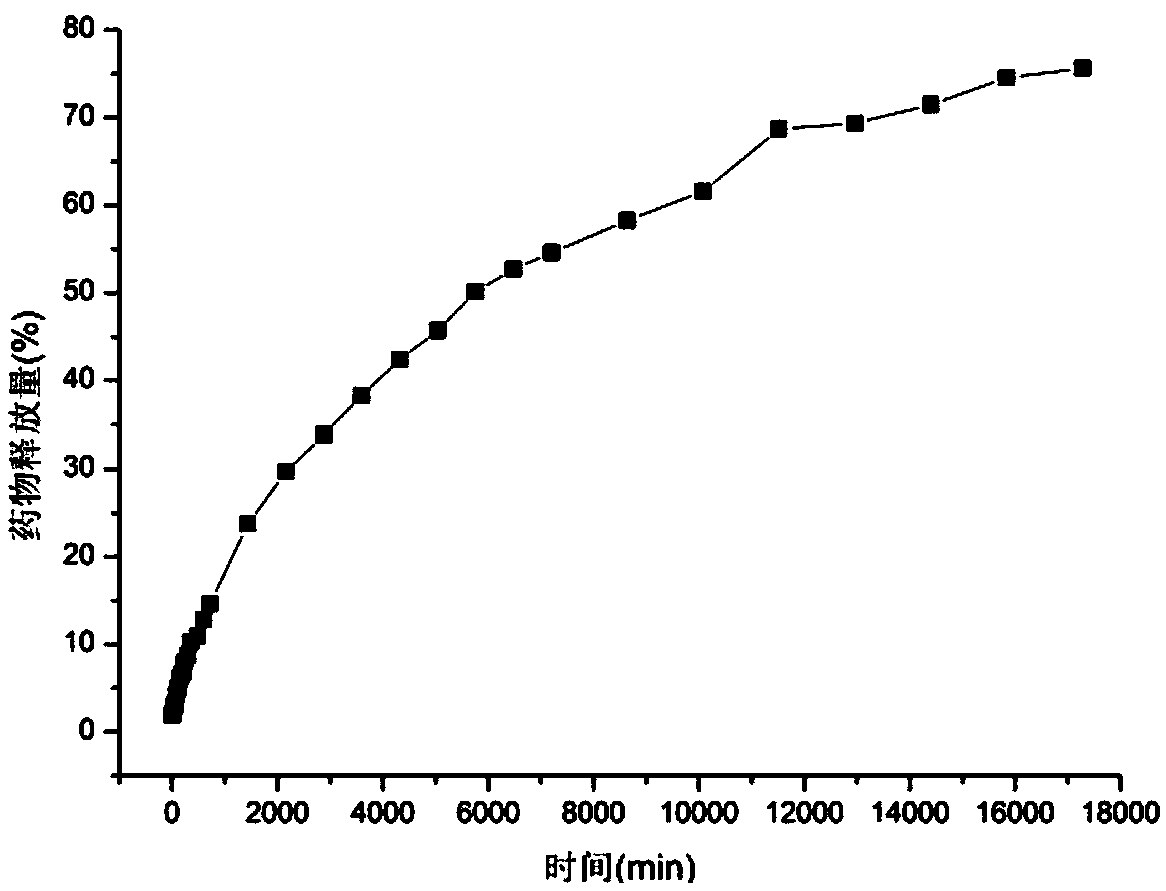

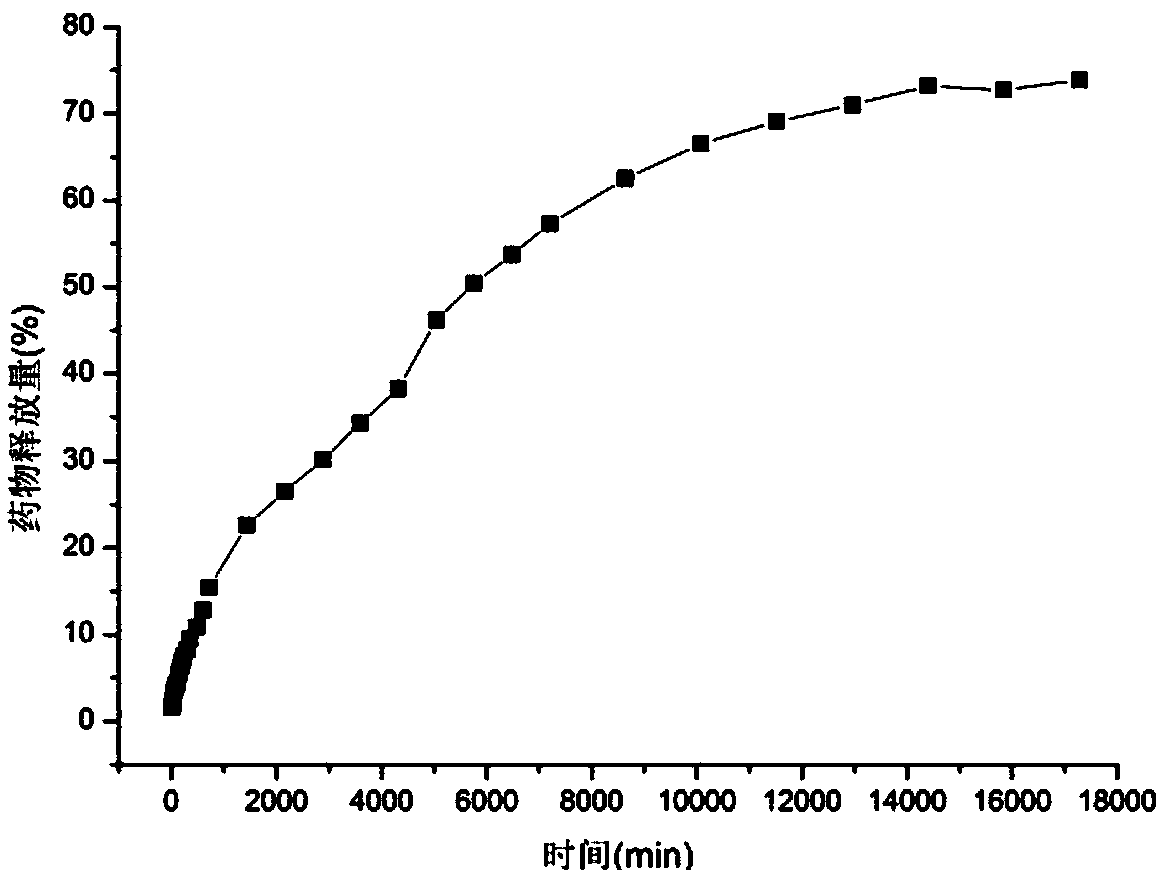

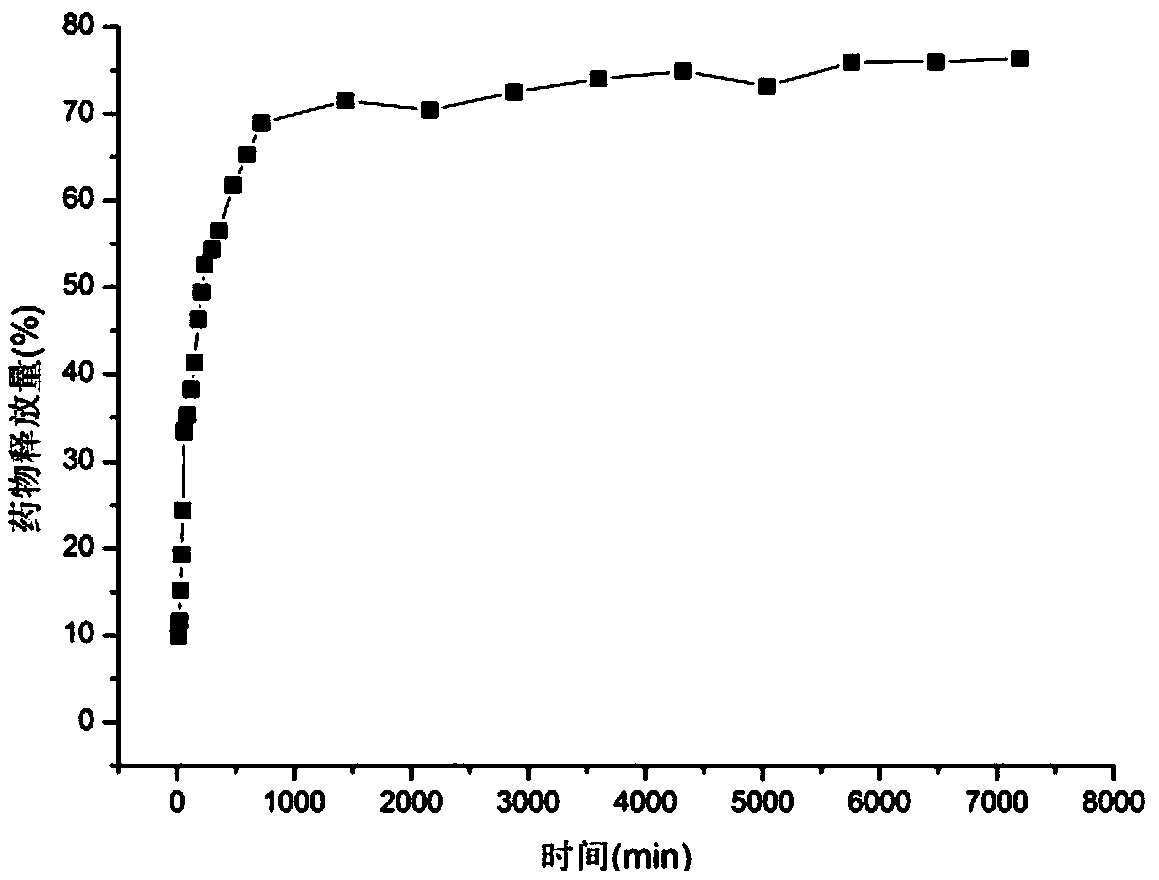

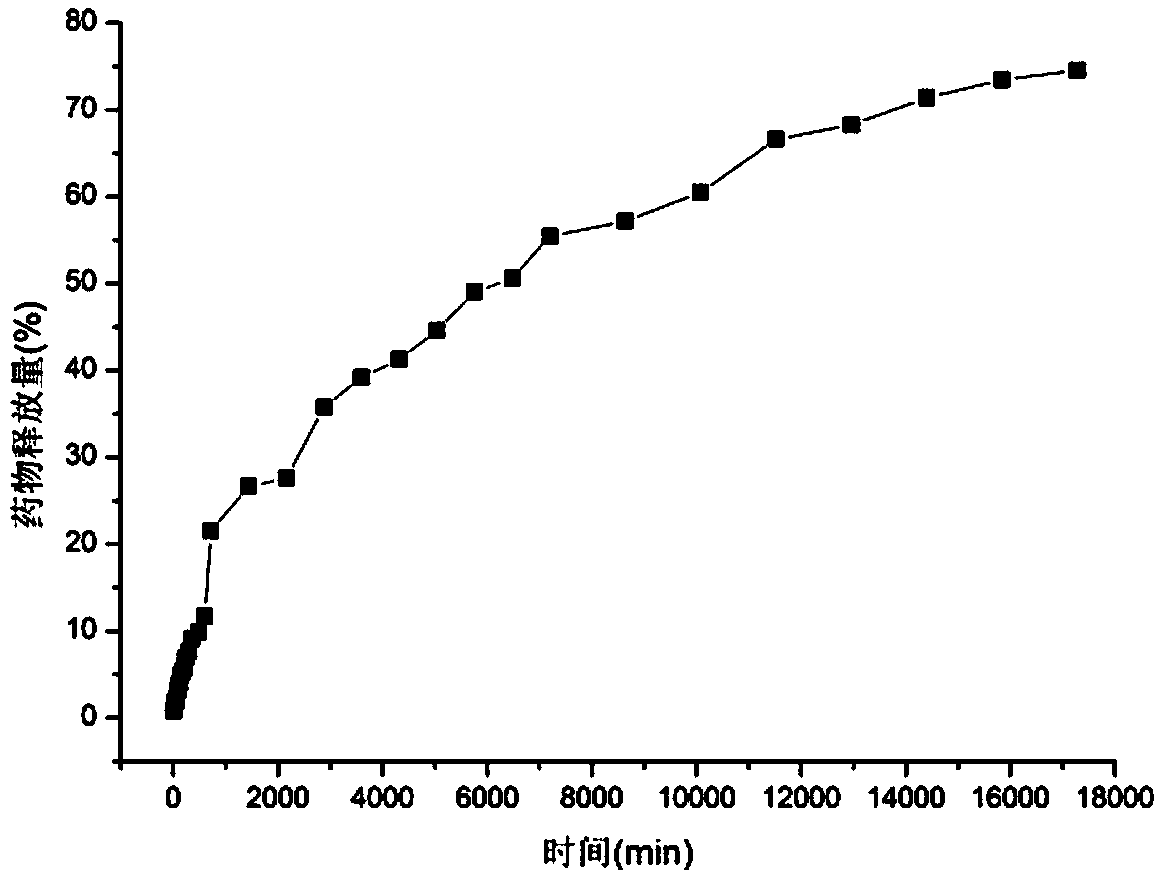

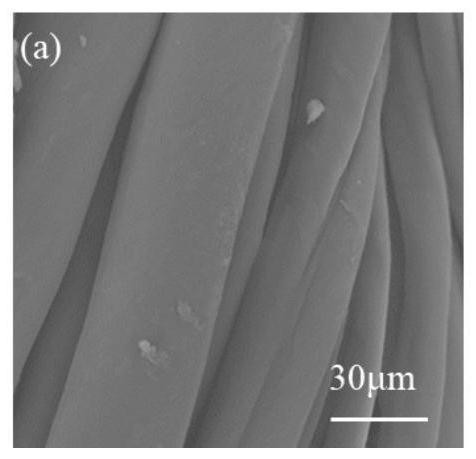

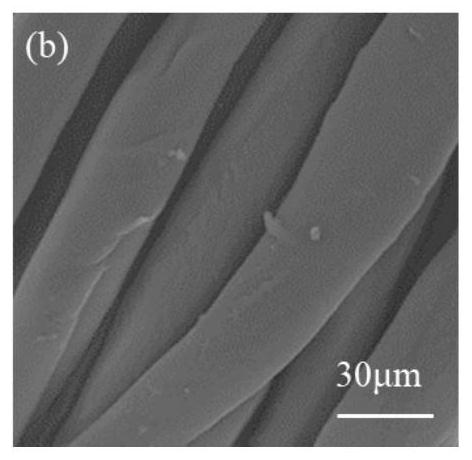

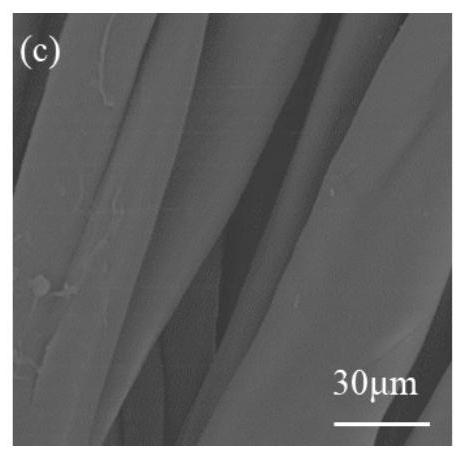

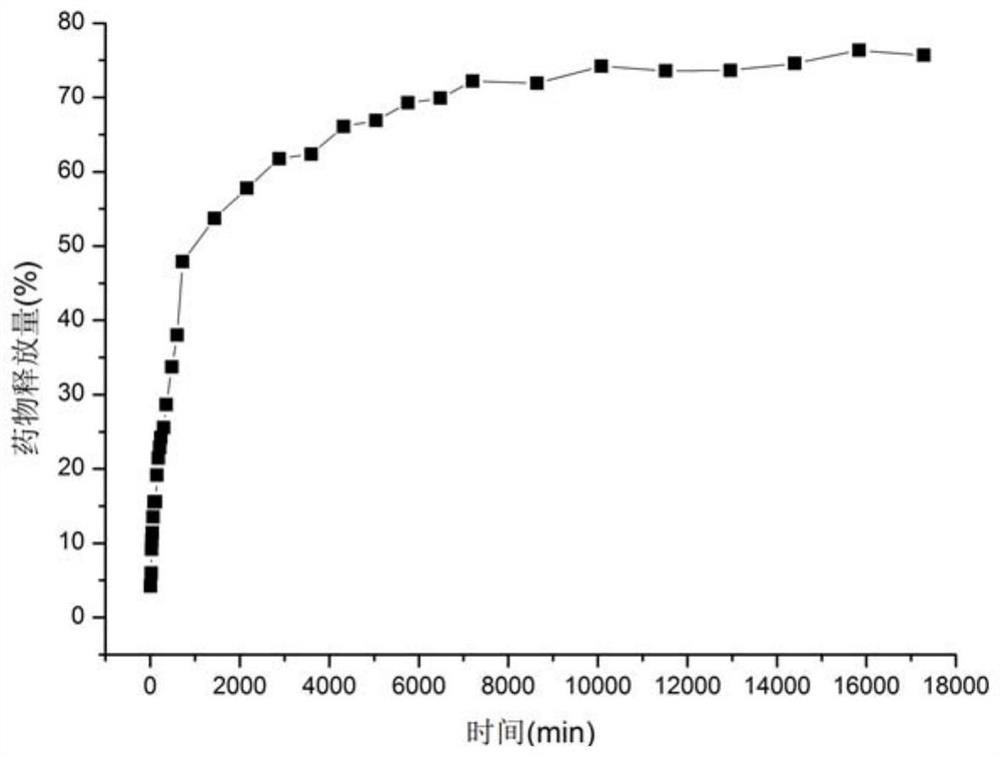

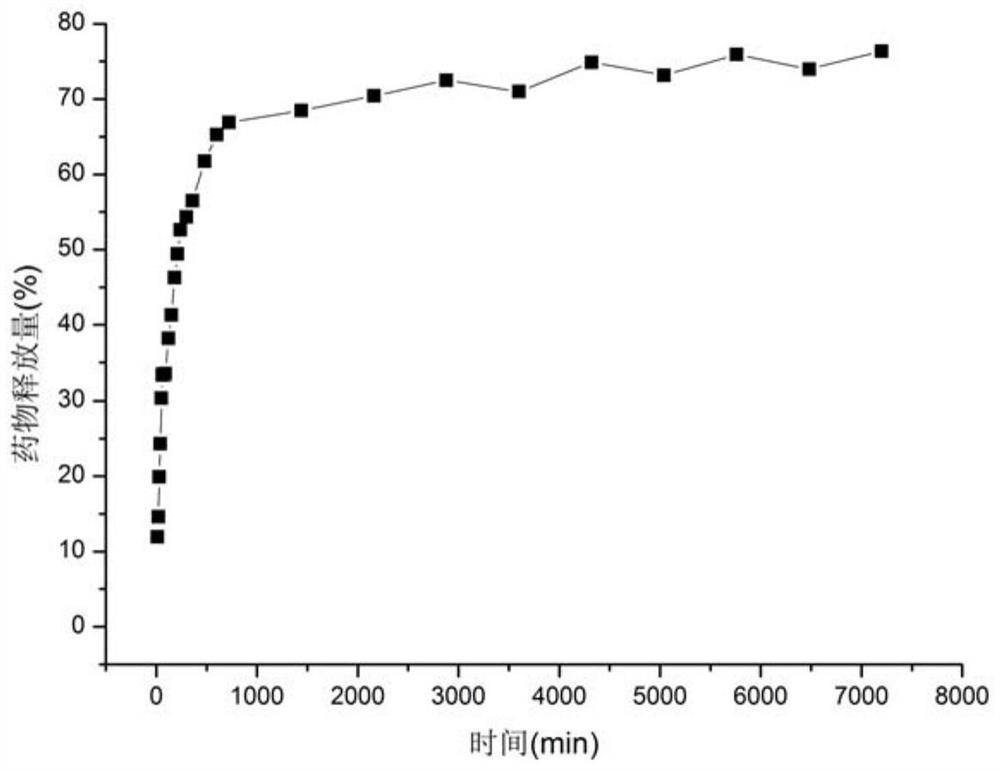

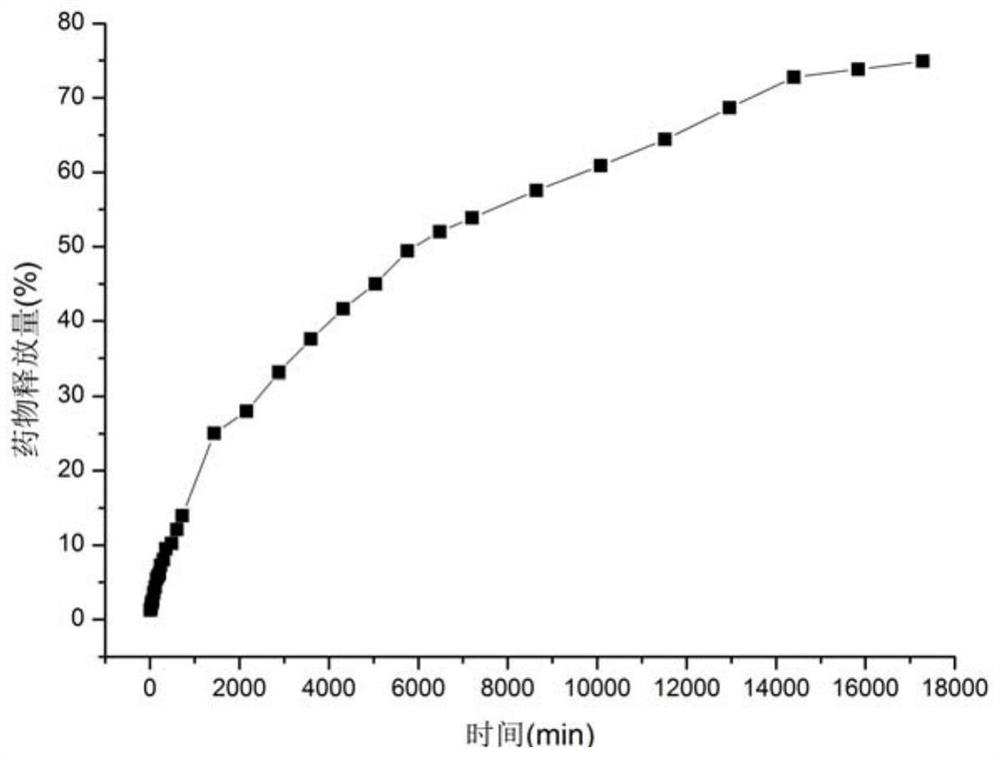

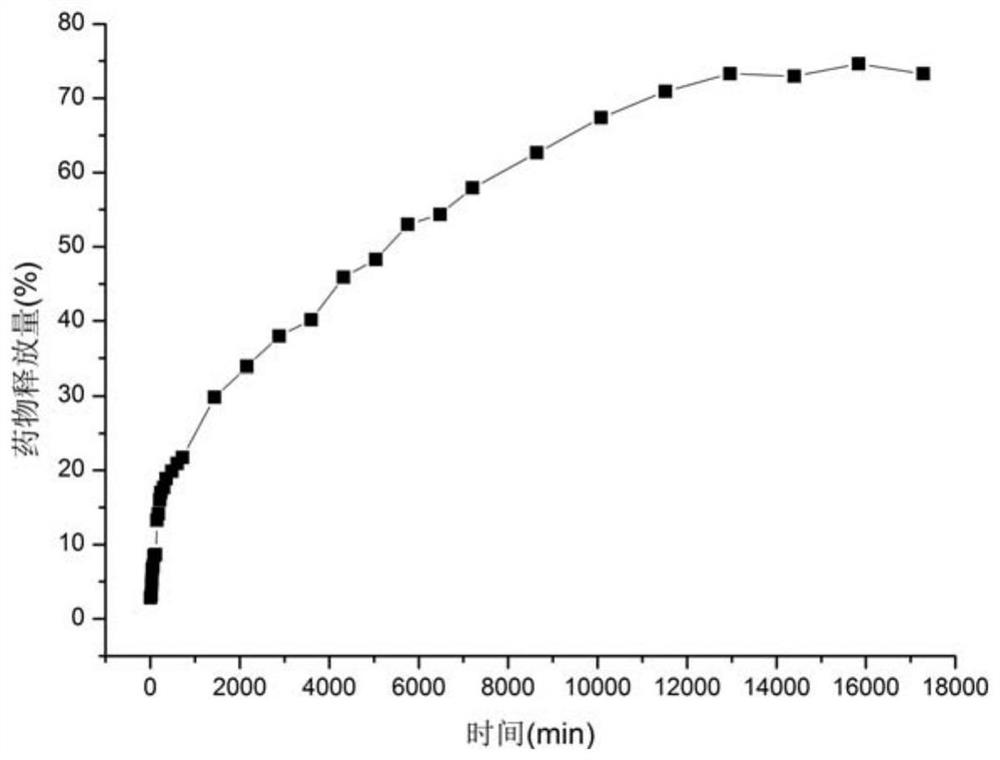

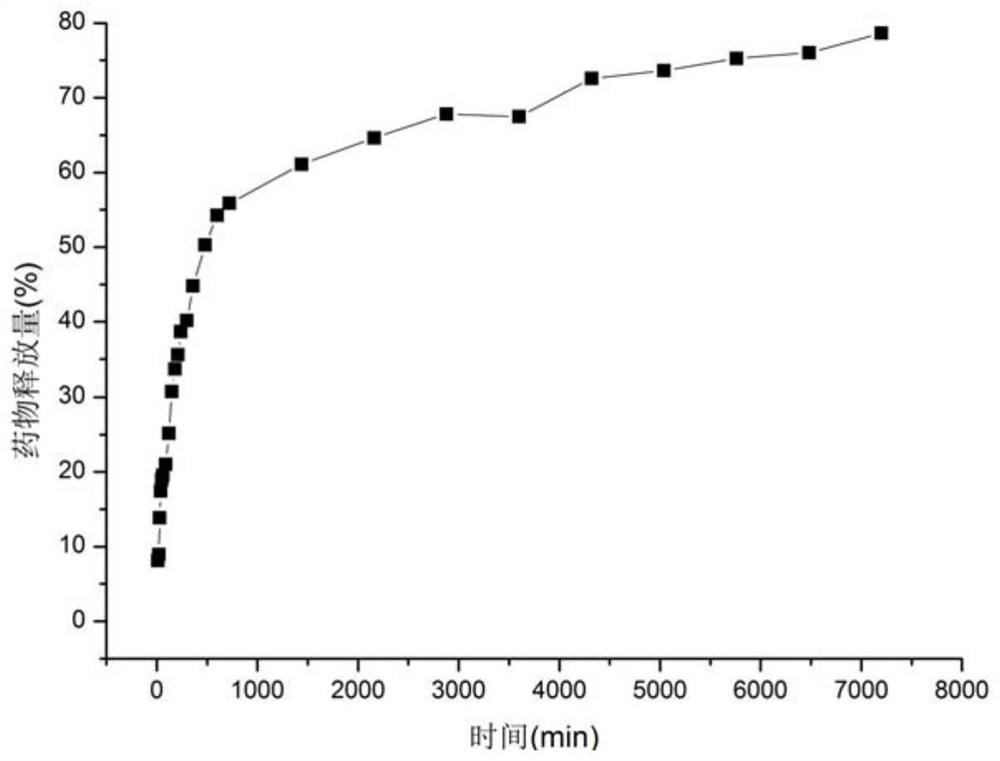

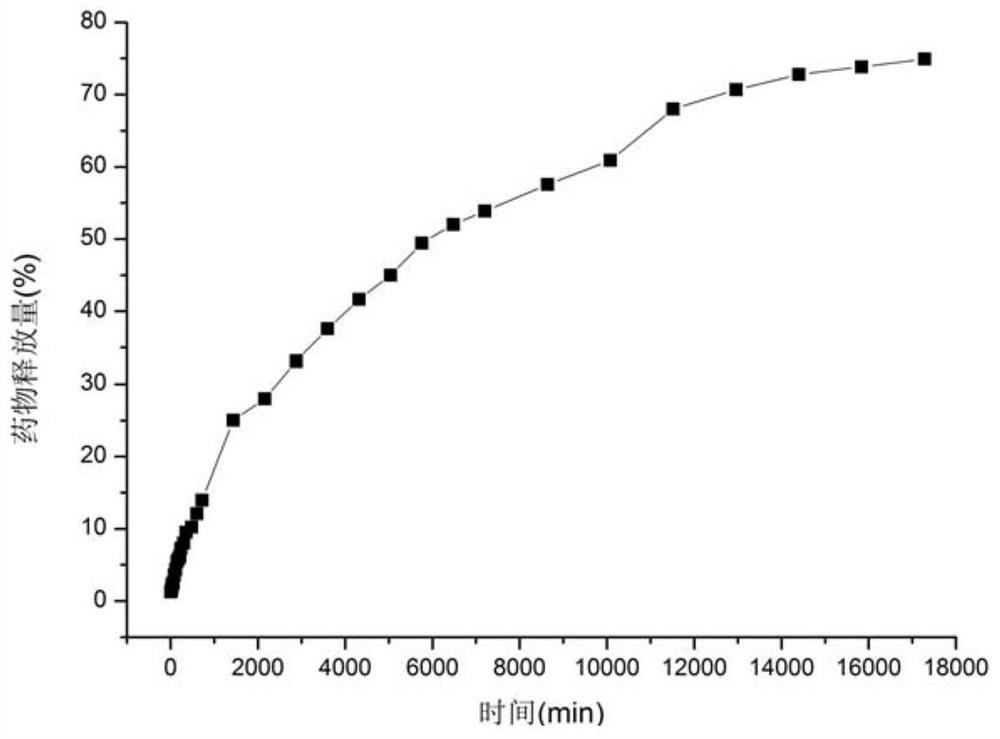

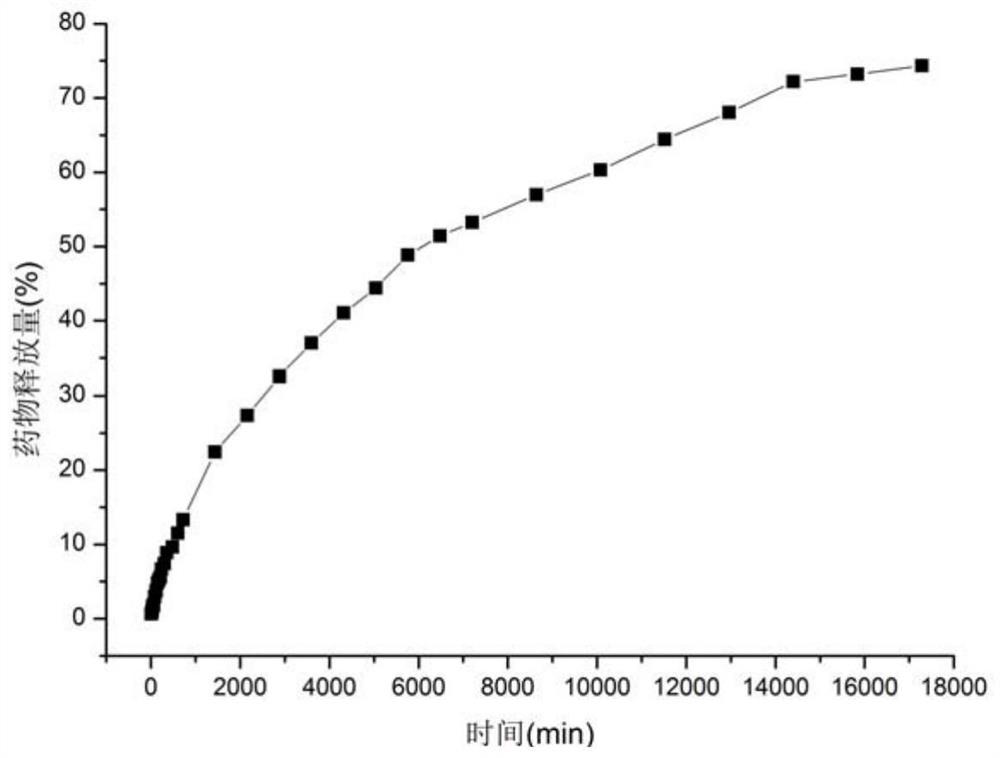

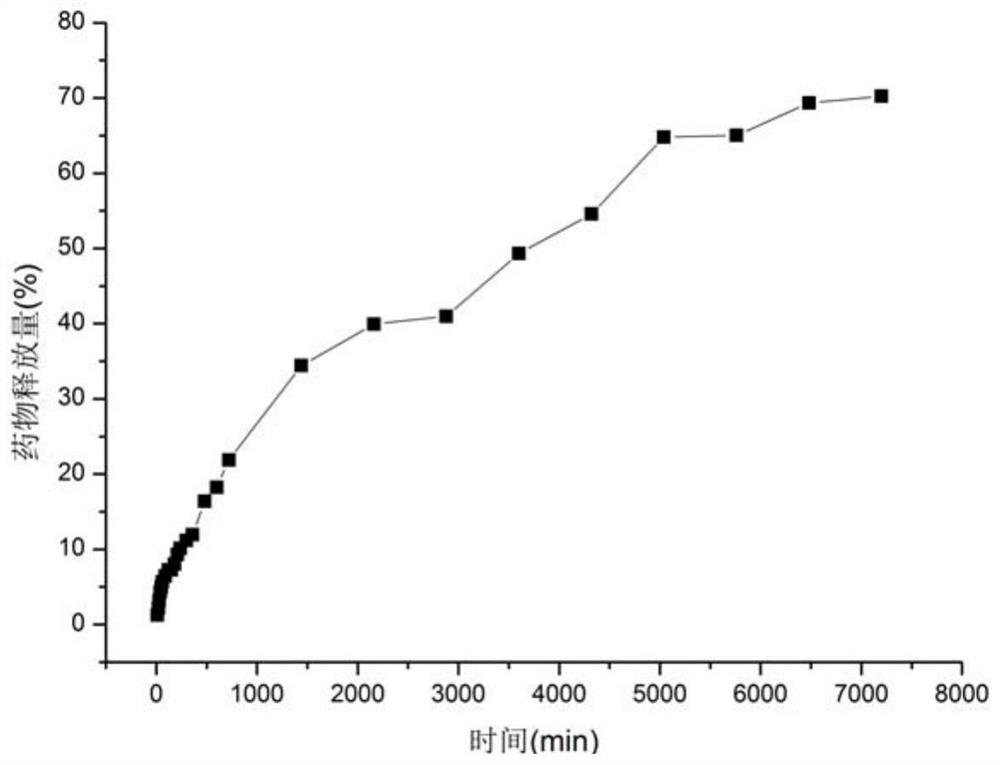

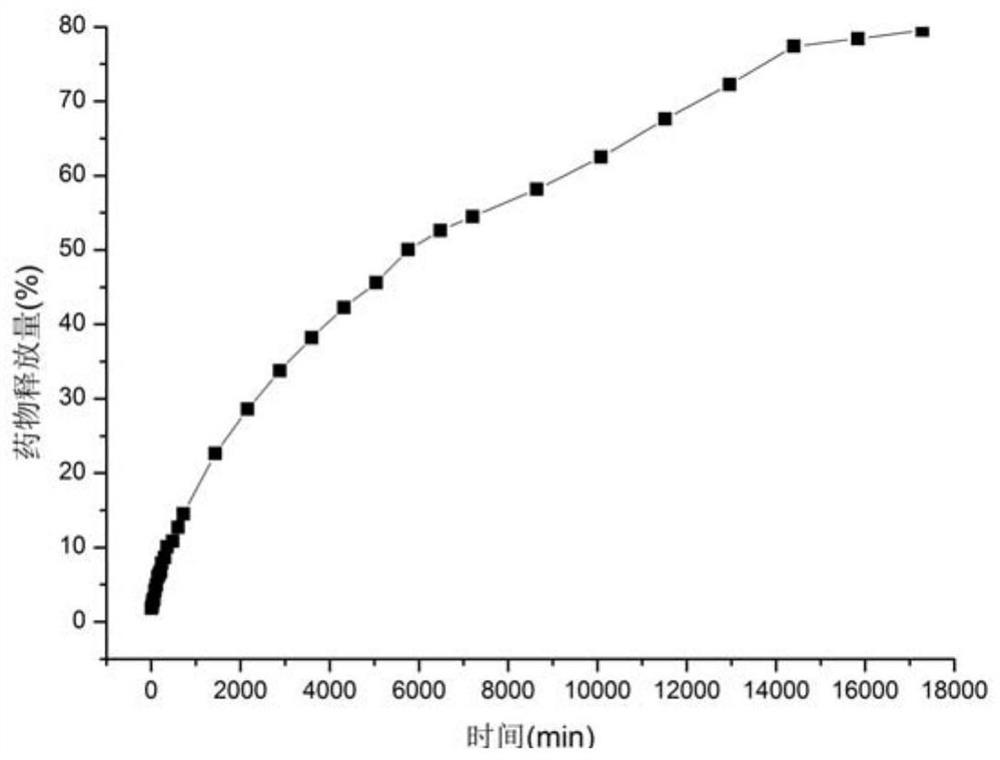

ActiveCN109023960AIncrease the amorphous regionGood slow releaseWrinkle resistant fibresVegetal fibresSolubilityCellulose fiber

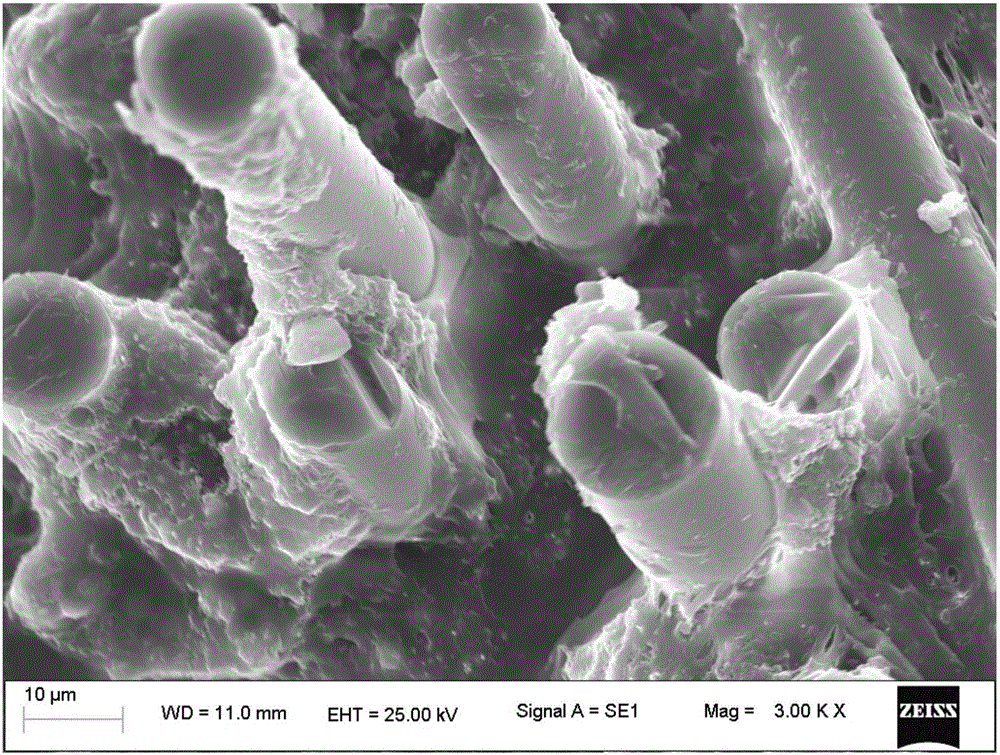

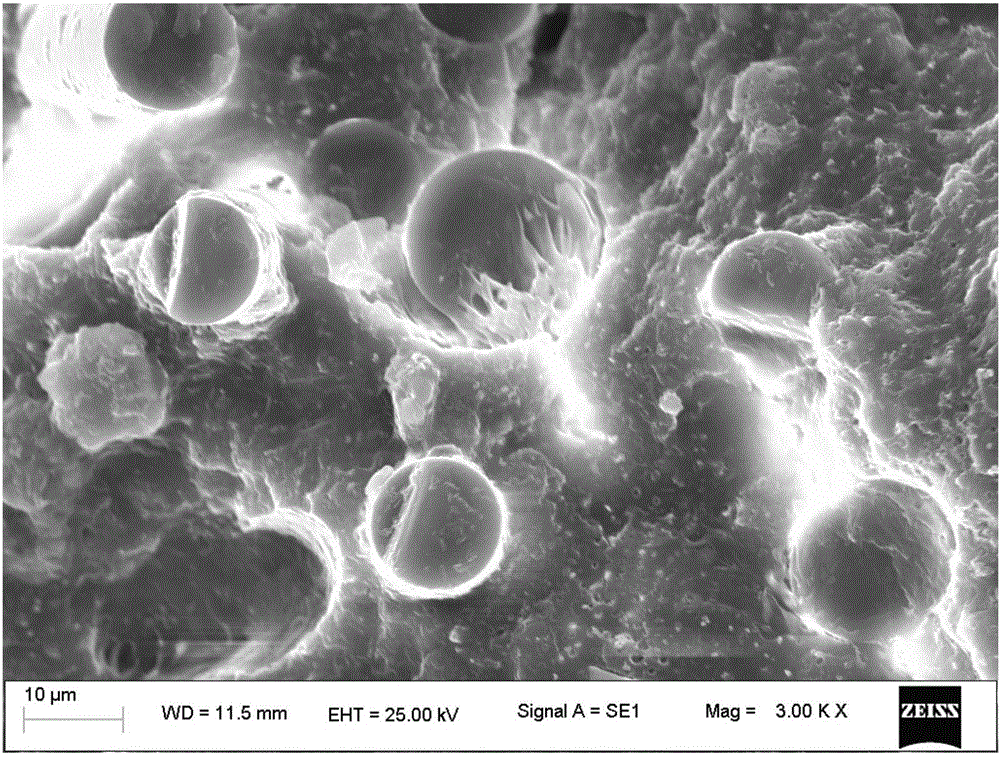

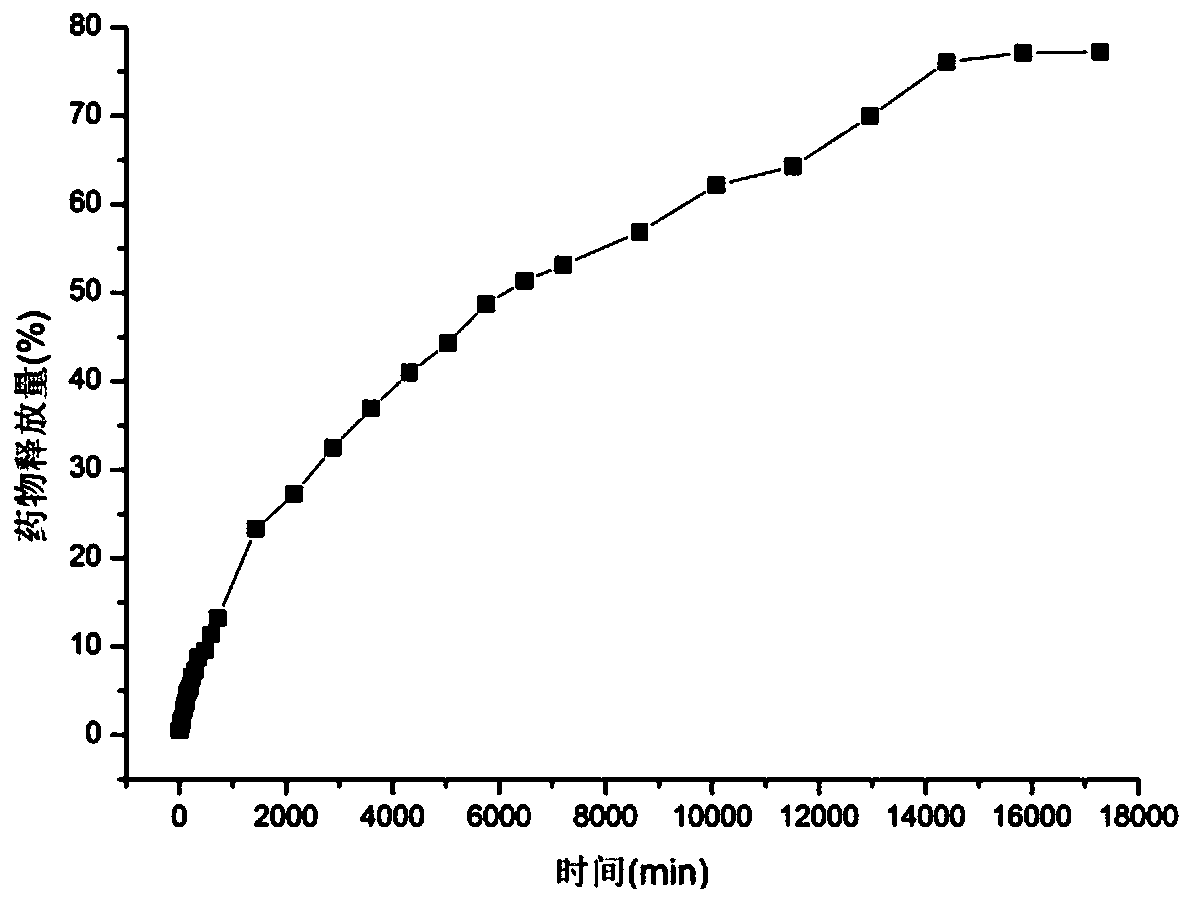

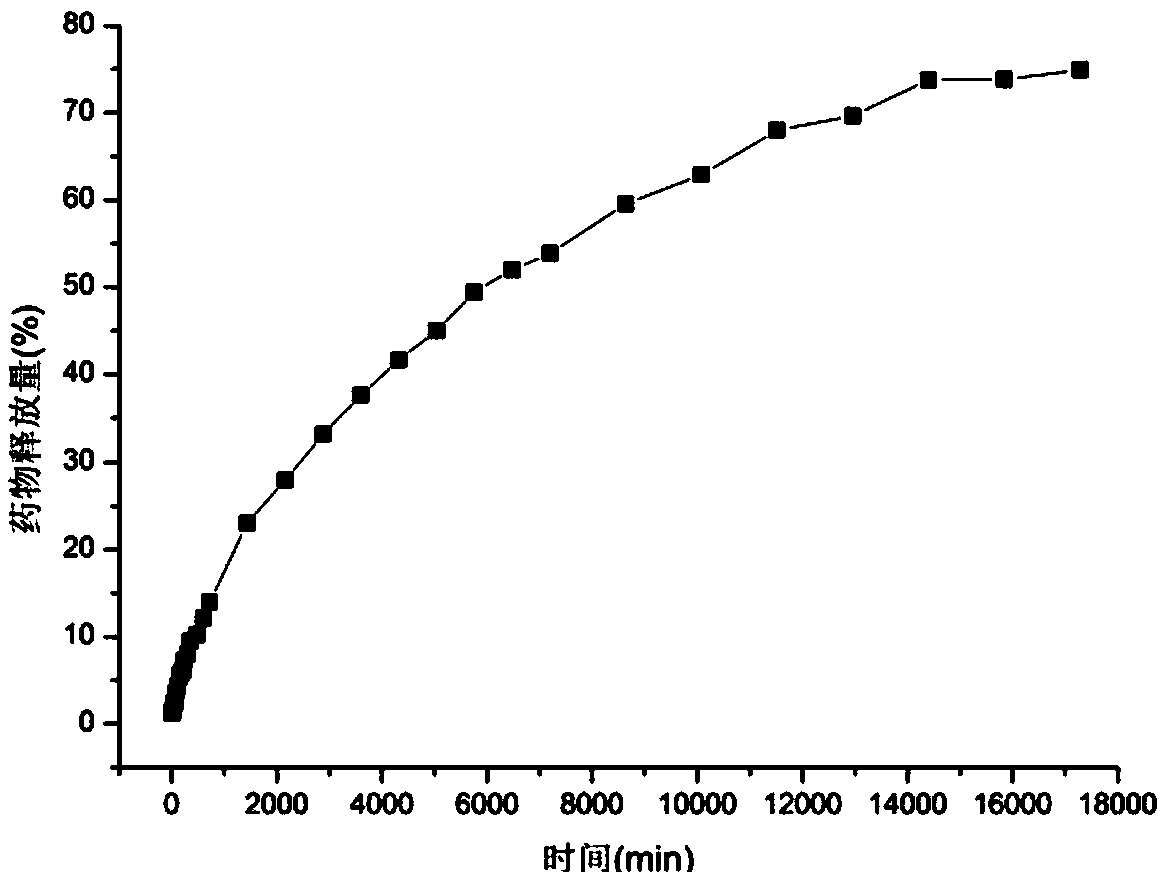

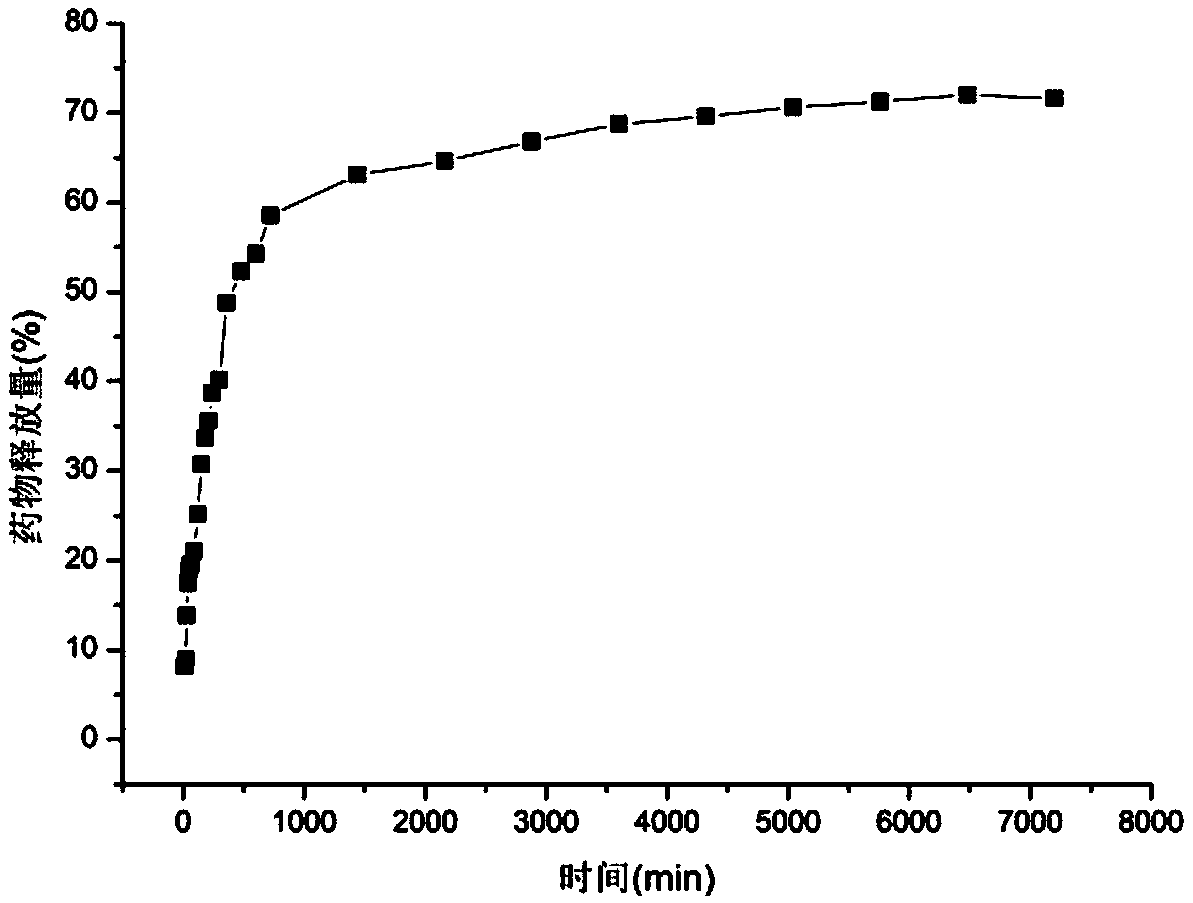

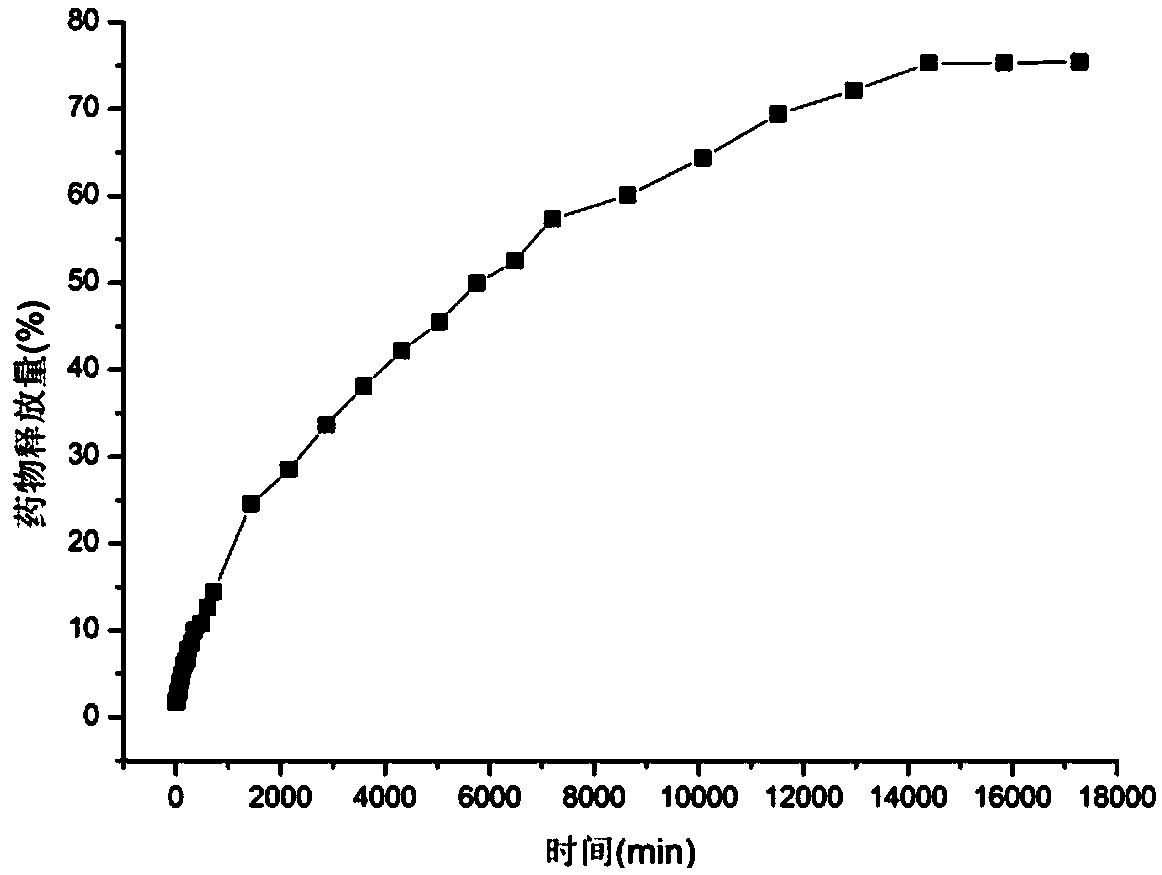

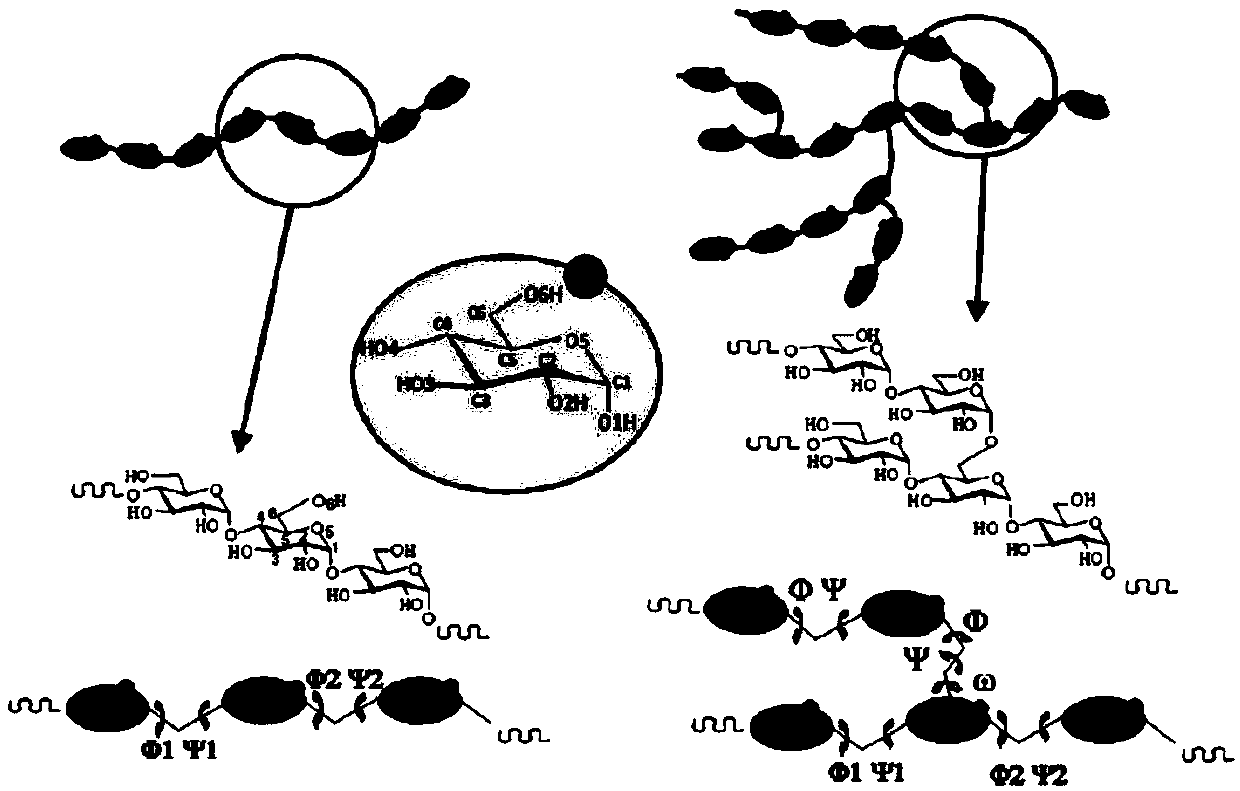

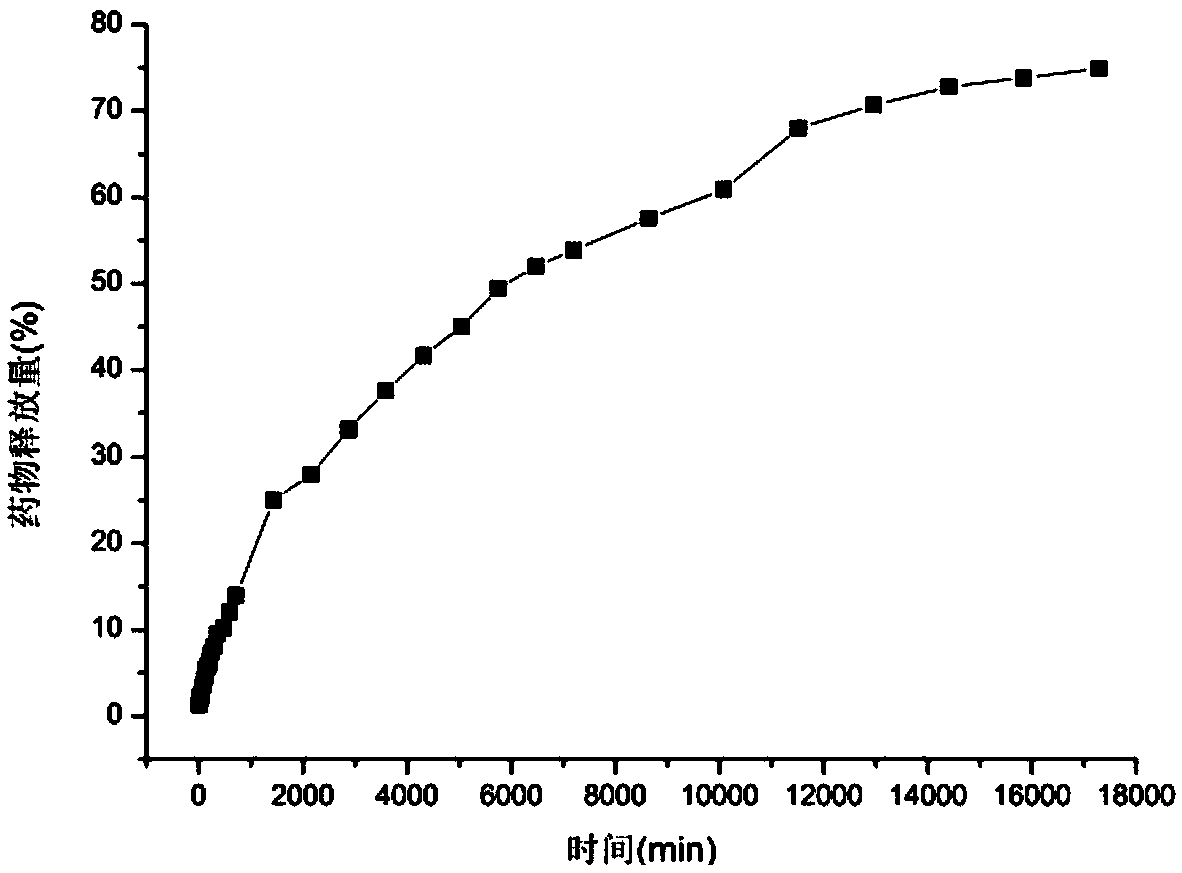

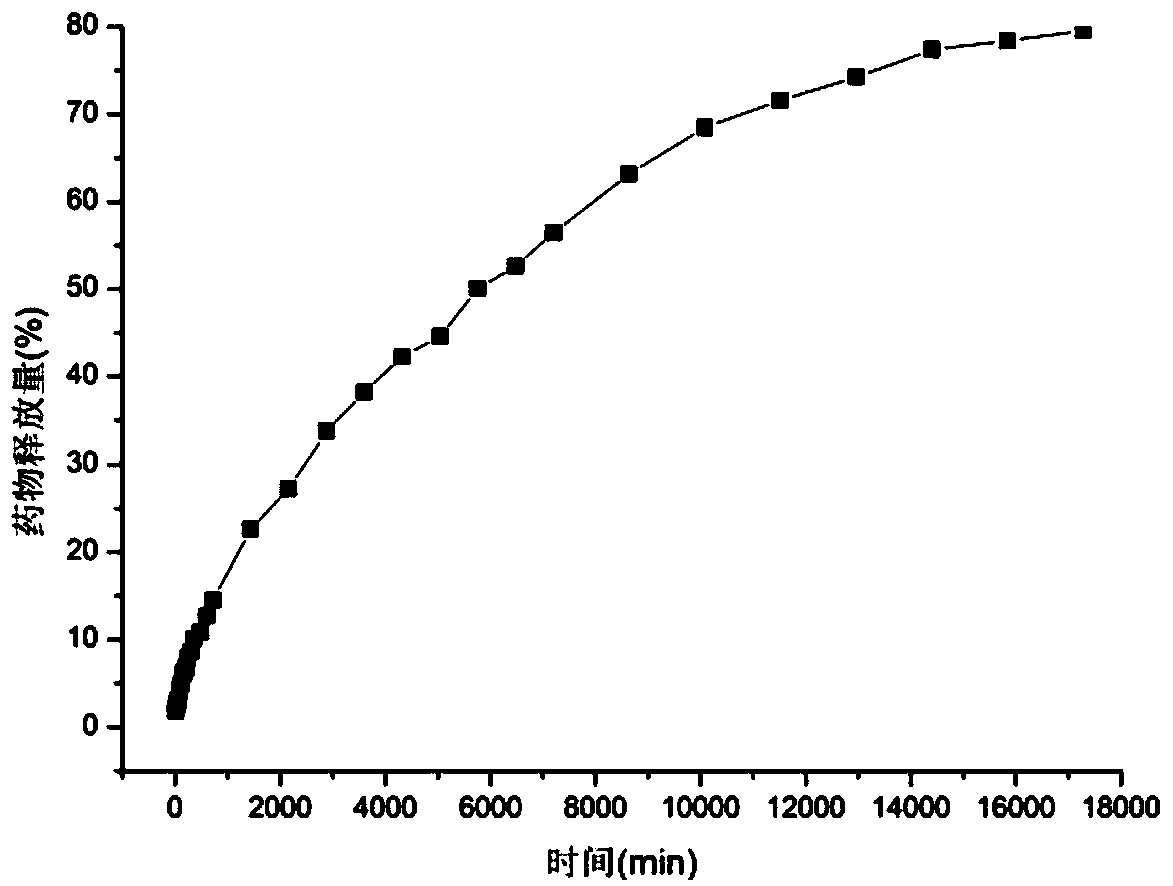

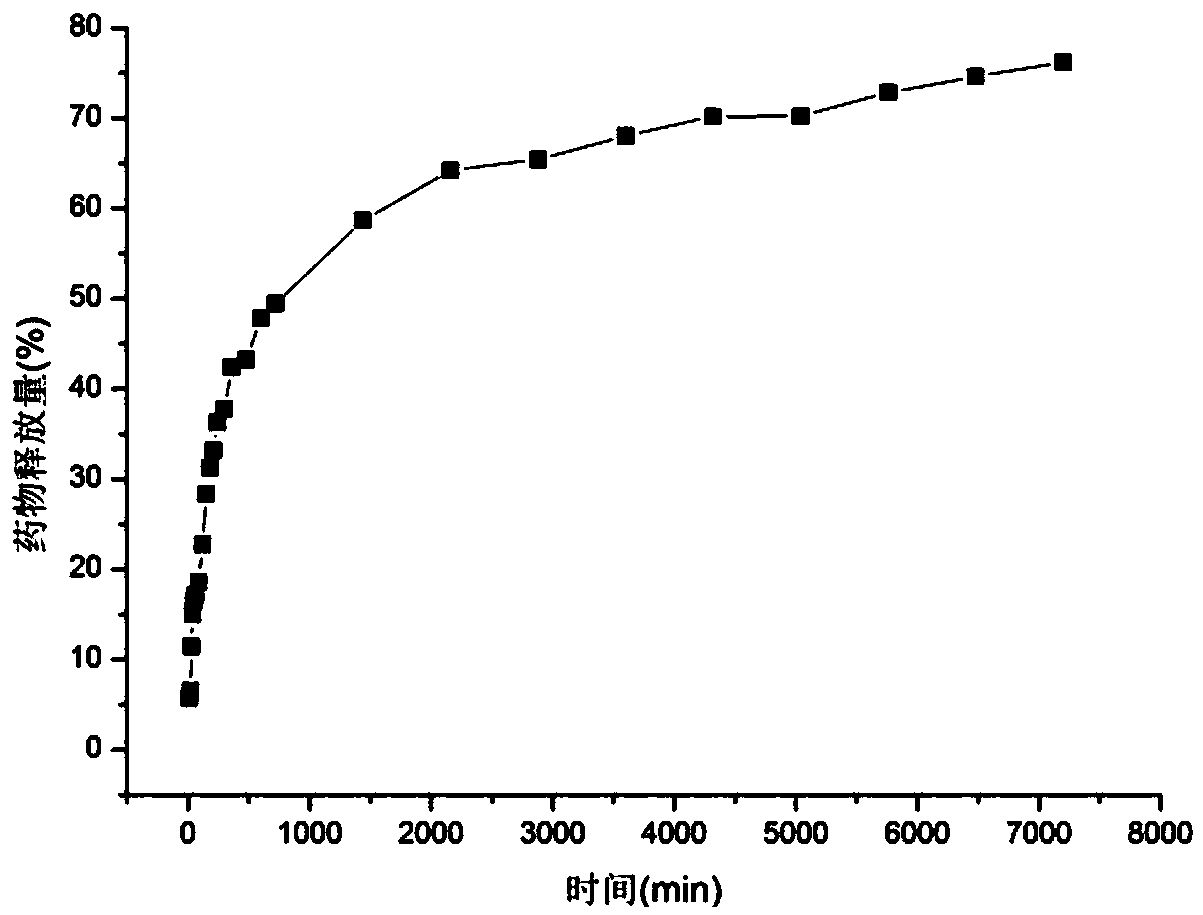

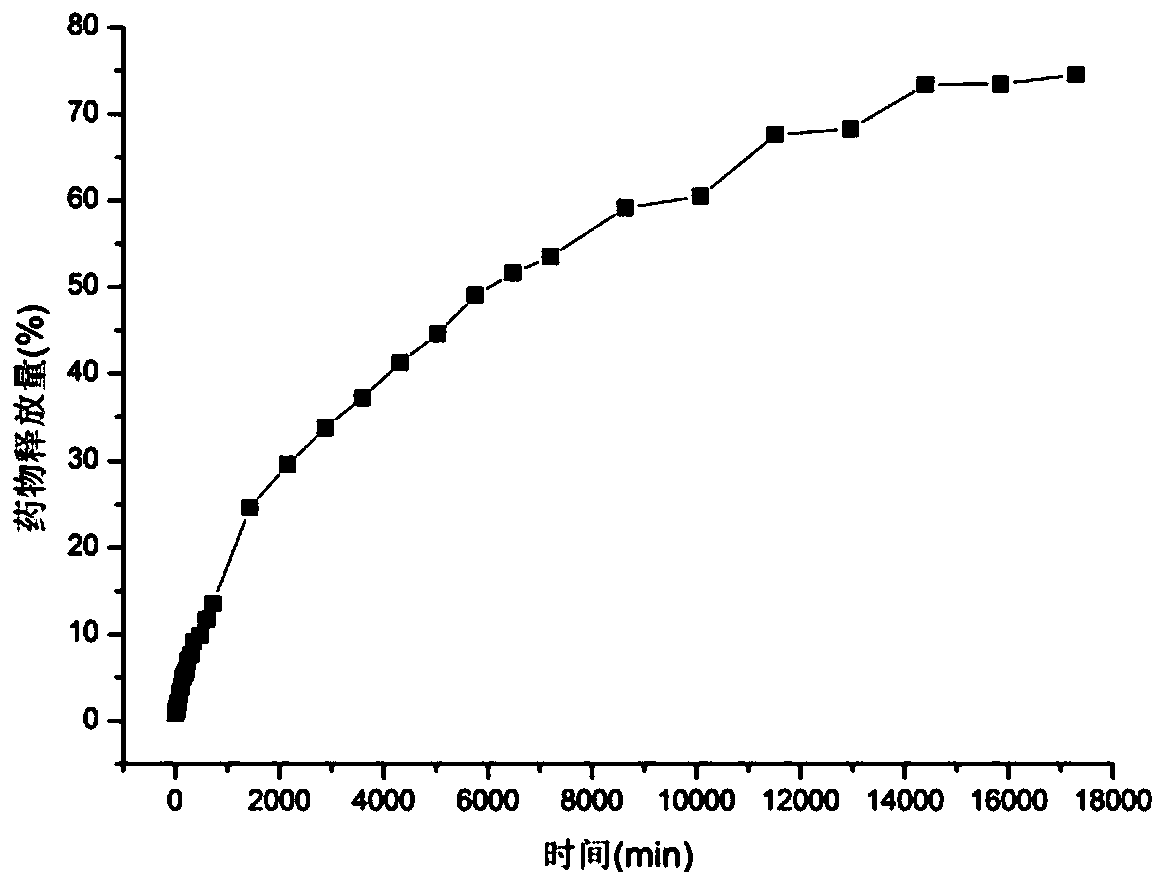

The invention relates to a processing method for providing an anti-wrinkle function to cellulose fiber based on a supercritical CO2 fluid technology. The method comprises the following steps: 1) pre-swelling or pretreating is carried out on the cellulose fibers; 2) auxiliaries are added to increase the solubility of anti-wrinkle drugs in supercritical CO2 fluids, and the hydrophilic anti-wrinkle drugs insoluble in the supercritical CO2 can be directly dissolved in the supercritical CO2 by employing a supercritical microemulsion / anti-micelles method; 3) the anti-wrinkle drugs are added to a medicine tank of high-pressure equipment, the air is removed, the CO2 is introduced, and the pressure in a container is raised to 8-30 MPa at 32-120 DEG C to obtain the supercritical CO2 fluid, so that the cellulose fiber is immersed in the supercritical CO2; and 4) the anti-wrinkle drug enters the pre-swollen cellulose fiber by dissolving in the supercritical CO2 fluid, and continuous relative movement between the drug-loaded supercritical CO2 and the cellulose fiber is carried out, after the pressure is released, the anti-wrinkle drug stays in an amorphous region of the cellulose fiber, and thedrug-loaded cellulose fiber for slow release can be formed.

Owner:SUZHOU UNIV +2

Method for preparing sodium carboxymethylcellulose with degree of substitution from bagasse

The invention discloses a method for preparing sodium carboxymethylcellulose with the degree of substitution from bagasse. The method comprises the following steps of: performing ball-milling pretreatment on bagasse fibers, and etherifying bagasse cellulose and purifying. In the method, the bagasse fibers are subjected to the ball-milling pretreatment, so a lignin protective layer is broken, a crystalline structure of the cellulose is changed, an amorphous area of the bagasse cellulose is increased, and the reaction activity of the bagasse cellulose is improved; and by a subsequent series of methods and the optimization of control parameters, the degree of substitution of the prepared sodium carboxymethylcellulose is up to 1.5, the yield is 50 percent, the production cost is low, and a process is simple and environment-friendly.

Owner:YULIN NORMAL UNIVERSITY

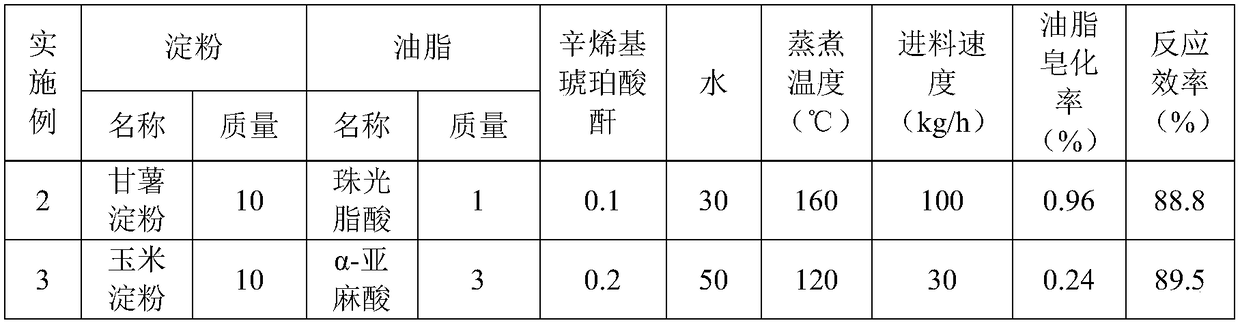

Method for preparing starch stearate by using cassava starch

The invention discloses a method for preparing starch stearate by using cassava starch. The method comprises the steps of: a, grinding the cassava starch with a moisture content of 10-20% and a ball-milling medium at 40-60 DEG C to prepare activated cassava starch; b, weighing stearic acid accounting for 0.5-5% by mass of the activated starch, dissolving the stearic acid in absolute ethyl alcohol until an acid alcohol ratio is 1 g: (20-30) m1, then adding hydrochloric acid accounting for 0.0175-0.175% by mass of the activated starch and mixing uniformly; c, adding the solution obtained in the step b into the activated cassava starch obtained in the step a, mixing uniformly and then adding water until the moisture content in the starch is up to 15-40%, cooling to 20-30 DEG C after interval microwave heating, washing with ethanol, and drying at 30-65 DEG C after suction filtration. The method for preparing the starch stearate by using the cassava starch, disclosed by the invention, can prepare starch stearate with high degree of substitution by using the cassava starch, has low production cost and a simple process, and is environment-friendly.

Owner:YULIN NORMAL UNIVERSITY

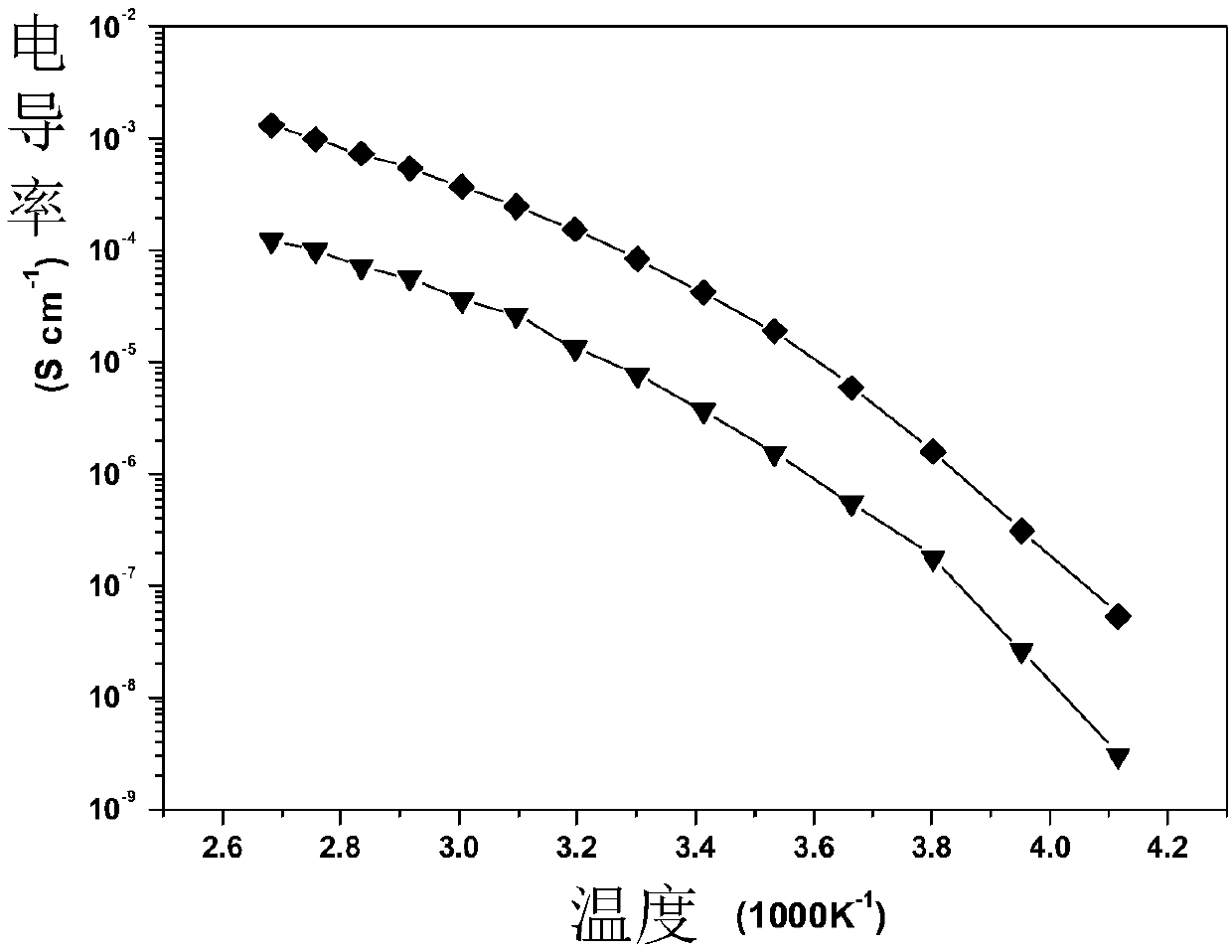

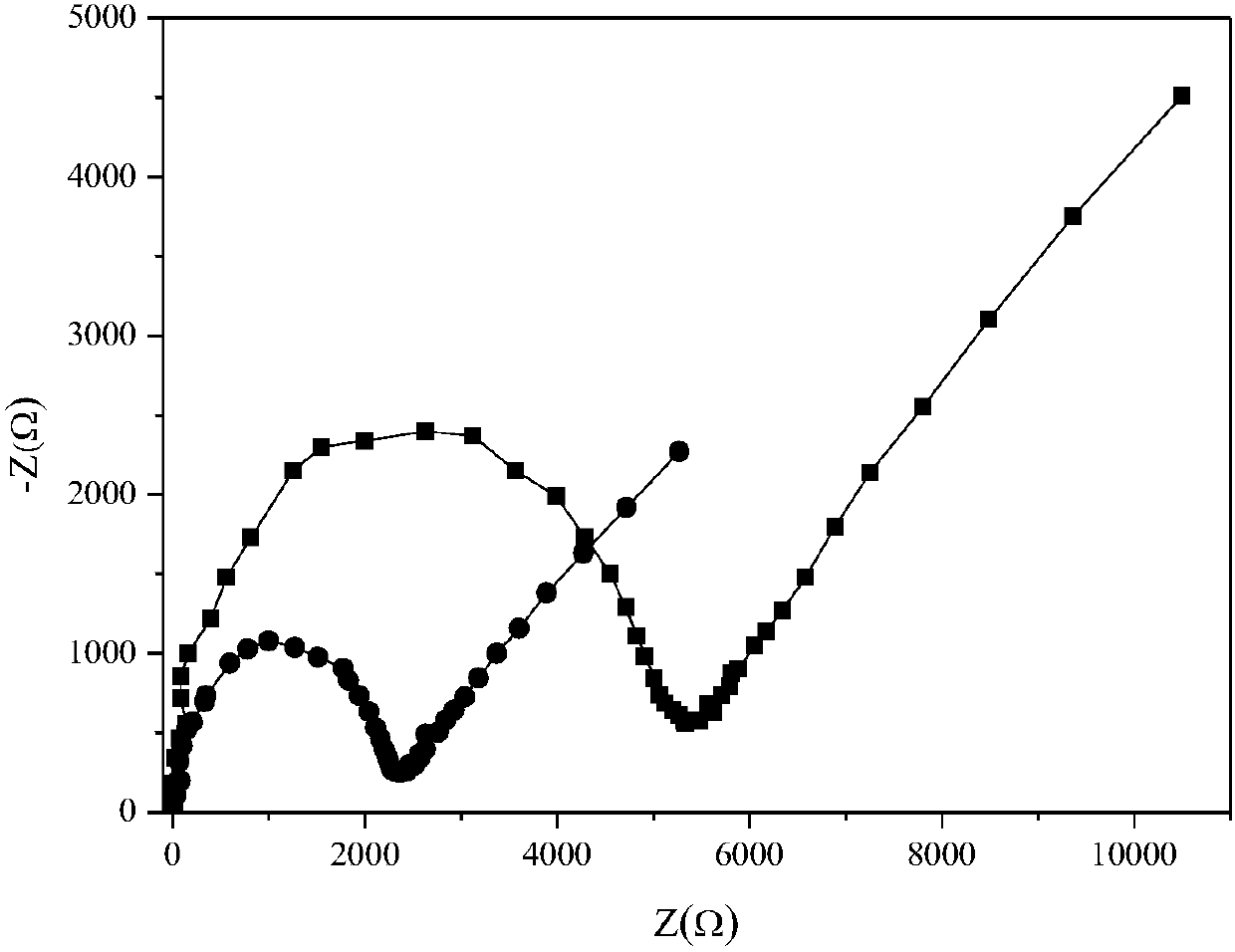

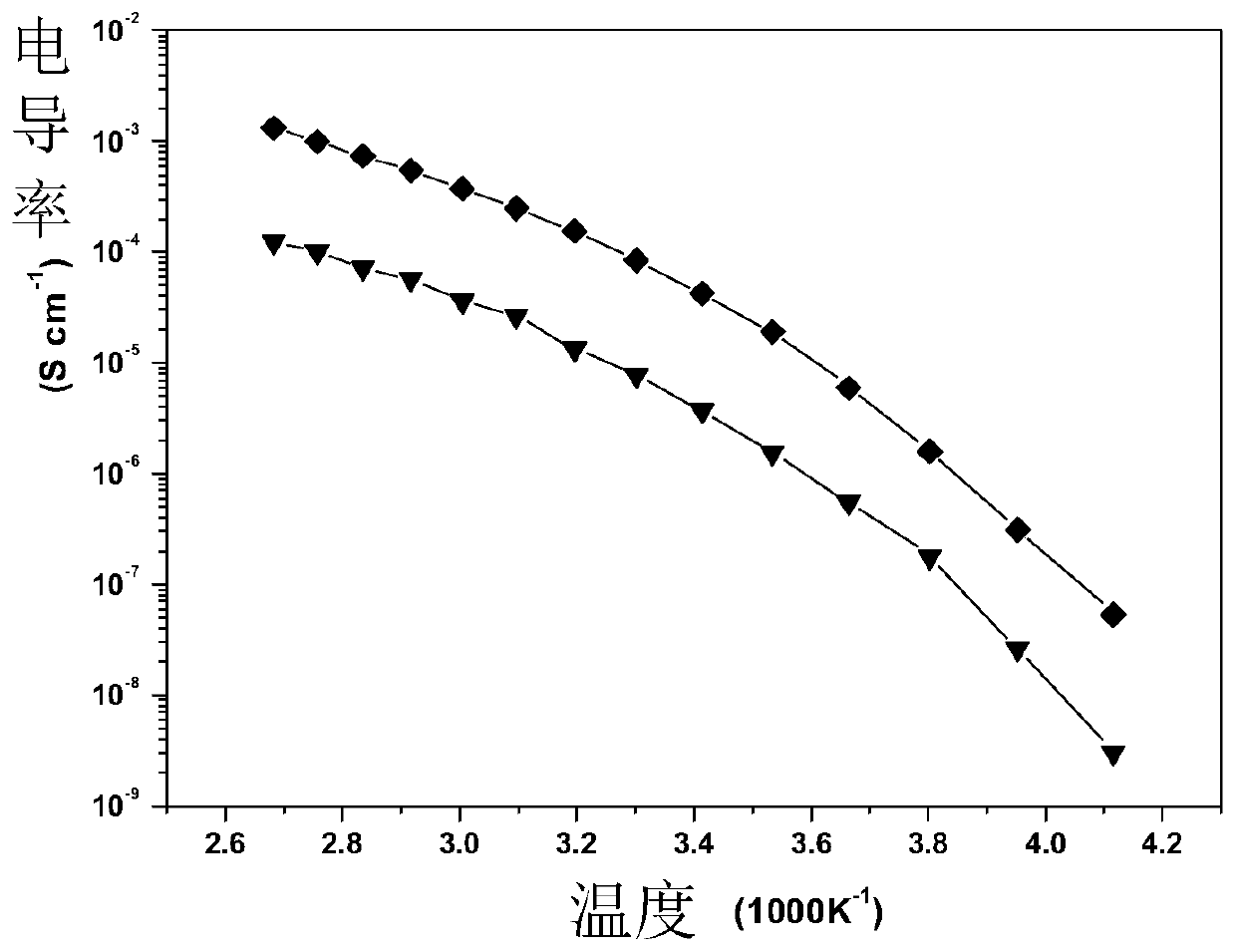

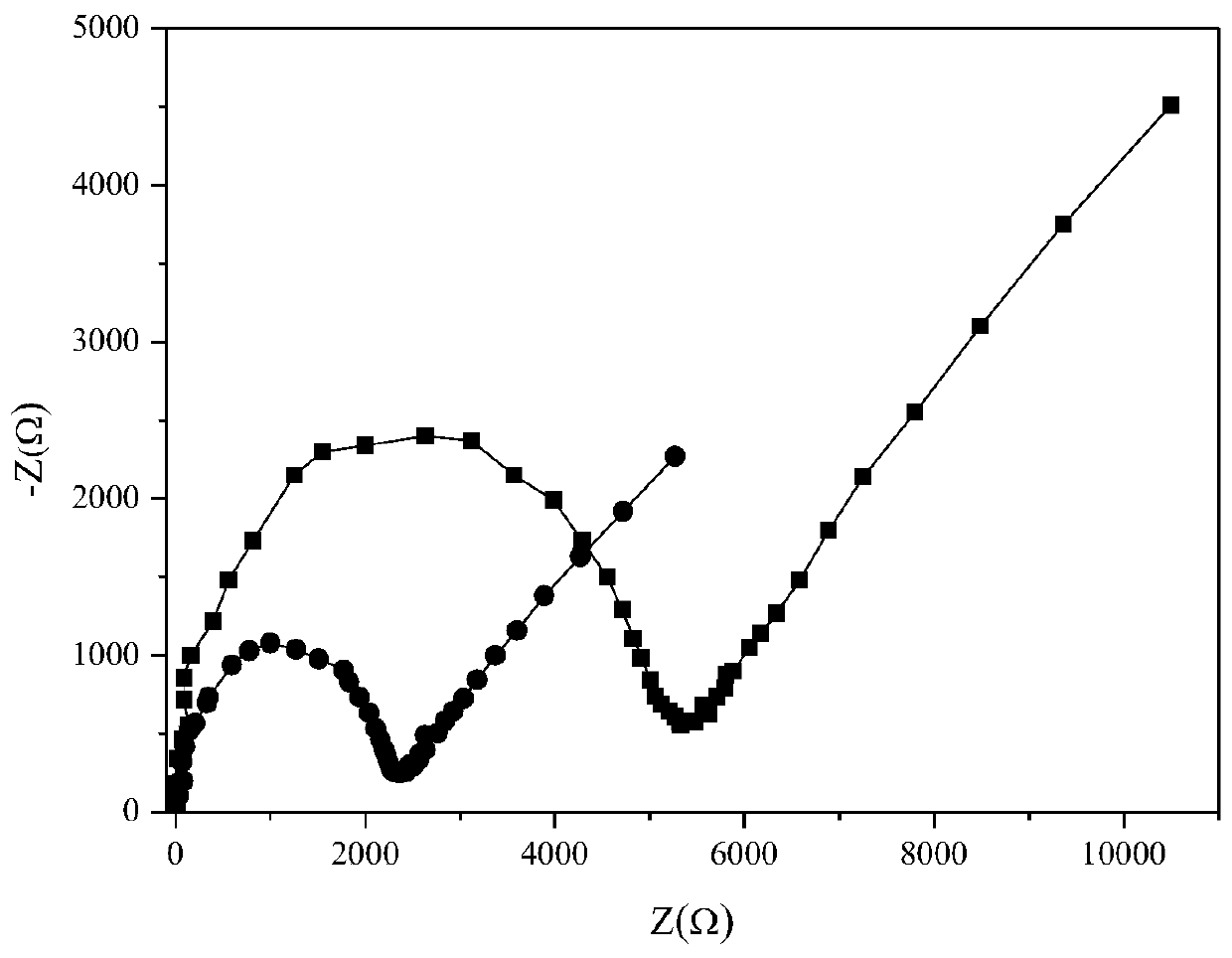

Preparation method of composite polymer electrolyte

ActiveCN107946640AEnhanced low temperature ionic conductivityPrevent crystallizationSecondary cellsPolymer scienceAtom-transfer radical-polymerization

The invention discloses a preparation method of a composite polymer electrolyte. The preparation method of the composite polymer electrolyte comprises the step of obtaining a composite polymer electrolyte through an ion conductive agent; and the preparation method of the ion conductive agent comprises the following steps: in an inert gas atmosphere, dissolving cuprous bromide powder and pentamethyl diethylenetriamine into a first organic solvent to prepare a catalyst solution; adding a monomer A such as N,N-Dimethylaminoethyl Methacrylate, a monomer B such as di(ethylene glycol) methyl ether methacrylate and a first initiator into the catalyst solution respectively, carrying out an atom transfer radical polymerization reaction at the temperature of 75 to 85 DEG C, and reacting for 10 to 60min to obtain a reaction product; adding excess cyclohexane into the reaction product to obtain a flocculent precipitate, and purifying the flocculent precipitate to obtain the ion conductive agent.According to the ion conductive agent, the amorphous region of the composite polymer electrolyte is added, the crystallization of the polymer matrix can be effectively inhibited, the glass transitiontemperature is reduced, and then the low-temperature ionic conductivity of the composite polymer electrolyte is strengthened.

Owner:JIANGHAN UNIVERSITY

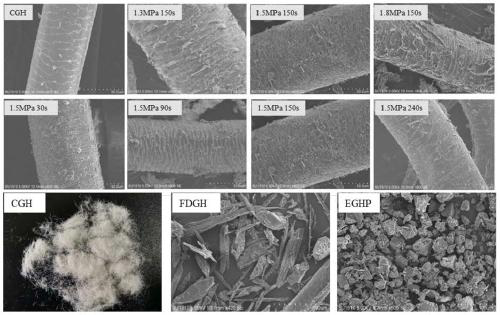

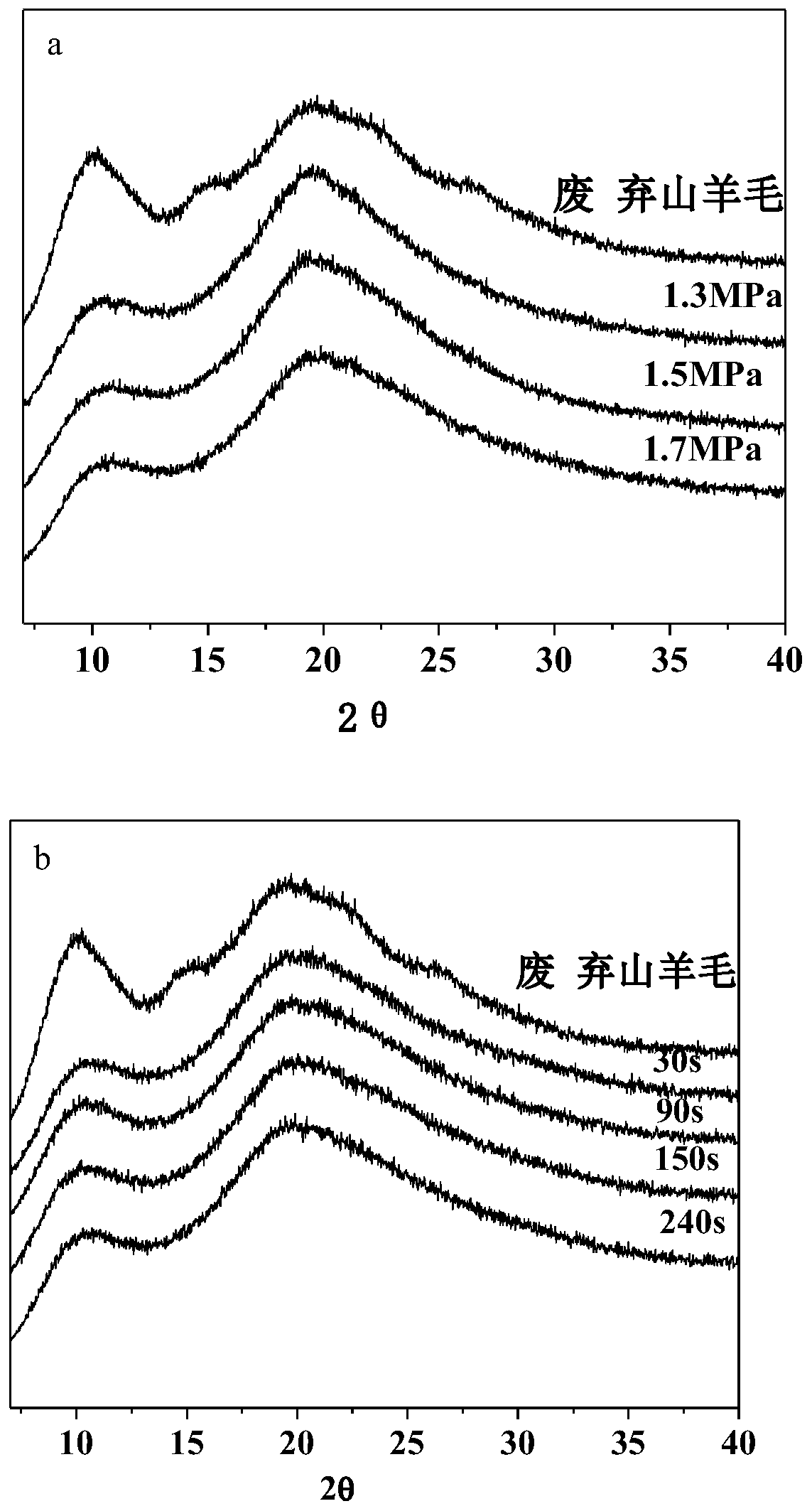

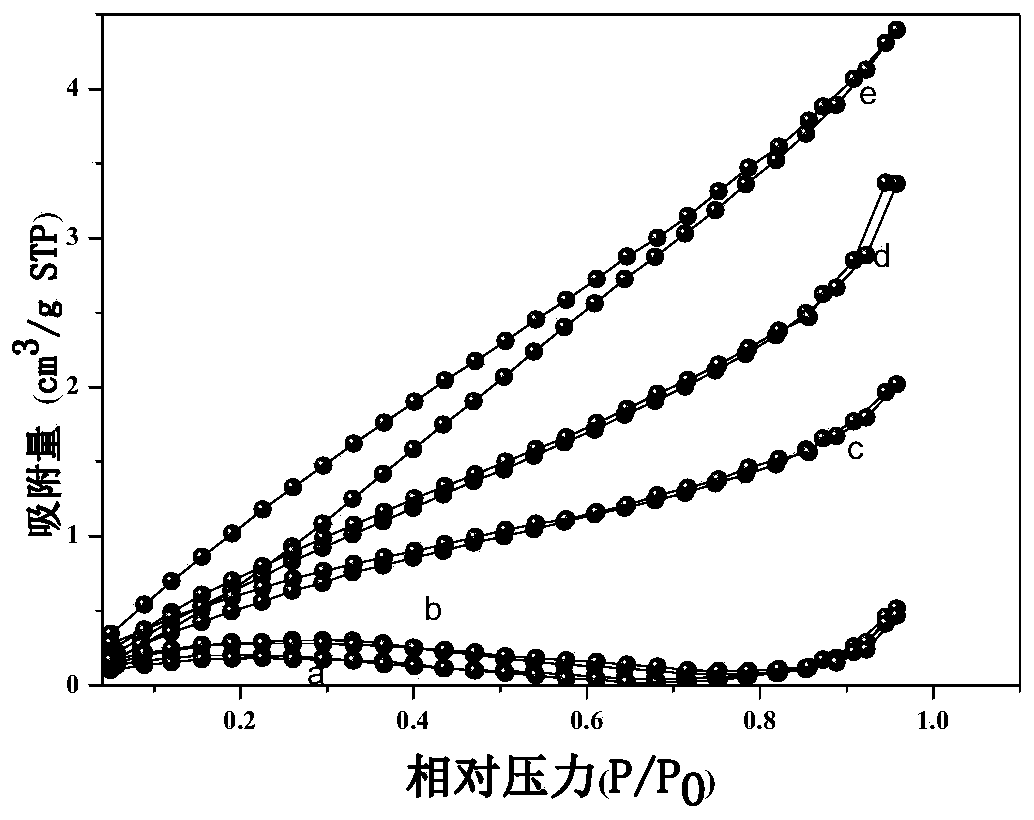

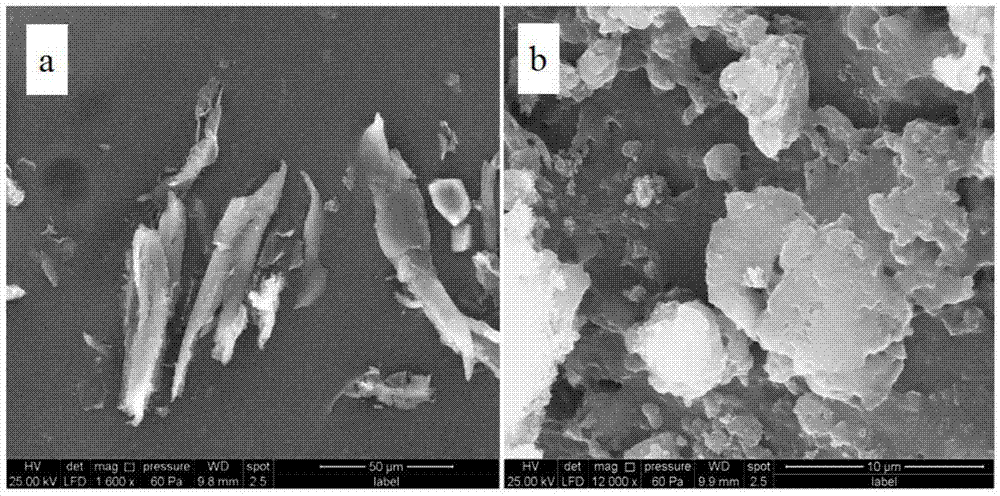

Method for preparing high-efficiency adsorbent for dyed wastewater from discarded goat wool

ActiveCN110237828AIncrease the amorphous regionImprove adsorption capacityOther chemical processesWater contaminantsWoolPre treatment

The invention discloses a method for preparing high-efficiency adsorbent for dyed wastewater from discarded goat wool, and belongs to the field of bio-based adsorption materials. The discarded goat wool is treated by adopting steam flash explosion and liquid nitrogen pulverization. According to the method provided by the invention, the steam flash explosion and liquid nitrogen pulverization technology adopted by the method is a high-efficiency environmentally-friendly pretreatment method, treated goat wool powder particles have a particle size as low as 20 [mu]m and a crystallization index as low as 2.6%, an amorphous region of the goat wool powder is increased, and the adsorption of the goat wool is facilitated; when the goat wool adsorbent prepared by adopting the method adsorbs dye in the dyed wastewater, the dye removal rate can be up to 95%, and the adsorption capability can be up to 426 mg / g, so that the goat wool adsorbent is an excellent biological adsorbent; and the goat wool adsorbent prepared by adopting the method can be used for repeated adsorption-desorption cycle for 5-6 times.

Owner:JIANGNAN UNIV

Dyeing method using natural pigment for cationic-modified linen fabric

InactiveCN109826024AIncrease the amorphous regionReduce forceDyeing processPre treatmentEnvironmental chemistry

The invention relates to a dyeing method for linen fabric, in particular to a dyeing method using natural pigment for cationic-modified linen fabric. The method aims at solving the problems of low coloring rate and low color fastness occurring when existing natural pigment is applied to linen fabric dyeing. The method includes the steps that firstly, the linen fabric is immersed into a cellulase solution for pretreatment with the cellulase solution; secondly, the linen fabric is subjected to retreatment with a cationic modifier solution; thirdly, a dye solution is prepared from natural pigmentdye; fourthly, the linen fabric obtained after retreatment is immersed into the dye solution for dyeing, and then dyeing of the linen fabric is completed. By means of the method, the dye uptake reaches 25%-50%, and the color fastness reaches 4-5 grade. The method is suitable for the field of printing and dyeing.

Owner:NORTHEAST FORESTRY UNIVERSITY

Method for preparing high-oil-absorption material from sawdust

InactiveCN104327189AIncrease the amorphous regionHigh reactivityOther chemical processesFiberOil retention

The invention discloses a method for preparing a high-oil-absorption material from sawdust. Fast-growing eucalyptus sawdust is used as a raw material. After activation pretreatment is carried out on sawdust fiber by the use of a stirred mil, p-methylbenzene sulfonic acid is used as a catalyst to carry out acetylization so as to obtain the sawdust high-oil-absorption material. The method is simple to operate and has a wide source of the raw material. So far, the used fast-growing eucalyptus sawdust has already been distributed in quantity in a number of provinces and cities of our country. Thus, production cost of the product can be reduced, and recycling and environmental protection of the raw material are realized. The oil-absorption material obtained can absorb multiple oils, has characteristics of high oil absorption multiple, fast oil absorption speed, good oil-water selectivity, high oil retention, reusability and the like, and can widely be used in processing pollution of oils on water surface and recycling oils in sewage.

Owner:YULIN NORMAL UNIVERSITY

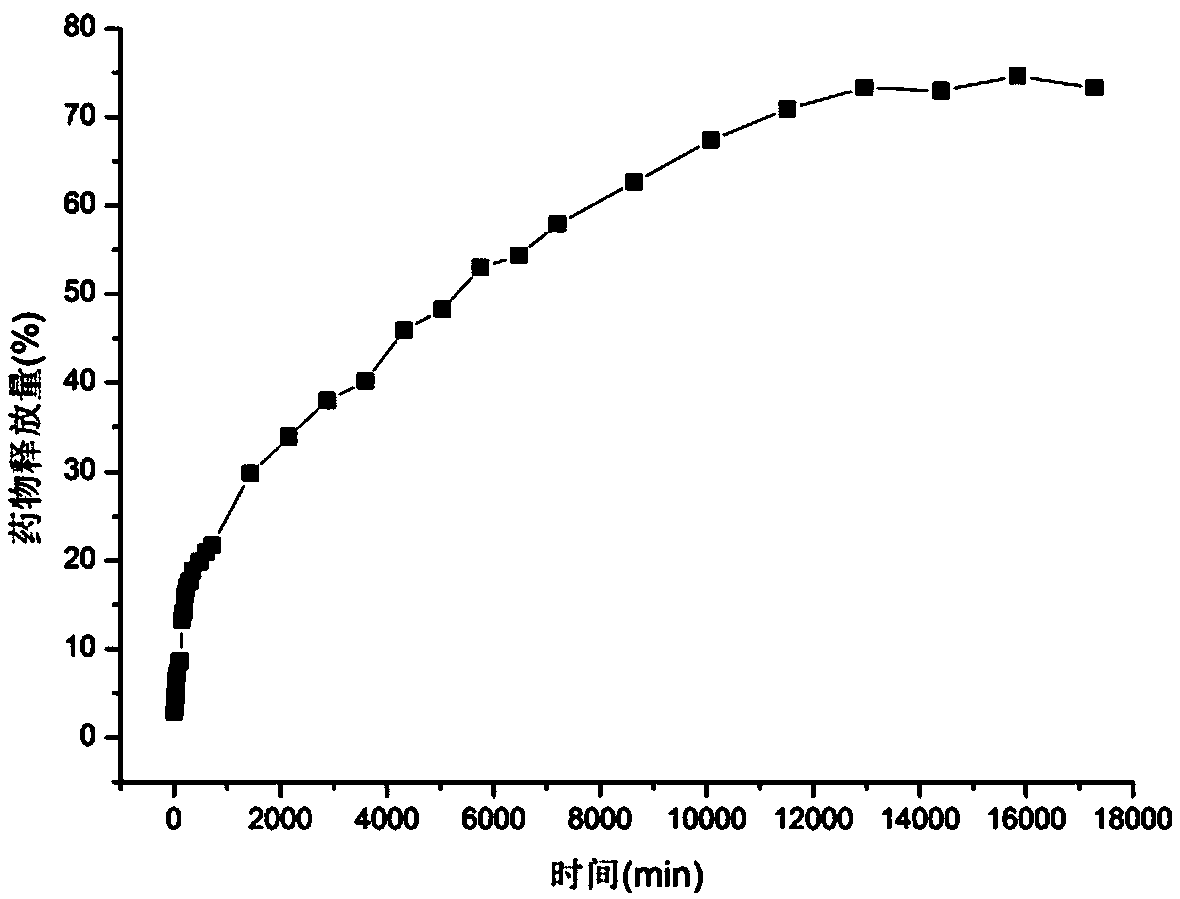

Processing method for enabling cellulose fibers to have anti-inflammatory function based on super-critical CO2 fluid technology

The invention relates to a processing method for enabling cellulose fibers to have an anti-inflammatory function based on a super-critical CO2 fluid technology. The processing method comprises the following steps: 1) carrying out pre-swelling or pre-treatment on the cellulose fibers; 2) adding an auxiliary agent to increase the solubility of an anti-inflammatory medicine in super-critical CO2 fluid, and directly dissolving a hydrophilic anti-inflammatory medicine which is not easily dissolved into the super-critical CO2 fluid by adopting a super-critical micro-emulsion / reversed micelle method;3) adding the anti-inflammatory medicine into a medicine groove of high-pressure equipment, eliminating air and introducing CO2; raising the pressure in a container to be 8 to 30MPa at the temperature of 32 to 120 DEG C to obtain the super-critical CO2 fluid, so as to immerse the cellulose fibers into the super-critical CO2 fluid; 4) dissolving the anti-inflammatory medicine in the super-criticalCO2 and enabling the anti-inflammatory medicine to enter the pre-swollen cellulose fibers; enabling drug-loading super-critical CO2 fluid and the cellulose fibers to continuously do relative movement; enabling the anti-inflammatory medicine to stay in an amorphous region in the cellulose fibers after pressure relief, so as to form drug-loading cellulose fibers capable of being slowly released.

Owner:SUZHOU UNIV +2

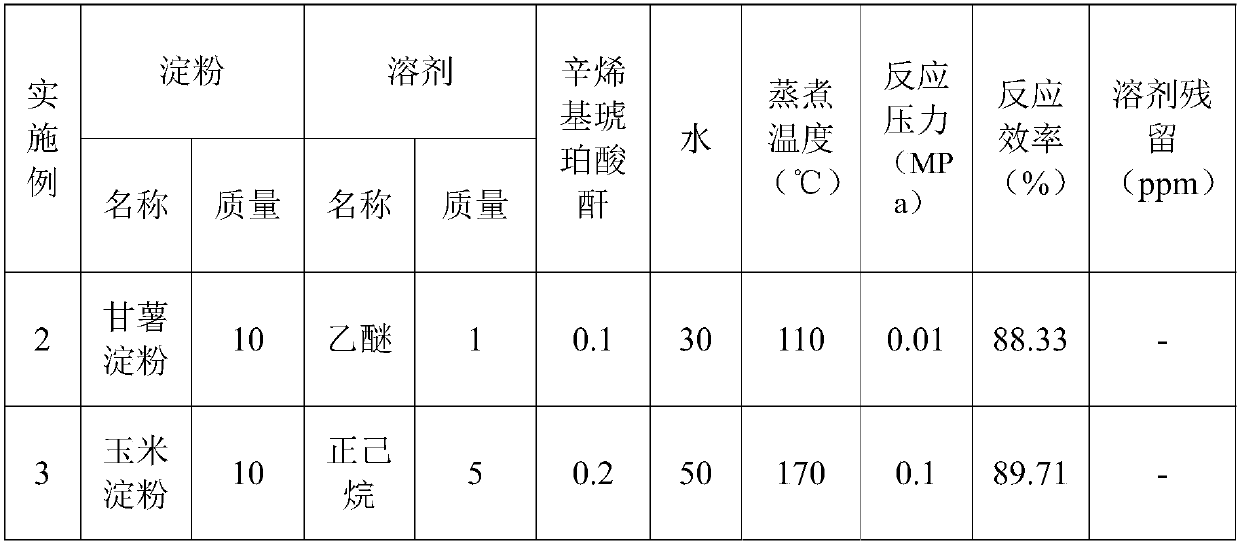

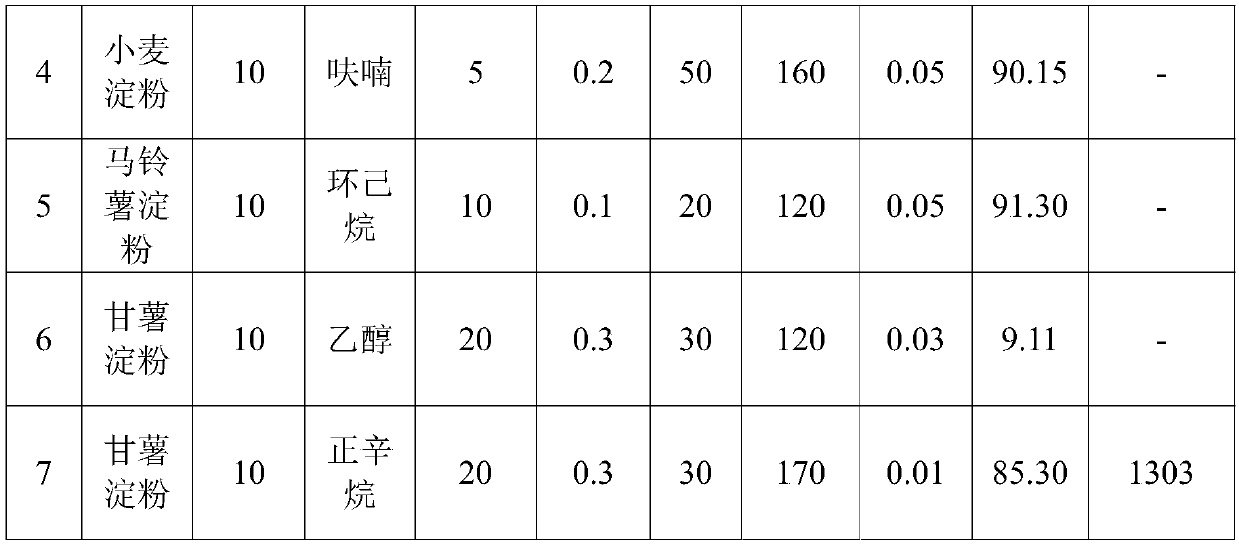

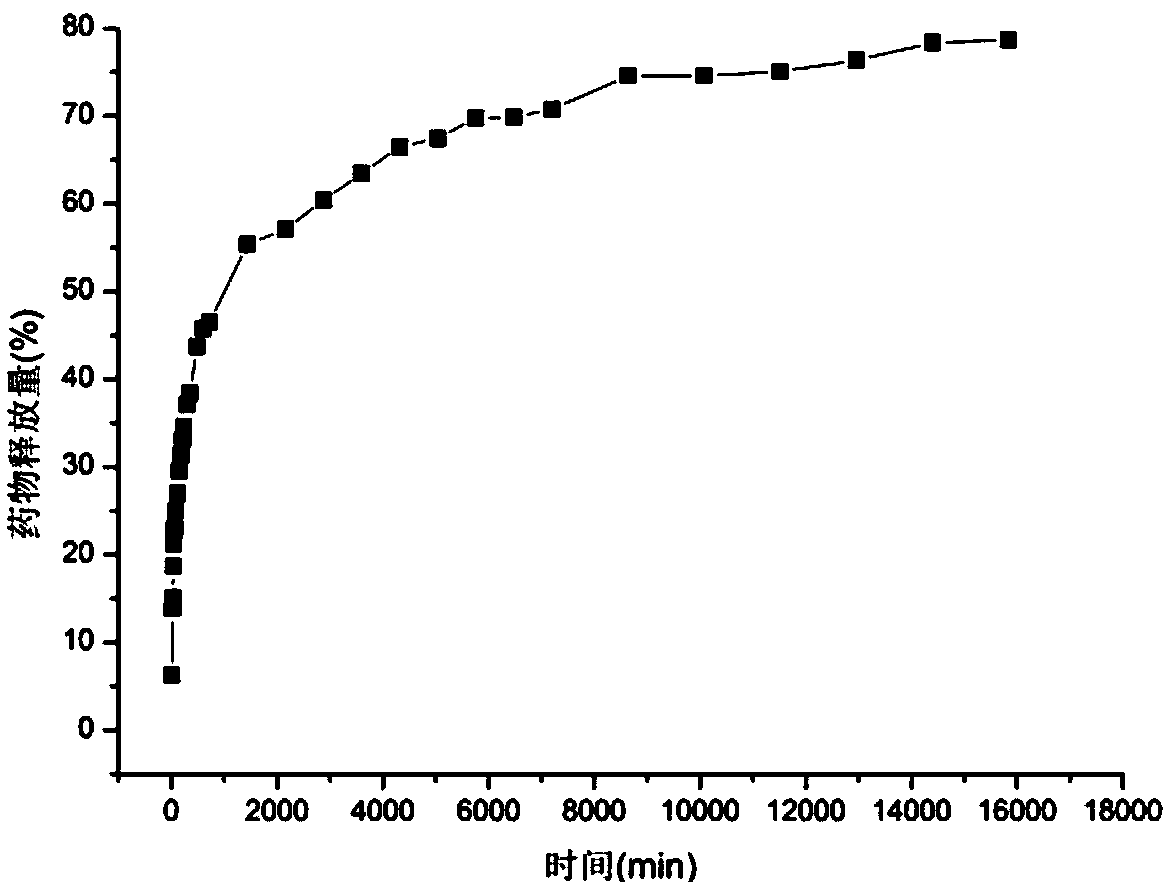

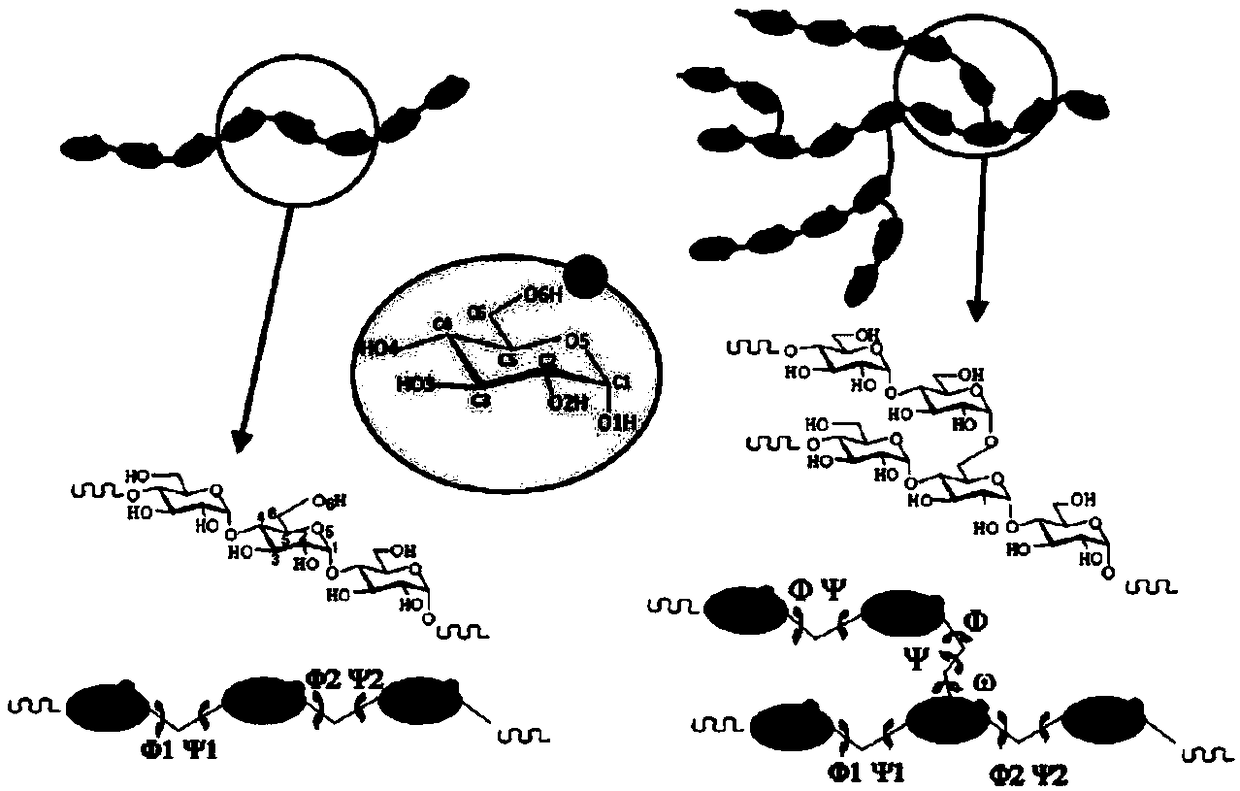

Method for preparing starch octenyl succinate and application of starch octenyl succinate

The invention discloses a method for preparing starch octenyl succinate. The method comprises the following steps of: carrying out injection cooking on pre-emulsion comprising starch, alkali, water, octenyl succinic anhydride and a low boiling solvent to obtain cooked slurry, and carrying out enzymatic hydrolysis to obtain the starch octenyl succinate. According to the method, reaction is carriedout under the condition of injection cooking and the action of high-temperature water vapor, so that intermolecular hydrogen bonds and crystal structures are rapidly destroyed; and due to the remarkable gelatinization process, starch molecular chains are sufficiently swollen, and the amorphous region of the starch is significantly increased. At the same time, the high temperature water vapor can also enable the low boiling solvent in the system to be rapidly removed; the octenyl succinic anhydride is rapidly and irregularly dispersed and separated out in the system, and is in full contact withstarch granules for reaction in the high-speed liquid flow state of an ejector, so that the octenyl succinic anhydride undergoes esterification reaction at various positions of the starch molecule, and a plurality of sites of the starch are significantly substituted; and the obtained starch octenyl succinate has relatively high substitution degree and emulsifying property.

Owner:ZHEJIANG NHU CO LTD +2

Processing method for enabling cellulose fibers to achieve antibacterial functions based on supercritical CO2 fluid technology

ActiveCN108716110AIncrease the amorphous regionGood slow releasePhysical treatmentBiochemical fibre treatmentSolubilityEmulsion

The invention relates to a processing method for enabling cellulose fibers to achieve antibacterial functions based on a supercritical CO2 fluid technology. The processing method includes the steps: 1) pre-swelling or pretreating the cellulose fibers; 2) adding auxiliaries to increase the solubility of antibacterial drugs in supercritical CO2 and indirectly dissolving hydrophilic antibacterial drugs not easily dissolved in the supercritical CO2 by a supercritical micro-emulsion / reverse micelle method; 3) adding the antibacterial drugs into a drug tank of high pressure equipment, eliminating air, leading in the CO2, increasing pressure in a container to 8-30MPa at the temperature of 32-120 DEG C to obtain supercritical CO2 fluids, and soaking the cellulose fibers in the supercritical fluids; 4) enabling the antibacterial drugs dissolved in the supercritical CO2 to enter the pre-swelled cellulose fibers, continuously performing relative movement of the drug-loaded supercritical CO2 fluids and the cellulose fibers, and enabling the decompressed antibacterial drugs to stay in amorphous areas inside the cellulose fibers to form the drug-loaded cellulose fibers capable of realizing slowrelease.

Owner:SUZHOU UNIV +2

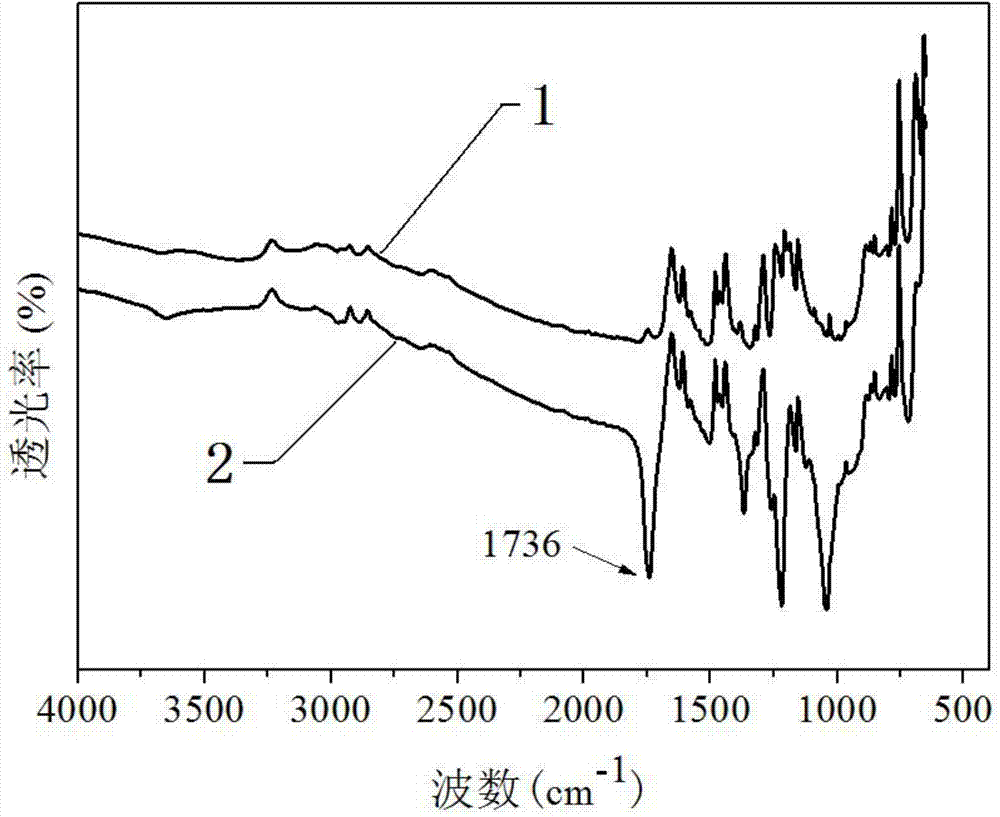

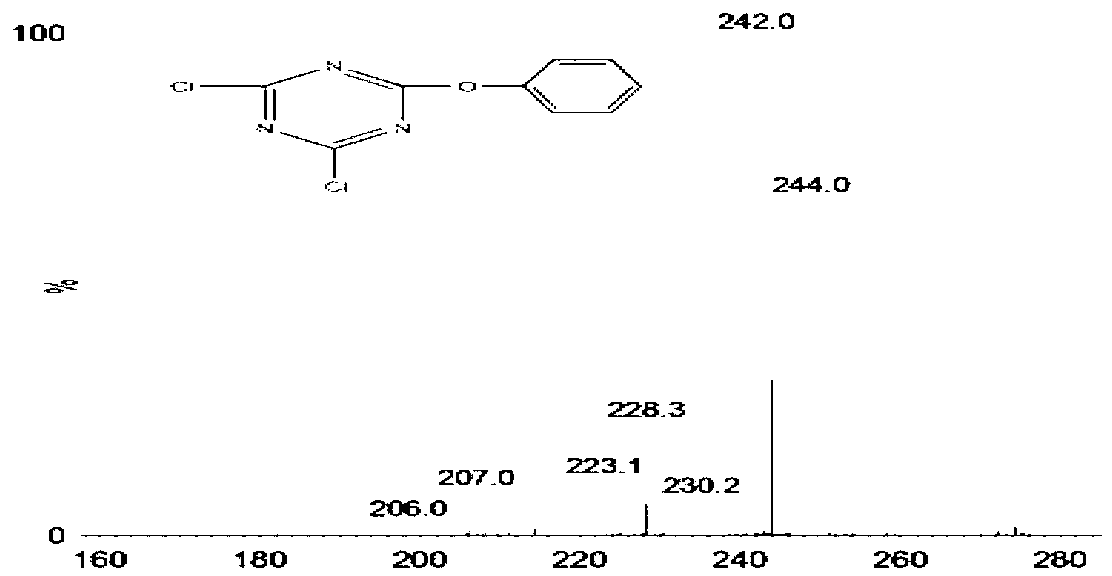

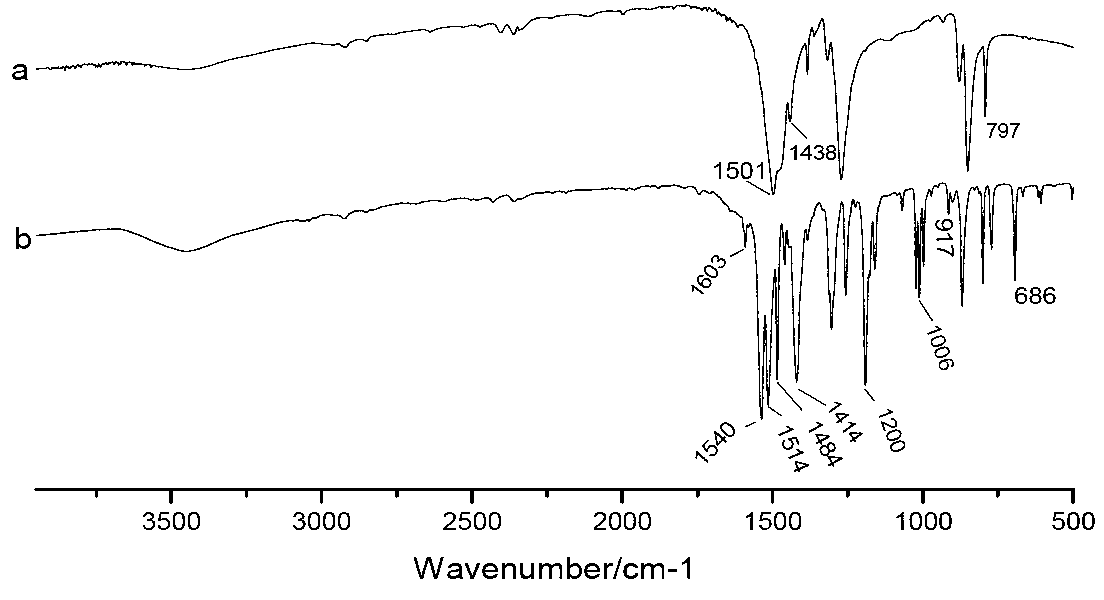

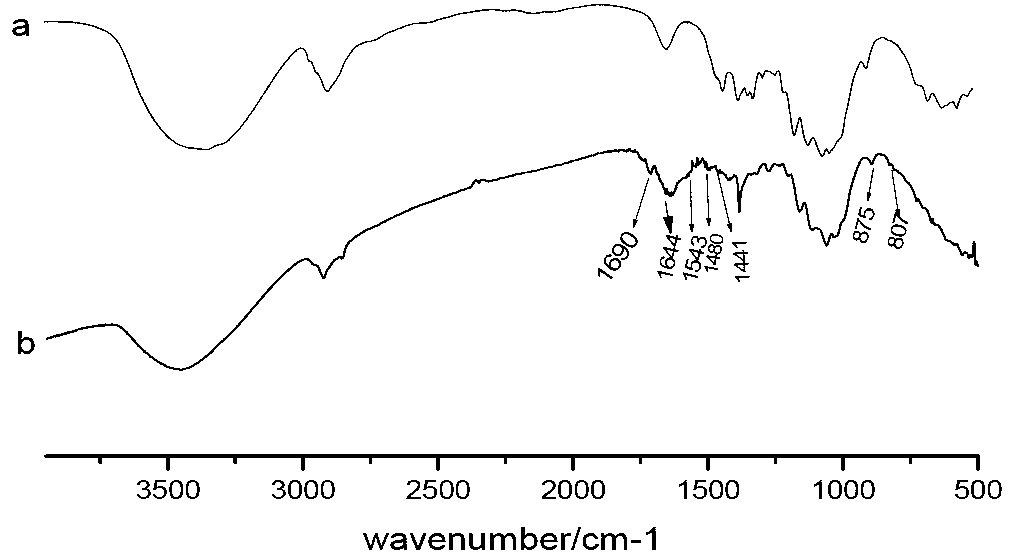

Method for improving hydrolytic efficiency of cellulose

The invention relates to a preparation method and an application of a cellulose modifier, particularly to a method for improving the hydrolytic efficiency of cellulose. The cellulose modifier of a triazine derivative is synthesized with cyanuric chloride serving as an active component and phenol, phenol-4-sulfonic acid or H acid monosodium salt serving as a functional component, and the structure of the modifier is presented through infrared spectrum and mass spectrum; and then the synthesized triazine derivative is used for modifying the cellulose and the modified microcrystalline cellulose is hydrolyzed in 8% of H2SO4 at a temperature of 130 DEG C for 5h. The result proves that when the relative mole content (by glucose ring) of the modifier is 16.67%, the yield of reducing sugar through hydrolysis of the cellulose is 23.54% maximally. Modification enables the crystalline structure of the microcrystalline cellulose to change through analysis of a wide angle X-ray diffraction pattern, amorphous regions are added, the crystallographic index is declined, and the grain size is reduced. The method has wide application prospect in hydrolysis of the cellulose.

Owner:高密银鹰新材料股份有限公司

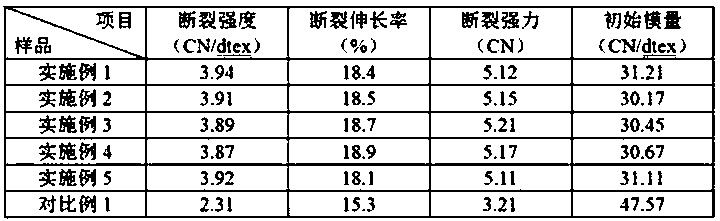

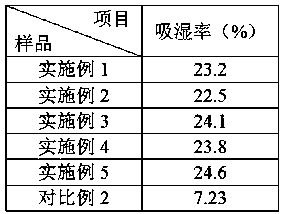

Biopolymer fiber and processing technology thereof

InactiveCN110344135AHigh breaking strengthEnhanced interactionConjugated cellulose/protein artificial filamentsArtificial filament heat treatmentPolyesterBiopolymer

The invention discloses a biopolymer fiber and a processing technology thereof. The biopolymer fiber is prepared from biopolymer polyester chips and cellulose nanocrystals by blend melt spinning. Interaction of biopolymer polyester chip molecules is enhanced by association hydrogen bonds formed among the cellulose nanocrystals and the biopolymer polyester chips, connecting bridges among biopolymerpolyester chip macromolecules are formed, relative slip of biopolymer polyester chip macromolecular chains is inhibited, so that the breaking strength of the biopolymer fiber is improved. As bio-based mixed polyols contain a large quantity of hydroxide radicals, hydrophilic groups are introduced into the prepared biopolymer polyester chip macromolecular chains, the hydrophilic performance of thebiopolymer polyester chips is improved, and hygroscopicity of the biopolymer fiber is improved. Experimental results indicate that the prepared biopolymer fiber has higher breaking strength, good toughness and mechanical performance and excellent hygroscopicity.

Owner:裴广华

Processing method for enabling cellulose fibers to achieve weight reducing function based on supercritical CO2 fluid technology

ActiveCN108716109AIncrease the amorphous regionGood slow releasePhysical treatmentVegetal fibresSolubilityEmulsion

The invention relates to a processing method for enabling cellulose fibers to achieve a weight reducing function based on a supercritical CO2 fluid technology. The processing method includes the steps: 1) pre-swelling or pretreating the cellulose fibers; 2) adding auxiliaries to increase the solubility of weight reducing drugs in supercritical CO2 and indirectly dissolving hydrophilic weight reducing drugs not easily dissolved in the supercritical CO2 by a supercritical micro-emulsion / reverse micelle method; 3) adding the weight reducing drugs into a drug tank of high pressure equipment, eliminating air, leading in the CO2, increasing pressure in a container to 8-30MPa at the temperature of 32-120 DEG C to obtain supercritical CO2 fluids, and soaking the cellulose fibers in the supercritical CO2; 4) enabling the weight reducing drugs dissolved in the supercritical CO2 to enter the pre-swelled cellulose fibers, continuously performing relative movement of drug-loaded supercritical CO2 fluids and the cellulose fibers, and enabling the decompressed weight reducing drugs to stay in amorphous areas inside the cellulose fibers to form the drug-loaded cellulose fibers capable of realizingslow release.

Owner:SUZHOU UNIV +3

Processing method for providing moisturizing function for cellulosic fibers based on supercritical CO2 fluid technology

ActiveCN108914599AIncrease the amorphous regionGood slow releaseVegetal fibresSolubilityPolymer science

The invention relates to a processing method for providing a moisturizing function for cellulosic fibers based on a supercritical CO2 fluid technology. The processing method comprises: 1) pre-swellingor pre-treating cellulose fibers, 2) adding an auxiliary agent to increase the solubility of a moisturizing agent in a critical CO2 fluid and treating a hydrophilic moisturizing agent hard to dissolve in supercritical CO2 through a supercritical microemulsion / reverse micelle method so that the hydrophilic moisturizing agent is indirectly dissolved in supercritical CO2, 3) adding the moisturizingagent in an agent tank of high pressure equipment, discharging air, feeding CO2 into the agent tank and increasing the pressure in the container to 8-30MPa at 32-120 DEG C to obtain supercritical CO2flows so that the cellulose fibers are immersed in the supercritical CO2 flows and 4) feeding the moisturizing agent dissolved in the supercritical CO2 flows into the pre-swollen cellulose fibers, continuously moving the agent-loading supercritical CO2 relative to the cellulose fibers and releasing the pressure so that the moisturizing agent stays in the amorphous region in the cellulose fiber andan agent-loading cellulose fiber capable of sustained release is formed.

Owner:SUZHOU UNIV +3

Supercritical CO2 fluid flash explosion treatment method of natural fibers and products of natural fibers

PendingCN111576060AIncrease freedomIncrease the amorphous regionSolvent-treatmentDyeing processNatural fiberProcess engineering

The invention discloses a supercritical CO2 fluid flash explosion treatment method for natural fibers and products of the natural fibers. The method comprises the following steps of filling dry natural fibers or natural fiber products into a flash explosion treatment unit according to a predetermined form, and transferring the flash explosion treatment unit into a flash explosion treatment device;connecting the flash explosion treatment device with a CO2 medium device, filling a CO2 medium into the flash explosion treatment device, and heating at the same time; when the modification treatmenttemperature and the modification treatment pressure in the flash explosion treatment device reach preset values, sequentially treating predetermined modification treatment time according to fluid circulation and fluid standing, and enabling the fluid to uniformly and sufficiently enter and to be distributed in the fiber inner phase; performing rapid pressure relief or instantaneous pressure relief on the flash explosion treatment device within the flash explosion time, and reducing the pressure in the flash explosion treatment device to the atmospheric pressure, thereby realizing flash explosion treatment of the dry natural fibers or the natural fiber products. The method is convenient to operate, simple in process, short in technological process, free of wastewater pollution and high intreatment efficiency.

Owner:山东出彩无水纤染高科有限公司 +3

Supercritical CO2 fluid technique based processing method for endowing cellulose fibers with skin whitening function

The invention relates to a supercritical CO2 fluid technique based processing method for endowing cellulose fibers with a skin whitening function. The method includes: 1) subjecting the cellulose fibers to pre-swelling or pretreatment; 2) adding auxiliary agents to increase solubility of skin whitening agents in supercritical CO2, adopting a supercritical microemulsion / reversed micelle method forindirectly dissolving hydrophilic skin whitening agents hardly dissoluble in supercritical CO2 into the supercritical CO2; 3) adding the skin whitening agents into an agent groove of high-pressure equipment, vacuumizing, feeding into CO2, raising the internal pressure of a vessel to 8-30MPa at 32-120 DEG C to obtain supercritical CO2 fluid, and soaking the cellulose fibers into the supercritical CO2; 4) enabling the skin whitening agents dissolved in the supercritical CO2 to enter the pre-swelled cellulose fibers, wherein the agent-carrying supercritical CO2 fluid and the cellulose fibers havecontinuous relative movement, and the anti-oxidation agents stay in amorphous regions of the cellulose fibers after pressure relief and form controlled-release agent-carrying cellulose fibers.

Owner:SUZHOU UNIV +3

Octenyl succinic starch ester preparation method

The invention discloses an octenyl succinic starch ester preparation method. The method includes: (1) subjecting alkaline dispersion liquid of starch and oil solution of octenyl succinic anhydride tojet cooking to obtain cooking liquor, or subjecting alkaline mixed liquid containing starch, octenyl succinic anhydride, water and grease to jet cooking to obtain cooling liquor; (2) standing the cooking liquor obtained in the step (1) to realize layering, taking lower emulsion, performing enzymolysis to obtain enzymolysis liquid, and subjecting the enzymolysis liquid to aftertreatment to obtain octenyl succinic starch ester. The preparation method is simple and efficient, and high replacement rate of the obtained octenyl succinic starch ester is achieved.

Owner:ZHEJIANG NHU CO LTD +2

A kind of wear-resistant high-impact nylon composite material and its preparation method and application

Owner:株洲时代工程塑料实业有限公司

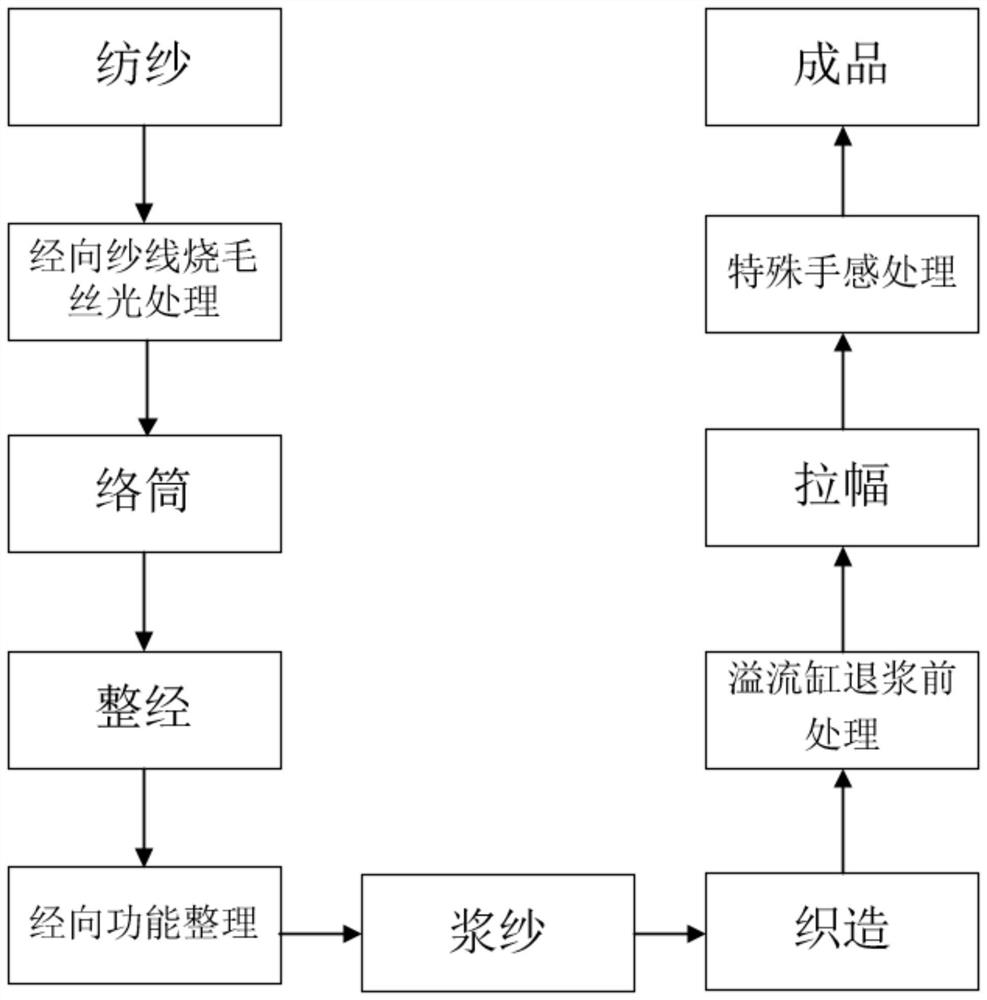

Fabric production process

PendingCN112030437AImprove qualityIncrease optionalityMercerising of yarns/threads/filamentsSingeingYarnTextile technology

The invention belongs to the technical field of textile, discloses a fabric production process, and aims to change an existing production process of white jeans and garment dyed fabric, improve the quality of the fabric and increase the style and function selectivity of the fabric. The fabric production process comprises the following steps of S1, spinning; S2, singeing and mercerizing of warp yarn; S3, spooling; S4, warping; S5, sizing; S6, weaving; S7, stentering; and S8, finished product obtaining. The step S2 specifically comprises the following sub-steps of S21, enabling single yarn to penetrate through a burner of a singeing machine in the warp direction, and burning off fuzz on the surface of the yarn; and S22, performing mercerizing treatment. According to the process, the dyeing yield of a finished product can be improved, and the finished product is glossy in surface, good in hand feeling and better in overall size stability.

Owner:洪英豪

A kind of preparation method of composite polymer electrolyte

ActiveCN107946640BEnhanced low temperature ionic conductivityPrevent crystallizationSecondary cellsAtom-transfer radical-polymerizationPolymer

The invention discloses a preparation method of composite polymer electrolyte. The preparation method of the composite polymer electrolyte includes: obtaining the composite polymer electrolyte through an ion-conducting agent; the preparation method of the ion-conducting agent includes: dissolving cuprous bromide powder and pentamethyldiethylenetriamine in an inert gas atmosphere Prepare catalyst solution in the first organic solvent; Monomer A dimethylaminoethyl methacrylate, monomer B di(ethylene glycol) methyl ether methacrylate and the first initiator are added to the catalyst solution respectively , and carry out atom transfer radical polymerization reaction at 75-85°C, and react for 10-60 minutes to obtain a reaction product; add excess cyclohexane to the reaction product to obtain a flocculent precipitate and purify to obtain an ion-conducting agent. The ion-conducting agent increases the amorphous region of the composite polymer electrolyte, can effectively inhibit the crystallization of the polymer matrix, thereby reducing the glass transition temperature, and then enhances the low-temperature ion conductivity of the composite polymer electrolyte.

Owner:JIANGHAN UNIVERSITY

A kind of high melting point biodegradable copolyester and preparation method thereof

The invention discloses a biodegradable copolyester with a high melting point and a preparation method thereof. The preparation method comprises the steps of putting terephthalic acid, butanediol, polyethylene glycol and a catalyst under vacuum conditions of 200-220°C and 60-80KPa React 4-6h to get reactant A; react adipic acid, isophthalic acid, butanediol and catalyst at 160-180°C and 60-80KPa vacuum conditions for 4-6h to get reactant B; reactant A And reactant B at 230-245 ℃, <100Pa vacuum conditions for 4-5h, in the system. The copolyester can effectively solve the problem of poor temperature resistance existing in the existing copolyester.

Owner:SICHUAN UNIV

Method for preparing sodium carboxymethylcellulose with degree of substitution from bagasse

The invention discloses a method for preparing sodium carboxymethylcellulose with the degree of substitution from bagasse. The method comprises the following steps of: performing ball-milling pretreatment on bagasse fibers, and etherifying bagasse cellulose and purifying. In the method, the bagasse fibers are subjected to the ball-milling pretreatment, so a lignin protective layer is broken, a crystalline structure of the cellulose is changed, an amorphous area of the bagasse cellulose is increased, and the reaction activity of the bagasse cellulose is improved; and by a subsequent series of methods and the optimization of control parameters, the degree of substitution of the prepared sodium carboxymethylcellulose is up to 1.5, the yield is 50 percent, the production cost is low, and a process is simple and environment-friendly.

Owner:YULIN NORMAL UNIVERSITY

Cotton fabric softening treatment method and application of phosphoric acid aqueous solution

PendingCN112553887AImprove the finishFibrous structure damageGrip property fibresVegetal fibresO-Phosphoric AcidCotton fibre

The invention provides a cotton fabric softening treatment method and application of a phosphoric acid aqueous solution. The cotton fabric softening treatment method comprises the following steps: 1)carrying out dipping treatment on cotton fabric by adopting the phosphoric acid aqueous solution with the concentration of 70-80wt%; 2) washing to be neutral; and 3) drying. The phosphoric acid aqueous solution with the proper concentration is adopted for treating the cotton fabric, the adopted phosphoric acid aqueous solution is non-toxic, harmless, low in cost and short in treatment process flow, but the softening treatment effect is almost the same as that of mercerizing pretreatment, the treated fiber structure is not damaged, the crystallinity of cotton fibers is slightly reduced, the amorphous area is increased, and the subsequent finishing and processing of the cotton fabric are facilitated.

Owner:LUOLAI LIFESTYLE TECH CO LTD +2

A supercritical co 2 Processing method of cellulose fiber with anti-oxidation function by fluid technology

ActiveCN108729218BIncrease the amorphous regionGood slow releaseVegetal fibresPharmaceutical drugCellulose fiber

The present invention relates to a kind of based on supercritical CO 2 Fluid technology makes cellulose fibers have anti-oxidation processing method, which includes: 1) pre-swell or pre-treat cellulose fibers; 2) add additives to increase the antioxidant drug in supercritical CO 2 Solubility in, for insoluble supercritical CO 2 The hydrophilic antioxidant drugs were indirectly dissolved in supercritical CO by the method of supercritical microemulsion / reverse micelles. 2 Middle; 3) Add antioxidant drugs into the drug tank of high-pressure equipment, remove air, and introduce CO 2 , at 32-120°C, raise the pressure inside the vessel to 8-30MPa to obtain supercritical CO 2 fluid, whereby the cellulose fibers are soaked in supercritical CO 2 Middle; 4) Antioxidant drugs dissolved in supercritical CO 2 into pre-swelled cellulose fibers, drug-loaded supercritical CO 2 There is constant relative movement between the fluid and the cellulose fiber, and the antioxidant drug stays in the amorphous region inside the cellulose fiber after the pressure is released, forming a drug-loaded cellulose fiber capable of slow release.

Owner:SUZHOU UNIV +2

Method for preparing acetate starch by mechanically activating solid phase reaction

The invention discloses a method for preparing acetate starch with mechanical activation solid phase reaction, comprising the following steps: a, mixing acetic anhydride equivalent to 40-80% of starch mass with starch, then adding solid sodium hydroxide equivalent to 1.0-4.0% of starch mass, stirring uniformly and then sealing for placing for 12-36h; b, loading a mixture obtained in the step a in a self-made ball-stirring mill, adding a ball milling medium with a ball material volume ratio of (6-12): 1, wherein the diameter of the ball milling medium is 4-8mm, stirring reaction lasts 40-80 min at the temperature of 40-80 DEG C, and the rotating speed of strirrer is 200-500 rpm; and c, separating the product with the ball milling medium, washing with ethanol with the volume fraction of 60-90% till the pH value is 6.0-7.0, vacuumizing and filtering, drying at the temperature of 30-60 DEG C, and then crashing till 100-120 meshed. According to the method, the acetate starch with high substitution value can be prepared, and the technology is simple and environmentally-friendly.

Owner:YULIN NORMAL UNIVERSITY +1

A supercritical co 2 Fluid technology makes cellulose fiber have slimming function processing method

ActiveCN108716109BIncrease the amorphous regionGood slow releasePhysical treatmentVegetal fibresPolymer sciencePharmaceutical drug

The present invention relates to a kind of based on supercritical CO 2 A processing method for making cellulose fibers have a weight-loss function by fluid technology, which includes: 1) pre-swelling or pre-treating cellulose fibers; 2 Solubility in fluid, for insoluble supercritical CO 2 The hydrophilic weight-loss drug uses the method of supercritical microemulsion / reverse micelles to dissolve it indirectly in supercritical CO 2 Middle; 3) Put the weight-loss medicine into the medicine tank of the high-pressure equipment, remove the air, and introduce CO 2 , at 32-120°C, raise the pressure inside the vessel to 8-30MPa to obtain supercritical CO 2 fluid, whereby the cellulose fibers are soaked in supercritical CO 2 Middle; 4) Weight-loss drugs are dissolved in supercritical CO 2 into pre-swelled cellulose fibers, and drug-loaded supercritical CO 2 There is constant relative movement between the fluid and the cellulose fiber, and the weight-loss drug stays in the amorphous area inside the cellulose fiber after the pressure is released, forming a drug-loaded cellulose fiber capable of slow release.

Owner:SUZHOU UNIV +3

A supercritical co 2 Fluid technology makes cellulose fibers have the processing method of repelling insects

ActiveCN108691201BIncrease the amorphous regionGood slow releaseVegetal fibresAnthelmintic drugPharmaceutical drug

The present invention relates to a kind of based on supercritical CO 2 A processing method for making cellulose fibers have an insect repellent function by fluid technology, which includes: 1) pre-swelling or pre-treating cellulose fibers; 2 Solubility in fluid, for insoluble supercritical CO 2 The hydrophilic anthelmintic drugs are indirectly dissolved in supercritical CO by the method of supercritical microemulsion / reverse micelles. 2 Middle; 3) Add the anthelmintic drug into the drug tank of the high-pressure equipment, remove the air, and introduce CO 2 , at 32-120°C, raise the pressure inside the vessel to 8-30MPa to obtain supercritical CO 2 fluid, whereby the cellulose fibers are soaked in supercritical CO 2 Middle; 4) Anthelmintic drugs dissolved in supercritical CO 2 into pre-swelled cellulose fibers, and drug-loaded supercritical CO 2 There is constant relative movement between the fluid and the cellulose fiber, and the anthelmintic drug stays in the amorphous area inside the cellulose fiber after the pressure is released, forming a drug-loaded cellulose fiber capable of slow release.

Owner:SUZHOU UNIV +3

High-melting-point biodegradable copolyester and preparation method thereof

The invention discloses a high-melting-point biodegradable copolyester and a preparation method thereof. The preparation method comprises the steps: subjecting terephthalic acid, butanediol, polyethylene glycol and a catalyst to reaction for 4-6 h under the vacuum conditions of 200-220 DEG C and 60-80 KPa so as to obtain a reactant A; reacting adipic acid, isophthalic acid, butanediol and a catalyst for 4-6 hours under the vacuum conditions of 160-180 DEG C and 60-80 KPa to obtain a reactant B; and reacting the reactant A and the reactant B at 230-245 DEG C under the vacuum condition of less than 100 Pa for 4-5 hours to obtain the copolyester. The copolyester can effectively solve the problem of poor temperature resistance of the existing copolyester.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com