Supercritical CO2 fluid flash explosion treatment method of natural fibers and products of natural fibers

A technology of natural fibers and treatment methods, which is applied in the field of flash explosion treatment of natural fibers and their products with a supercritical CO2 fluid, can solve the problems of less research on natural fiber modification, and achieve improved dyeing and finishing processing and dyeing performance Improved, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

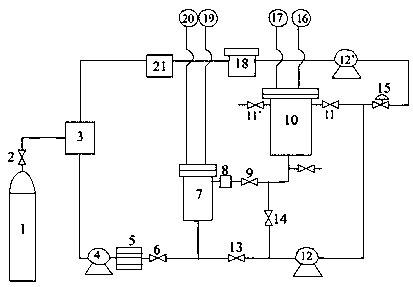

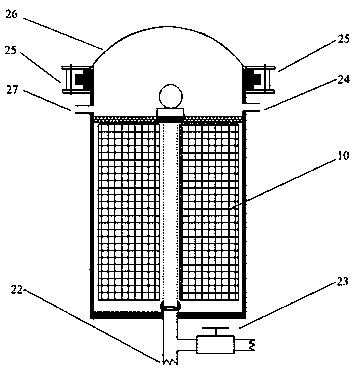

Method used

Image

Examples

Embodiment 1

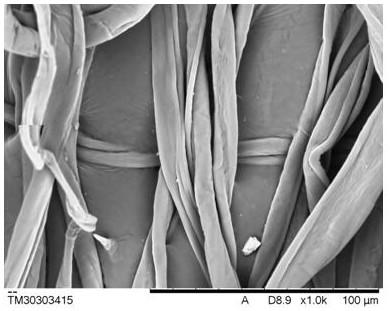

[0058] A certain amount of pure cotton fiber is subjected to flash explosion treatment. Place the sample in the fluid flash handling unit and close the system. Turn on the heating device, control the modification temperature at 100°C, and then introduce CO into the device 2 , the modification treatment pressure was controlled at 15MPa, and the modification treatment time was 30 min. According to the degree of flash explosion and requirements, the system parameters of the separation and recovery unit, such as temperature and pressure, are controlled at 20°C and 5 MPa. Then open the shut-off valve to quickly release the air, and the pressure relief time, that is, the flash explosion time is 8 s; then use an electron microscope to observe the changes in the surface morphology of the fiber before and after the fluid flash explosion, and the results are as follows Figure 3-Figure 6 shown.

[0059] image 3 , Figure 4 It is the original electron microscope picture of cotton f...

Embodiment 2

[0062] A certain amount of pure wool fiber is subjected to flash explosion treatment. Place the sample in the flash explosion treatment unit and close the system. Turn on the heating device, control the modification temperature at 100°C, and then introduce CO into the device 2 , the control modification treatment pressure is 15MPa, and the modification treatment time is 30 min. According to the degree of flash explosion and requirements, the system parameters of the separation and recovery unit, such as temperature and pressure, are controlled at 20°C and 5 MPa. Then open the stop valve to quickly deflate, the pressure relief time is 8s; then use the cold field electron microscope to observe the change of its surface morphology before and after the fluid flash, the results are as follows Figure 7-Figure 9 shown.

[0063] Figure 7 This is the original electron micrograph of the wool fiber under the scanning electron microscope. It can be seen that when the wool fiber has ...

Embodiment 3

[0066] A certain amount of wool fabric is subjected to flash explosion treatment. Place the sample in the processing unit and close the system. Turn on the heating device, control the modification temperature at 100°C, and then introduce CO into the device 2 , the control modification treatment pressure is 15 MPa, and the modification treatment time is 30 min. According to the degree of flash explosion and requirements, the system parameters of the separation and recovery unit, such as temperature and pressure, are controlled at 20°C and 5 MPa. Then open the shut-off valve to deflate quickly, and the deflation time is 8s; then use a cold-field electron microscope to observe the changes in the surface morphology before and after the flash explosion, and the results are as follows Figure 10 with Figure 11 shown.

[0067] Figure 10 It is the original picture of the wool fabric under the scanning electron microscope. It can be seen that the surface of the single fiber of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com