Supercritical CO2 fluid technique based processing method for endowing cellulose fibers with skin whitening function

A technology of cellulose fiber and fluid technology, which is applied in the processing field based on supercritical CO2 fluid technology to make cellulose fiber have whitening function, which can solve the problems of single function, complicated finishing process, and relatively small content of functional content, etc., to achieve The effect of increasing the effective volume, good hand feeling and good sustained release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Supercritical CO 2 Method for fluid loading whitening drug resveratrol to viscose fiber

[0035] First, wash the viscose fabric with ethanol and deionized water, dry and balance for 24 hours and weigh it. Take resveratrol according to 8.5% of the weight of the viscose fabric and put it into the medicine tank of the high-pressure equipment, and add the weight of the viscose fabric 0.1% methanol, then put into the viscose fabric. Cool the CO 2 The gas CO flowing out of the cylinder 2 Cool to liquid.

[0036] The pressure of the high-pressure equipment is first set to 12Mpa, the temperature is 100°C, and the carbon dioxide becomes a supercritical fluid. After impregnating and balancing for 25 minutes, the pressure rises to 30MPa at a speed of 0.5MPa / min; Descending until the end of the experiment, viscose fibers loaded with the whitening drug resveratrol were obtained. The drug loading of viscose fiber was 6.4%.

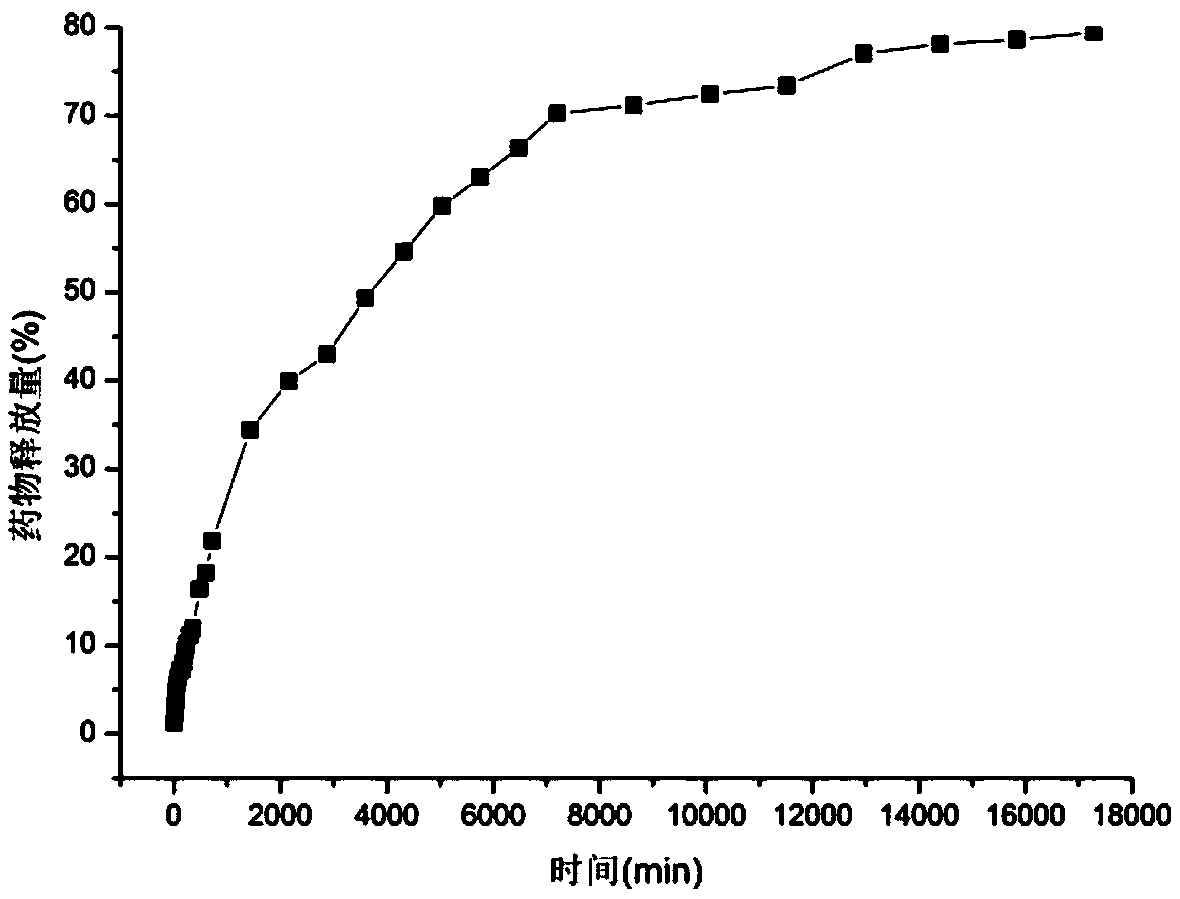

[0037] In order to analyze the sustained-r...

Embodiment 2

[0040] Example 2: Supercritical CO 2 Method for loading whitening drug Piperuminine into cotton fiber by fluid

[0041] Weigh an appropriate amount of cotton fiber, prepare a water-containing ionic liquid 1-butyl-3-methylimidazolium chloride salt as a solution, the water content is 2.5%, immerse the cotton cellulose fiber in it, the bath ratio range is 1:28, set The temperature is 80°C, and the time is 45 minutes.

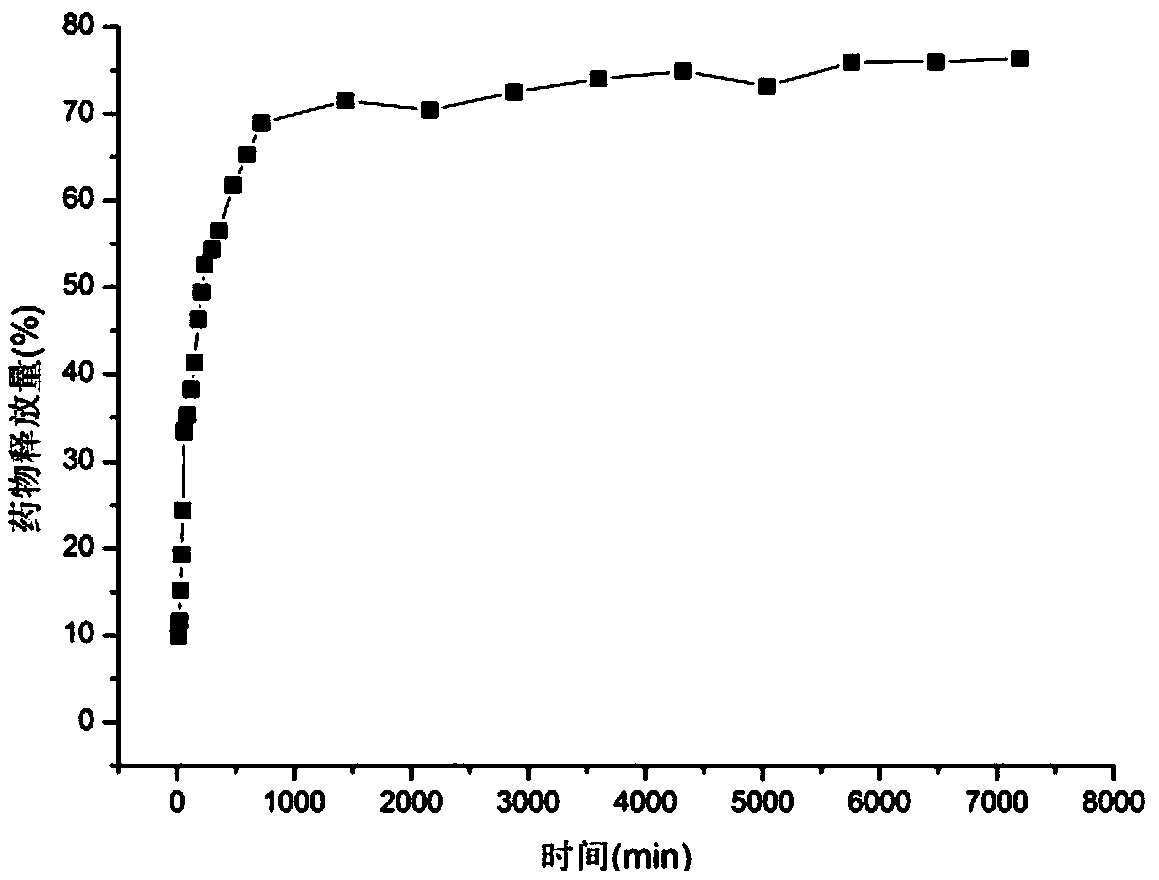

[0042] After the cotton fiber is washed with ethanol and deionized water, it is dried and balanced for 24 hours and weighed. Take by weighing 8.5% of the weight of cotton fiber and put it into the medicine tank of the high-pressure equipment, and add 0.06% of the weight of the cotton fabric. Ethanol, and then into the cotton fiber. Use a cooling tank to cool the gaseous carbon dioxide flowing out of the carbon dioxide cylinder into a liquid. The pressure of the high-pressure equipment is set to 21Mpa, and the temperature is 50°C. of cotton fibers. The drug load...

Embodiment 3

[0046] Example 3: Supercritical CO 2 Method for Fluid Loading Whitening Drug Pantolactone to Tencel Fiber

[0047] First, take an appropriate amount of Tencel fabric, wash it with ethanol and deionized water, dry it for 24 hours and weigh it. Weigh the panlactone according to the weight of Tencel fabric at 9.5%, put it into the medicine tank of the high-pressure equipment, and add Tencel fabric 0.12% ethanol by weight, then put into Tencel fabric. The gaseous carbon dioxide flowing out of the carbon dioxide cylinder is cooled into liquid by cooling tank.

[0048] The pressure of the high-pressure equipment is first set to 12Mpa, the temperature is 100°C, and the carbon dioxide becomes a supercritical fluid. After immersion balance for 25 minutes, the pressure rises to 30MPa at a speed of 1.0MPa / min; Decline, until the end of the experiment, to get loaded with whitening drug pantolactone into Tencel fibers. The drug loading of Tencel fiber is 7.8%.

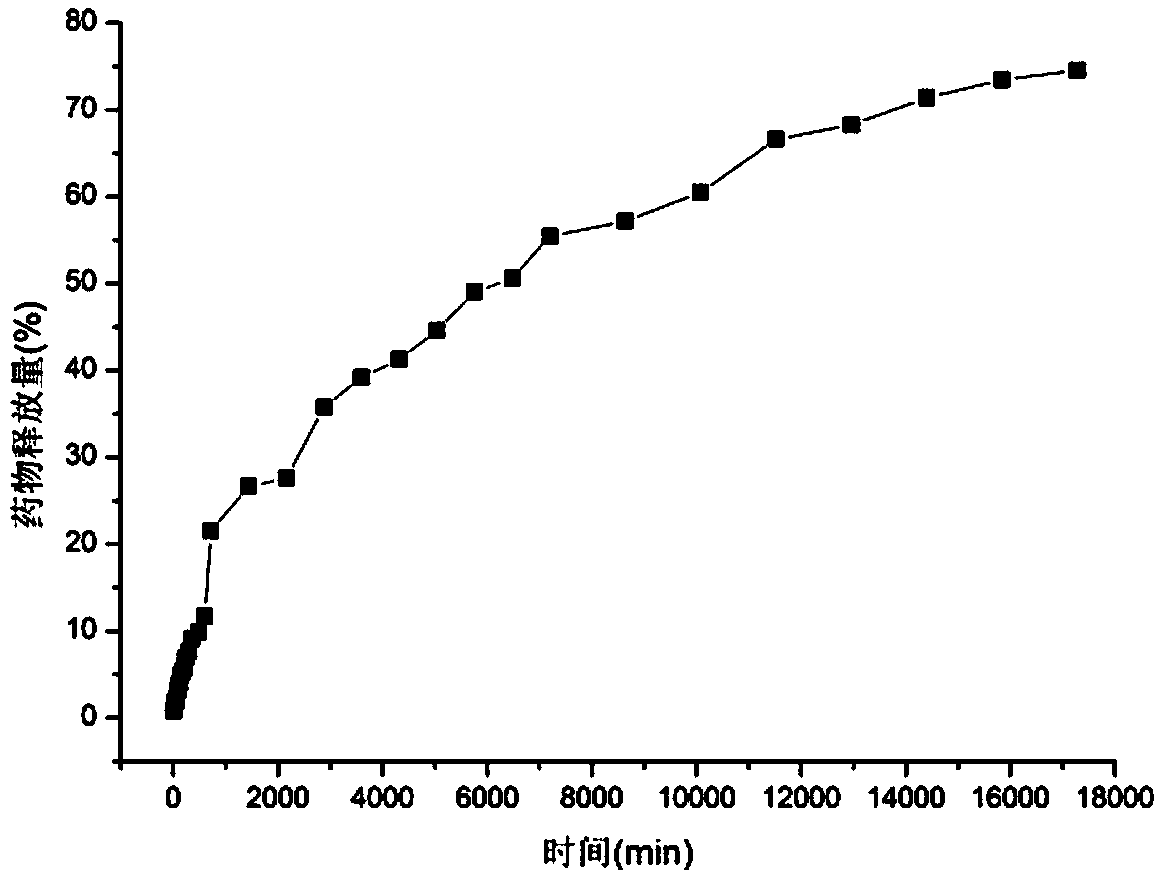

[0049] In order to anal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com