Fabric production process

A production process and fabric technology, applied in the direction of fabric surface trimming, singeing, textiles and papermaking, etc., can solve the problems of poor flatness and gloss of finished fabrics, differences in actual hand feel and wearing performance, and complex process flow, and achieve reflection. Regular, orderly arrangement of fibers, and the effect of improving color yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

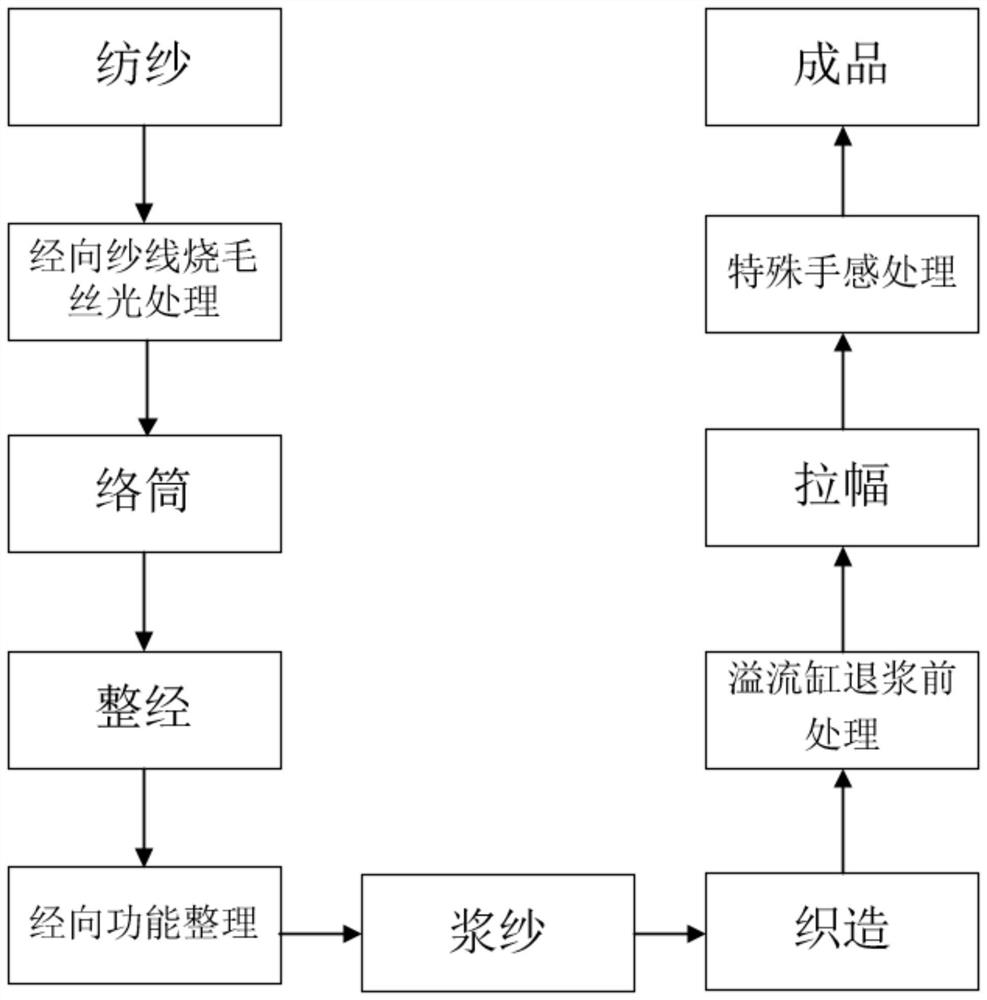

[0031] Such as figure 1 As shown, the present invention provides a kind of fabric production technology, comprises the following steps:

[0032] S1: spinning,

[0033] Make the single yarn go through the twisting process, and twist two or more single yarns together to form a plied yarn to enhance the strength of the yarn. The roving made of spun yarn can retain the style of the roving and increase the yarn. Gloss, thereby improving the gloss and smoothness of the cloth surface.

[0034] Then the plied yarn is wound to a suitable density to form a good package and remove defects and impurities on the yarn.

[0035] S2: Burning wire singeing and mercerizing treatment, which specifically includes,

[0036] S21: passing the plied yarn through the burner of the singeing machine to burn off the fuzz on the surface of the yarn;

[0037] During singeing, the plied yarn passes through the flame at a high speed under a certain tension state. Because the fluff protruding from the sur...

Embodiment 2

[0074] On the basis of embodiment 1, this embodiment comprises the following steps:

[0075] S1: Spinning, winding the yarn to a suitable density, forming a good package and removing defects and impurities on the yarn.

[0076] S2: Singeing and mercerizing treatment of warp burning wire, which specifically includes, S21: passing the plied yarn through the burner of the singeing machine to burn off the hair on the surface of the yarn; during singeing, the plied yarn passes through the flame at a high speed under a certain tension state , because the fluff protruding from the surface has a relatively large heating area, and it will burn when it instantly heats up to the ignition point, while the yarn is twisted and interwoven tightly, and the heating rate is not so fast, so it will not be affected. The yarn after singeing is cleaner, and the finished product has clearer veins and no extra fluff. And S22: mercerizing treatment. The specific process of mercerizing treatment is: y...

Embodiment 3

[0092] On the basis of embodiment 1, this embodiment comprises the following steps:

[0093] S1: Spinning, winding the yarn to a suitable density, forming a good package and removing defects and impurities on the yarn.

[0094] S2: Singeing and mercerizing treatment of warp burning wire, which specifically includes, S21: passing the single yarn through the burner of the singeing machine to burn off the hair on the surface of the yarn; during singeing, the yarn passes through at a high speed under a certain tension The flame, because the fluff protruding from the surface has a relatively large heating area, instantly heats up to the ignition point and burns, while the yarn is twisted and interwoven tightly, and the heating rate is not so fast, so it will not be affected. The yarn after singeing is cleaner, and the finished product has clearer veins and no extra fluff. And S22: mercerizing treatment. The specific process of mercerizing treatment is: yarn arrangement-machine-soa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com