Method for preparing starch octenyl succinate and application of starch octenyl succinate

A technology of octenyl succinic acid and octenyl succinic anhydride, applied in the field of food chemistry, can solve the problems of long reaction time, high pH value control requirements, and difficult quality control, etc., and achieve high substitution rate of esterification reaction , short reaction time, high emulsifying performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

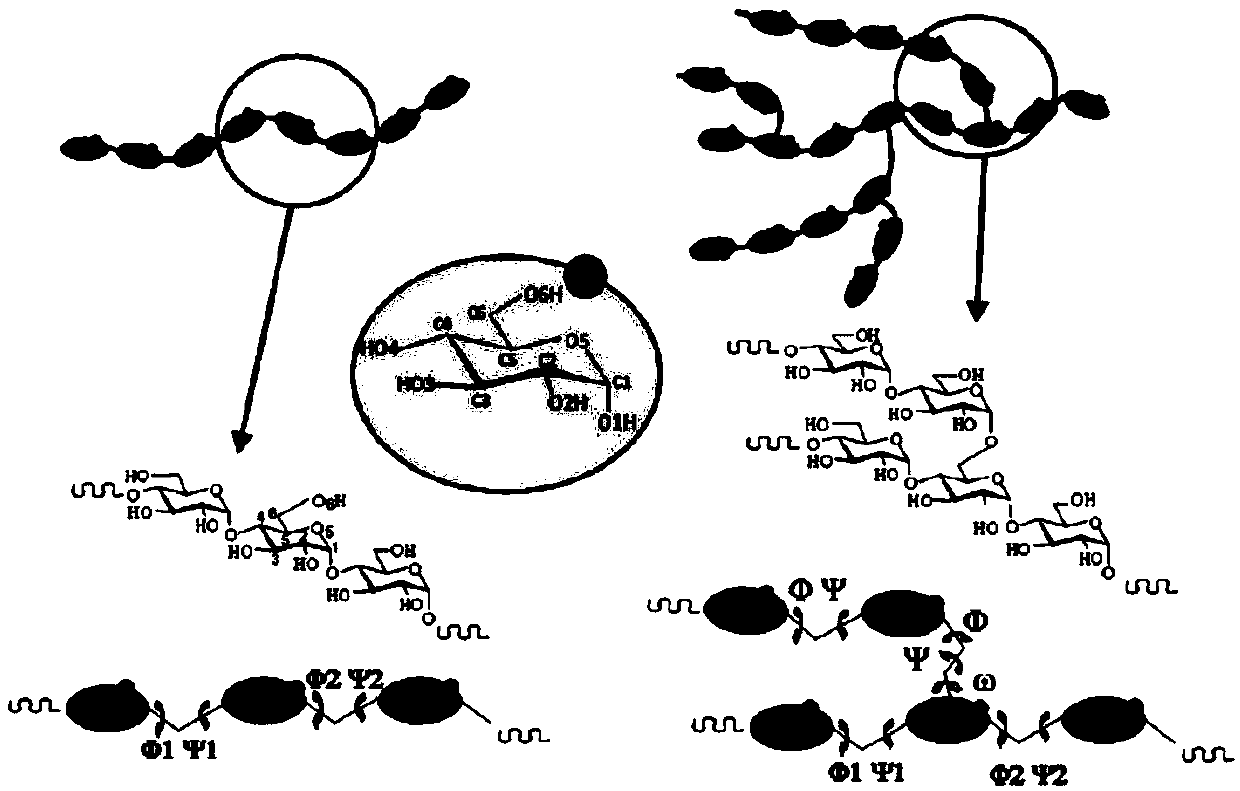

Method used

Image

Examples

Embodiment 1

[0034] 1) 10kg of sweet potato starch, 0.06kg of sodium hydroxide, and 30kg of water are quickly stirred for 10min to obtain a dispersion; 0.3kg of octenyl succinic anhydride is dissolved in 20kg of ether to obtain an octenyl succinic anhydride solution.

[0035] 2) Pass the dispersion and the octenyl succinic anhydride solution into a static mixer for emulsification at a temperature of 20°C and a residence time of 20s to obtain a pre-emulsion;

[0036] 3) Control the steam temperature in the ejector to 120°C, the feed rate is 100kg / h, and pump the pre-emulsion into the ejector for jet cooking to obtain the cooking slurry;

[0037] 4) Add 50KU α-amylase to the obtained slurry, and carry out enzymatic hydrolysis at 40°C for 20 minutes.

[0038] Then adjust the pH to 3 to kill the enzyme, and then adjust the pH of the enzymatic hydrolysis material back to 6; then centrifuge the enzymatic hydrolysis material, filter, and spray dry to obtain uniformly substituted starch octenyl succinate. ...

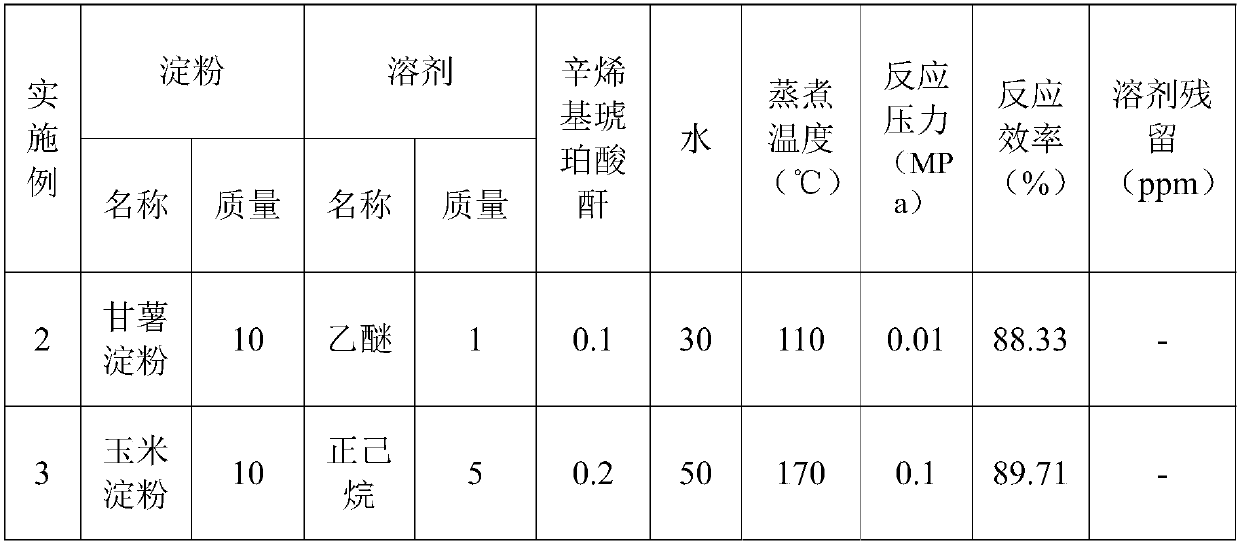

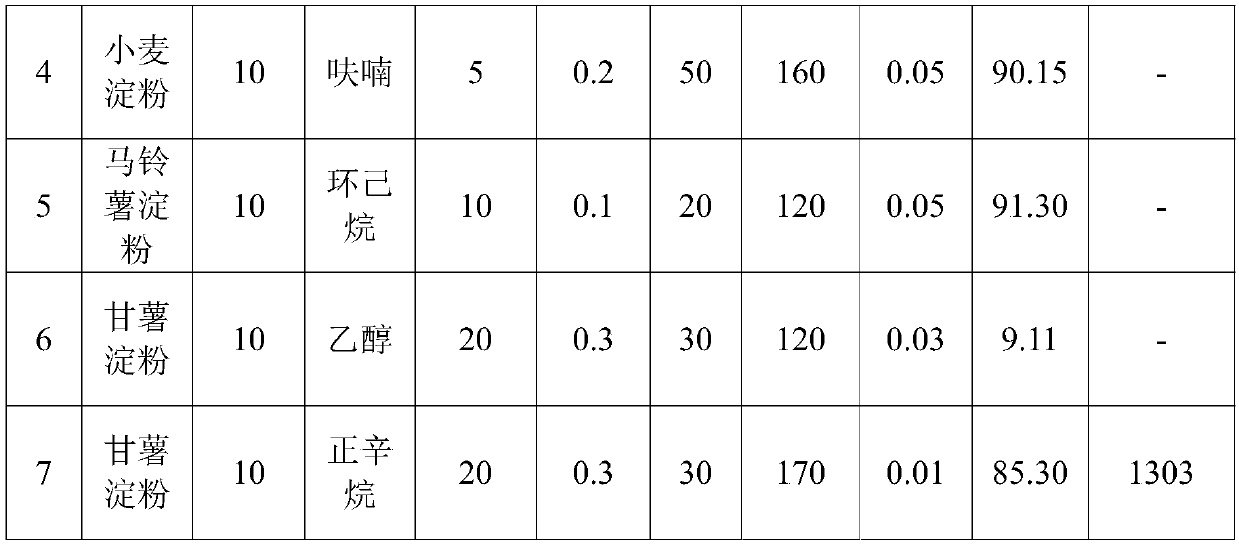

Embodiment 2-7

[0040] According to the method of Example 1, adjust the type and amount of starch, the type and amount of fat, the amount of octenyl succinic anhydride and water, the cooking temperature, the feed rate and other parameters. Other conditions are the same as in Example 1, and the result is obtained As follows (the unit of mass in the table is kg; the-symbol in the table means that no solvent residue is detected):

[0041]

[0042]

Embodiment 6

[0043] The side reaction of ethanol and octenyl succinic anhydride in Example 6 resulted in a significant reduction in the reaction efficiency of forming starch esters.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com