Method for preparing high-efficiency adsorbent for dyed wastewater from discarded goat wool

A technology for dyeing wastewater and goat hair, which is applied in chemical instruments and methods, textile industry wastewater treatment, adsorption water/sewage treatment, etc., can solve the problems of non-environmental protection, high cost, and complicated modification methods, and achieve the purpose of increasing amorphous zone effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

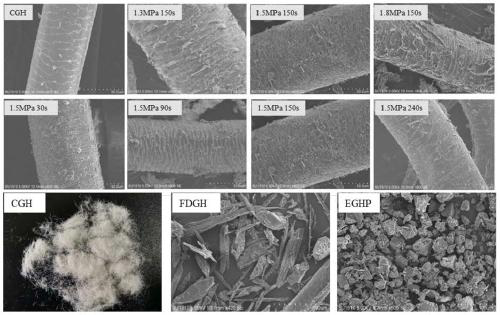

[0033] Using steam flash explosion and liquid nitrogen crushing technology to process waste goat hair, the specific steps are as follows:

[0034] Step 1: Pretreatment of waste goat hair by steam flash explosion:

[0035] (1) Carry out steam flash explosion on waste goat hair, the steam flash explosion pressure is 1.5MPa, and the steam flash explosion time is 150s;

[0036] (2) adopt 200 mesh sieves, filter and remove the water in the goat hair after steam flash explosion;

[0037] (3) Put the sample after steam flash explosion into -80°C ultra-low temperature refrigerator to freeze for 2 hours, then dry the goat hair by vacuum freeze-drying method, the vacuum degree is 9.5Pa, the temperature is -50°C, and the drying time is 48h;

[0038] Step 2: Liquid nitrogen freezing and crushing: The flash-exploded and dried goat hair is crushed with liquid nitrogen to obtain a goat hair powder with a particle size of 20 μm. The goat hair is small in size and has small voids inside, so i...

Embodiment 2

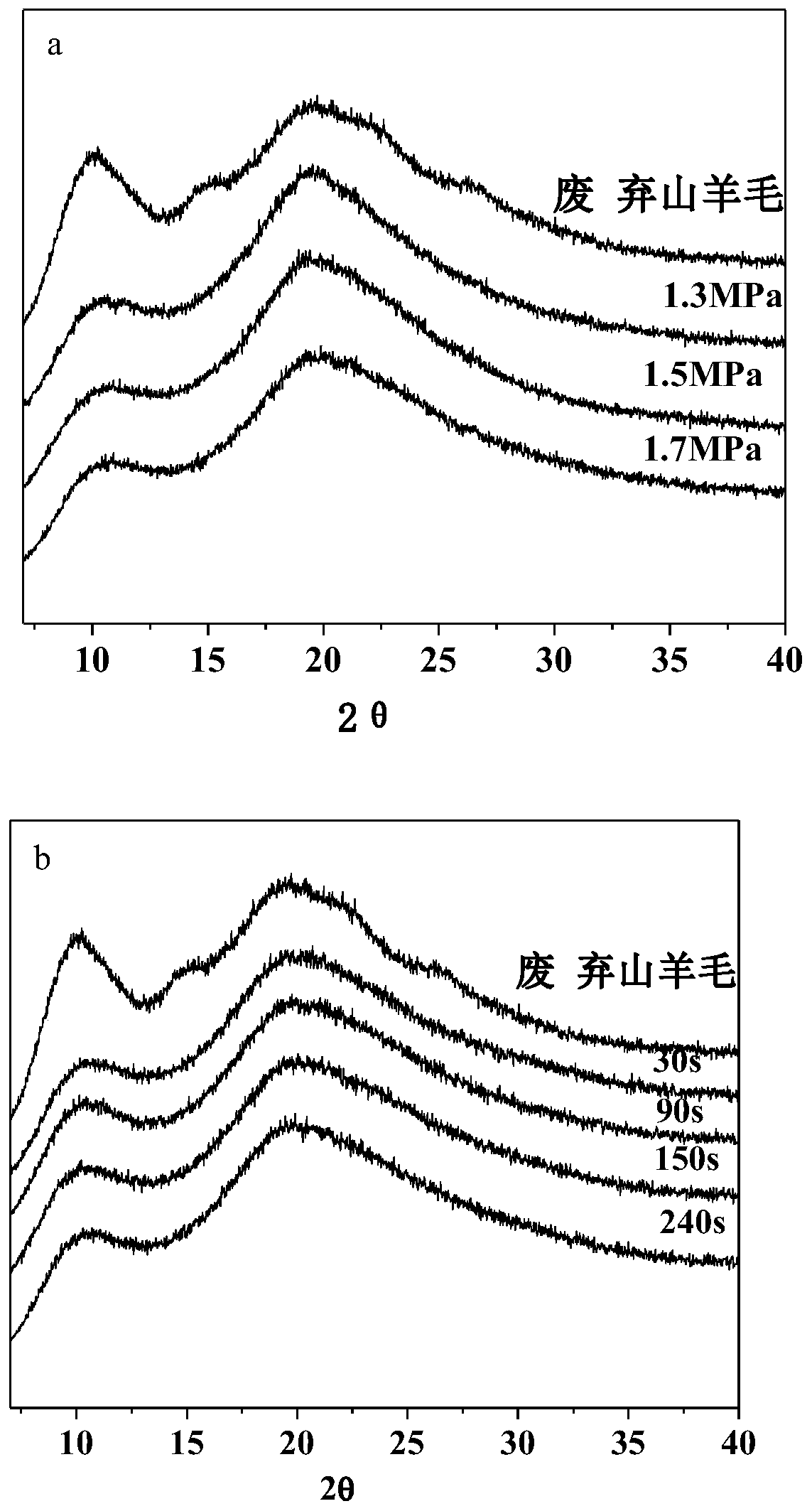

[0042] Embodiment 2: the influence of different steam flash explosion conditions on the performance of goat hair powder

[0043] 1. Effects of different flash explosion pressures on the properties of goat wool:

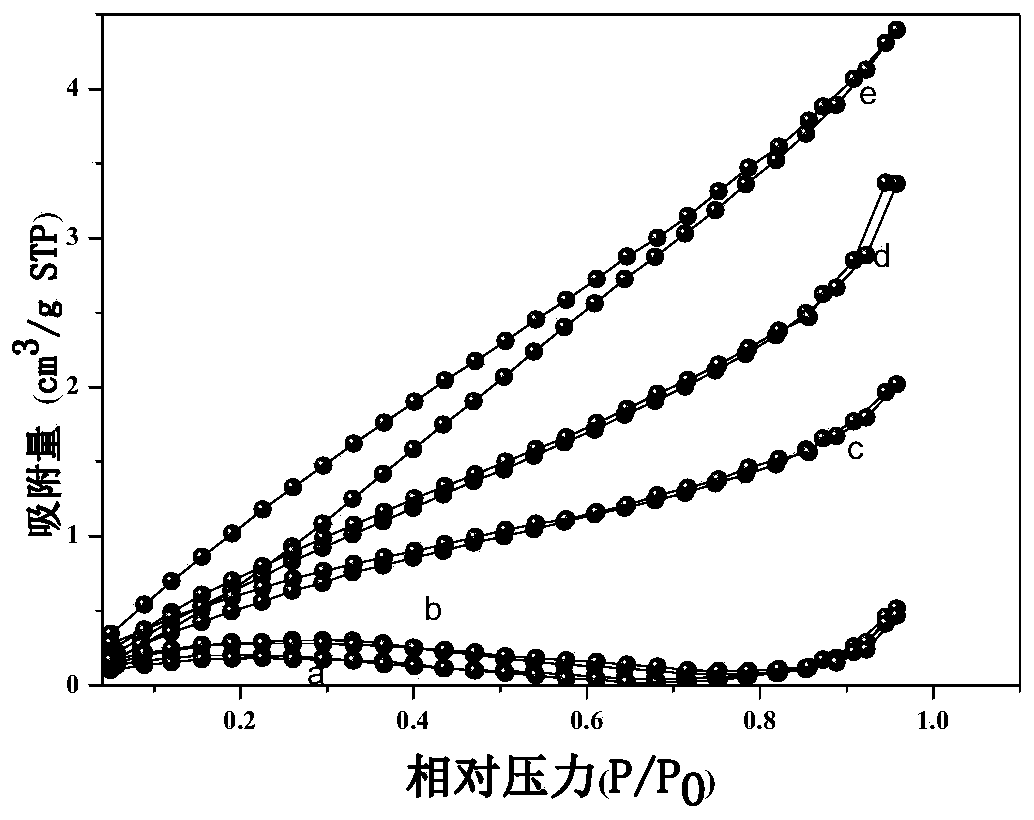

[0044] Adopt the method of embodiment 1 to process waste goat hair, the only difference is that the steam flash explosion pressure is 1.3MPa and 1.7MPa respectively, the particle size of the goat hair obtained after treatment is about 36 μ m and 18 μ m respectively, the adsorption performance and crystallization of goat hair index see Figure 4 And Table 1 and Table 2.

[0045] 2. The influence of different flash explosion time on the performance of goat wool:

[0046] Adopt the method of embodiment 1 to process waste goat hair, the only difference is that the steam holding time is 30s, 90s and 240s respectively, the particle size of the goat hair obtained after the treatment is respectively 42 μm, 38 μm, 19 μm, the adsorption performance of goat hair and Crystalli...

Embodiment 3

[0052] Embodiment 3: the reuse of goat hair adsorbent.

[0053] Desorption and repeated adsorption of the goat hair sorbent consisted of the following steps:

[0054] (1) Wash the goat hair after dye adsorption in 0.1g / L NaOH for 30min to achieve desorption;

[0055] (2) Wash the desorbed goat hair with deionized water until neutral, and freeze-dry the collected desorbed goat hair again;

[0056] (3) The goat hair after desorption is repeatedly adsorbed, and the adsorption condition is the same as step three in Example 1, and the results are as follows Image 6 shown. The goat hair adsorbent can repeat the cycle of adsorption and desorption for 5-6 times.

[0057] Depend on Figure 5 It can be seen that the goat hair adsorbent can repeat the adsorption and desorption cycle for 5-6 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com