Cotton fabric softening treatment method and application of phosphoric acid aqueous solution

A phosphoric acid aqueous solution, softening technology, applied in fiber processing, plant fibers, textiles and papermaking, etc., can solve problems such as danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

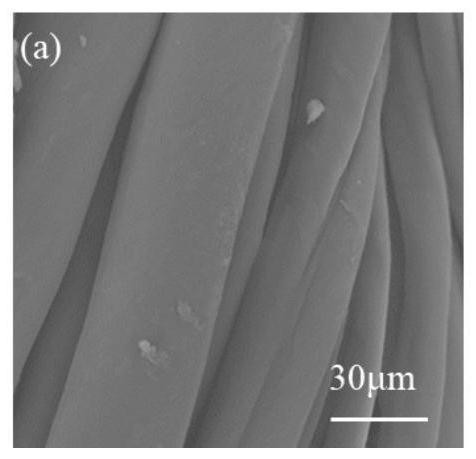

[0032] The method for cotton fabric softening treatment in the present embodiment, comprises the steps:

[0033] 1) Solution preparation: Add a commercially available phosphoric acid aqueous solution with a mass M of 85 wt% concentration into water, and stir while adding to make it evenly mixed to obtain a phosphoric acid aqueous solution with a concentration of 75 wt%. Volume of water required to prepare the solution: H 2 O(mL)=85M / 75-M;

[0034] 2) Immersion treatment: soak the cotton fabric in 75wt% phosphoric acid aqueous solution for 10 minutes after wetting; the fabric is completely immersed in the solution, and the fabric can be stirred several times during the immersion process to make it contact more fully, and the treatment temperature is 30°C; Wherein, the mass ratio of cotton fabric to 75wt% phosphoric acid aqueous solution is 1:50.

[0035] 3) Water washing: After the impregnation is completed, the fabric is taken out, soaked in water for 5 minutes, and then rin...

Embodiment 2

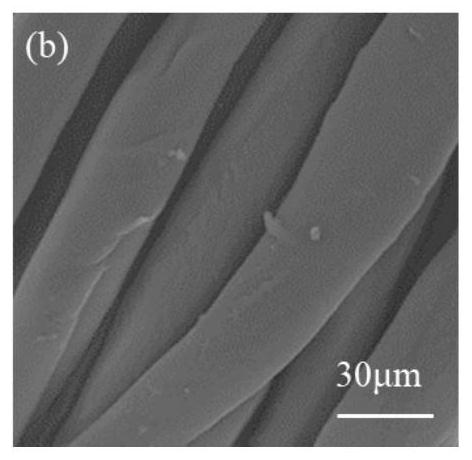

[0038] Cotton fabric softening pretreatment method in the present embodiment may further comprise the steps:

[0039] 1) Solution preparation: Add a commercially available phosphoric acid solution with a mass of M and a concentration of 85wt% into water, and stir while adding to make it evenly mixed to obtain a phosphoric acid solution with a concentration of 75wt%. Volume of water required to prepare the solution: H 2 O(mL)=85M / 75-M

[0040] 2) Immersion treatment: soak the cotton fabric in 75wt% phosphoric acid aqueous solution for 10 minutes after wetting; the fabric is completely immersed in the solution. Wherein, fabric: the mass ratio of solution is 1:50.

[0041] 3) Water washing: After the impregnation is completed, take out the fabric, soak it in water for 5 minutes, and then rinse until the surface of the fabric is neutral, which can be tested with pH test paper.

[0042] 4) Drying: Put the washed fabric into an oven for drying. The temperature is 80°C and the ti...

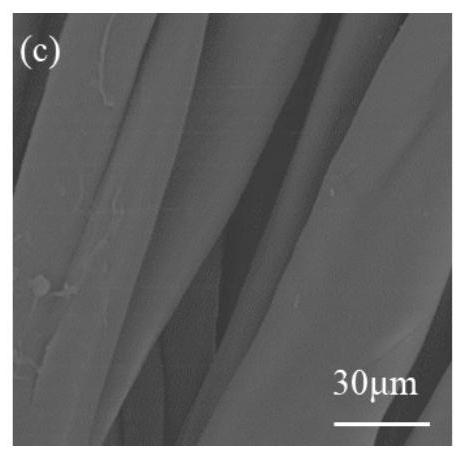

Embodiment 3

[0044] 1) Solution preparation: Add a commercially available phosphoric acid aqueous solution with a mass M of 85 wt% concentration into water, and stir while adding to make it evenly mixed to obtain a phosphoric acid aqueous solution with a concentration of 75 wt%. Volume of water required to prepare the solution: H 2 O(mL)=85M / 75-M

[0045] 2) Dipping treatment: soak the cotton fabric in 75wt% phosphoric acid aqueous solution for 15 minutes after wetting, the fabric is completely immersed in the solution, the fabric can be stirred several times during the dipping process to make it more fully contacted, and the treatment temperature is 30°C; Wherein, the mass ratio of cotton fabric to 75wt% phosphoric acid aqueous solution is 1:50.

[0046] 3) Water washing: After the impregnation is completed, the fabric is taken out, soaked in water for 5 minutes, and then rinsed until the surface of the fabric is neutral, which can be tested with pH test paper.

[0047] 4) Drying: Put t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com