Biopolymer fiber and processing technology thereof

A technology of biomass fiber and processing technology, which is applied in the direction of cellulose/protein conjugated artificial filament, conjugated synthetic polymer artificial filament, heat treatment of artificial filament, etc., which can solve the problem of high brittleness of biomass fiber and the limitation of industrialization Application, minimum demand gap and other issues, to achieve the effect of increasing intermolecular pores, promoting sustainable development, and accelerating thermal movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

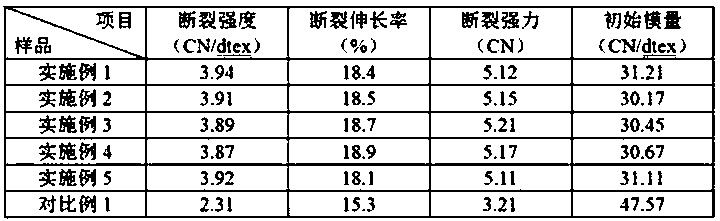

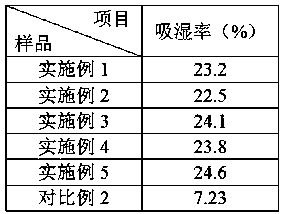

Embodiment 1

[0035] A kind of biomass fiber, the biomass fiber is prepared by blending melt spinning of biomass polyester chips and cellulose nanocrystals, the weight ratio of biomass polyester chips and cellulose nanocrystals is 8:1; Substance Polyester chips are prepared from the following raw materials in parts by weight: 20 parts of bio-based succinic acid, 20 parts of bio-based mixed polyols, 20 parts of sodium 1,4-dihydroxybutane-2-sulfonate and 0.001 parts of nickel catalyst cellulose nanocrystals are prepared from the following raw materials in parts by weight: 10 parts of microcrystalline cellulose and 1 part of concentrated sulfuric acid; bio-based mixed polyols are ethylene glycol, 1,2-propylene glycol, 1,2-butane A mixture of diol, pentylene glycol and sorbitol, the weight ratio of ethylene glycol, 1,2-propanediol, 1,2-butanediol, pentylene glycol and sorbitol is 100:0.5:0.2:0.1:0.1.

[0036] Adopt above-mentioned raw material to process a kind of biomass fiber, the processing ...

Embodiment 2

[0042] A kind of biomass fiber, this biomass fiber is prepared by blending melt spinning by biomass polyester chip and cellulose nanocrystal, the weight ratio of biomass polyester chip and cellulose nanocrystal is 8.5:1; Substance Polyester chips are prepared from the following raw materials in parts by weight: 22 parts of bio-based succinic acid, 25 parts of bio-based mixed polyols, 22 parts of sodium 1,4-dihydroxybutane-2-sulfonate and 0.0015 parts of iron catalyst cellulose nanocrystals are prepared from the following raw materials in parts by weight: 12 parts of microcrystalline cellulose and 1.2 parts of concentrated sulfuric acid; bio-based mixed polyols are ethylene glycol, 1,2-propylene glycol, 1,2-butane A mixture of diol, pentylene glycol and sorbitol, the weight ratio of ethylene glycol, 1,2-propanediol, 1,2-butanediol, pentylene glycol and sorbitol is 100:1:0.6:0.2:0.2.

[0043] Adopt above-mentioned raw material to process a kind of biomass fiber, the processing t...

Embodiment 3

[0049] A kind of biomass fiber, the biomass fiber is prepared by blending melt spinning of biomass polyester chips and cellulose nanocrystals, the weight ratio of biomass polyester chips and cellulose nanocrystals is 9:1; Substance Polyester chips are prepared from the following raw materials in parts by weight: 25 parts of bio-based succinic acid, 30 parts of bio-based mixed polyols, 25 parts of sodium 1,4-dihydroxybutane-2-sulfonate and 0.01 parts of manganese catalyst cellulose nanocrystals are prepared from the following raw materials in parts by weight: 15 parts of microcrystalline cellulose and 1.5 parts of concentrated sulfuric acid; bio-based mixed polyols are ethylene glycol, 1,2-propylene glycol, 1,2-butane A mixture of diol, pentylene glycol and sorbitol, the weight ratio of ethylene glycol, 1,2-propanediol, 1,2-butanediol, pentylene glycol and sorbitol is 100:3:1:2:0.5.

[0050] Adopt above-mentioned raw material to process a kind of biomass fiber, the processing t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com