Method for preparing high-oil-absorption material from sawdust

A technology of high oil absorption and wood chips, applied in the field of oil-absorbing materials, can solve the problems of poor product quality, low product substitution, and restricting the high value-added utilization of fast-growing eucalyptus wood chips.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

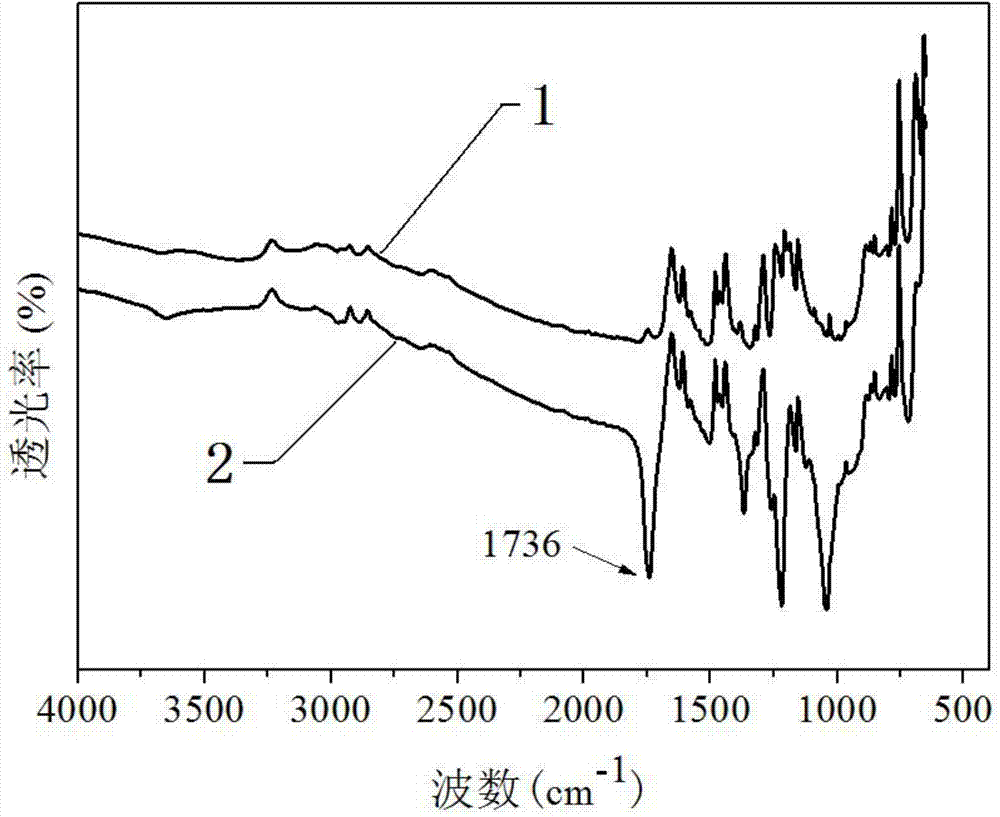

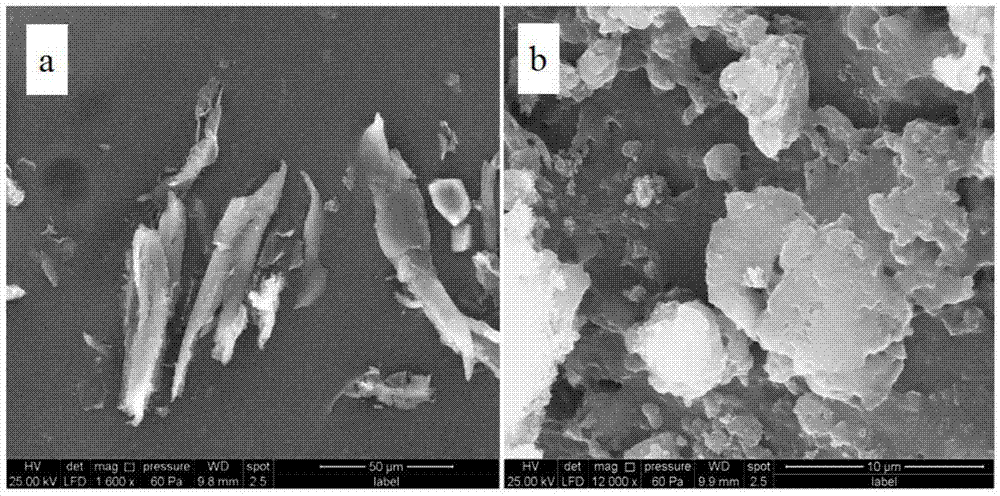

[0022] Put 50g of fast-growing eucalyptus sawdust crushed to 30 meshes into the grinding cylinder of the stirring mill, and grind together with the ball milling medium at a temperature of 50°C to obtain activated sawdust fibers; wherein, the ball milling medium is a 5mm diameter zirconia ball, and the ball milling The volume of the medium stack is 500mL, the rotation speed of the stirring paddle is 400 rpm, and the grinding time is 1 hour;

[0023] Mix 10.00 g of the activated sawdust fiber obtained in step with 50 mL of glacial acetic acid and 60 mL of acetic anhydride, then add 0.5 g of p-toluenesulfonic acid to form a mixed reaction product, the mass volume ratio of wood chips and liquid is 1:11 (g:mL); Stir the mixed reactant formed in step at a temperature of 60°C for 1 hour, then cool to room temperature to obtain a paste mixture;

[0024] Centrifuge the pasty mixture obtained in step at a speed of 3000 rpm, discard the precipitate, add 8 times the volume of deioni...

Embodiment 2

[0027] Put 50g of fast-growing eucalyptus wood chips crushed to 40 meshes into the grinding cylinder of the stirring mill, and grind together with the ball milling medium at a temperature of 50°C to obtain activated sawdust fibers; wherein, the ball milling medium is a zirconia ball with a diameter of 6mm, and the ball milling The volume of the medium stack is 500mL, the rotation speed of the stirring paddle is 375 rpm, and the grinding time is 1.5 hours;

[0028] Mix 10.00 g of activated sawdust fibers obtained in step with 70 mL of glacial acetic acid and 60 mL of acetic anhydride, then add 0.6 g of p-toluenesulfonic acid to form a mixed reaction product, and the mass volume ratio of wood chips to liquid is 1:13 (g:mL); Stir the mixed reactant formed in step at a temperature of 70°C for 2 hours, then cool to room temperature to obtain a paste mixture;

[0029] Centrifuge the pasty mixture obtained in step at a speed of 3000 rpm, discard the precipitate, add 8 times the ...

Embodiment 3

[0032] Put 50g of fast-growing eucalyptus sawdust crushed to 50 meshes into the grinding cylinder of the stirring mill, and grind together with the ball milling medium at a temperature of 50°C to obtain activated sawdust fibers; wherein, the ball milling medium is a zirconia ball with a diameter of 6 mm, and the ball milling The volume of the medium stack is 400mL, the rotation speed of the stirring paddle is 400 rpm, and the grinding time is 1 hour;

[0033] Mix 10.00 g of activated sawdust fibers obtained in step with 60 mL of glacial acetic acid and 50 mL of acetic anhydride, then add 0.7 g of p-toluenesulfonic acid to form a mixed reaction product, and the mass volume ratio of wood chips to liquid is 1:13 (g:mL); Stir the mixed reactant formed in step at a temperature of 80°C for 2 hours, then cool to room temperature to obtain a paste mixture;

[0034] Centrifuge the pasty mixture obtained in step at a speed of 3000 rpm, discard the precipitate, add 9 times the volu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com